up, use only the correct grade and type of oil,

as given in the “Lubricants, fluids and

capacities” Section of this Chapter; use a

funnel if necessary to prevent spills. After

adding the oil, refit the filler cap hand-tight.

Start the engine, and allow it to idle while the

oil is redistributed around the engine - while

you are waiting, look carefully for any oil leaks,

particularly around the oil filter or drain plug.

Stop the engine; check the oil level again,

after the oil has had enough time to drain from

the upper block and cylinder head galleries.

7 Checking the oil level is an important

preventive maintenance step. A continually-

dropping oil level indicates oil leakage through

damaged seals and from loose connections,

or oil consumption past worn piston rings or

valve guides. If the oil looks milky in colour, or

has water droplets in it, the cylinder head

gasket may be blown - the engine’s

compression pressure should be checked

immediately (see Chapter 2). The condition of

the oil should also be checked. Each time you

check the oil level, slide your thumb and index

finger up the dipstick before wiping off the oil.

If you see small dirt or metal particles clinging

to the dipstick, the oil should be changed.

Coolant

Warning: DO NOT attempt to

remove the expansion tank filler

cap, or to disturb any part of the

cooling system, while it or the

engine is hot, as there is a very great risk

of scalding.

8 All vehicles covered by this manual are

equipped with a sealed, pressurised cooling

system. A translucent plastic expansion tank,

located on the right-hand side of the engine

compartment, is connected by a hose to the

thermostat housing or radiator top hose. As

the coolant heats up during engine operation,

surplus coolant passes through the

connecting hose into the expansion tank. As

the engine cools, the coolant is automatically

drawn back into the cooling system’s main

components, to maintain the correct level.

9 While the coolant level must be checked

regularly, remember that it will vary with the

temperature of the engine. When the engine is

cold, the level should be up to the pipe outlet

on the side of the tank, but once the engine

has warmed up, the level may rise to above

this level.

10 For an accurate check of the coolant level,

the engine must be cold and the level must be

up to the pipe outlet. If it is below this level, the

coolant must be topped-up as follows.

11 First prepare a sufficient quantity of

coolant mixture, using clean, soft water and

antifreeze of the recommended type, in the

specified mixture ratio. If only a small amount

of coolant is required to bring the system up

to the proper level, plain water can be used,

but repeatedly doing this will dilute the

antifreeze/water solution in the system,

reducing the protection it should provide

against freezing and corrosion. To maintain

the specified antifreeze/water ratio, it is

essential to top-up the coolant level with the

correct mixture, as described here. Use only

ethylene/glycol type antifreeze, and do not

use supplementary inhibitors or additives.

Warning: Never remove the

expansion tank filler cap when

the engine is running, or has

just been switched off, as the

cooling system will be hot, and the

consequent escaping steam and scalding

coolant could cause serious injury.

12 If topping-up is necessary, wait until the

system has cooled completely (or at least 10

minutes after switching off the engine, if lack of

time means it is absolutely necessary to top-up

while the engine may still be warm). Wrap a

thick cloth around the expansion tank filler cap,

and unscrew it one full turn. If any hissing is

heard as steam escapes, wait until the hissing

ceases, indicating that pressure is released,

then slowly unscrew the filler cap until it can be

removed. If more hissing sounds are heard,

wait until they have stopped before unscrewing

the filler cap completely. At all times, keep your

face, hands and other exposed skin well away

from the filler opening.

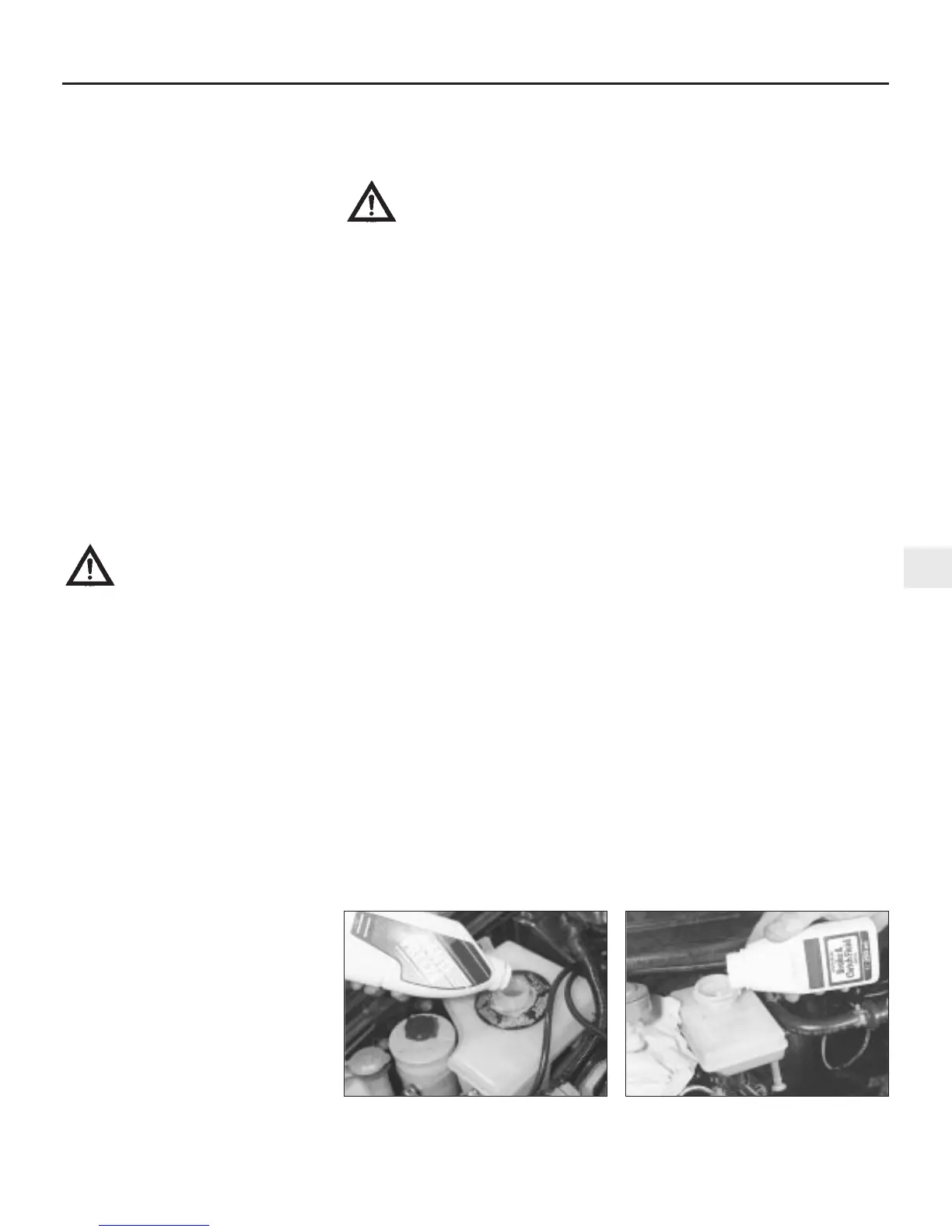

13 When the filler cap has been removed,

add coolant to bring the level up to the outlet

pipe level (see illustration). Refit the cap,

tightening it securely.

14 With this type of cooling system, the

addition of coolant should only be necessary

at very infrequent intervals. If topping-up is

regularly required, or if the coolant level drops

within a short time after replenishment, there

may be a leak in the system.

15 Inspect the radiator, hoses, expansion

tank filler cap, radiator drain plug and water

pump. If no leak is evident, have the filler cap

and the entire system pressure-tested by your

dealer or garage; this will usually show up a

small leak not otherwise visible.

Windscreen/tailgate and

headlight washer fluid

16 Fluid for the windscreen/tailgate/headlight

washer system is stored in a plastic reservoir,

the filler neck of which is located at the right-

hand front corner of the engine compartment.

17 To check the fluid level, release the cap

and observe the level in the reservoir by

looking down the filler neck. In milder

climates, plain water can be used to top-up

the reservoir, but the reservoir should be kept

no more than two-thirds full, to allow for

expansion should the water freeze. In colder

climates, the use of a specially-formulated

windscreen washer fluid, available at your

dealer or any car accessory shop, will help

lower the freezing point of the fluid. Do not

use regular (engine) antifreeze - it will damage

the vehicle’s paintwork.

Battery electrolyte

18 On models not equipped with a sealed

battery (see Section 9), check the electrolyte

level of all six battery cells. The level must be

approximately 10 mm above the plates; this

may be shown by maximum and minimum

level lines marked on the battery’s casing. If

the level is low, use a coin to release the

filler/vent cap, and add distilled water. Install

and retighten the cap.

Caution: Overfilling the cells may cause

electrolyte to spill over during periods of

heavy charging, causing corrosion or

damage. Refer to the warning at the

beginning of Section 9.

Brake fluid

19 The brake fluid reservoir is located on the

top of the brake master cylinder, attached to

the front of the vacuum servo unit. The “MAX”

and “MIN” marks are indicated on the side of

the translucent reservoir, and the fluid level

should be maintained between these marks at

all times.

20 The brake fluid inside the reservoir is

readily visible. With the vehicle on level

ground, the level should be on or just below

the “MAX” mark.

21 Progressive wear of the brake pad linings

causes the level of the brake fluid to gradually

fall; however, when the brake pads are

renewed, the original level of the fluid is

restored. It is not therefore necessary to top-

up the level to compensate for this minimal

drop, but the level must never be allowed to

fall below the minimum mark.

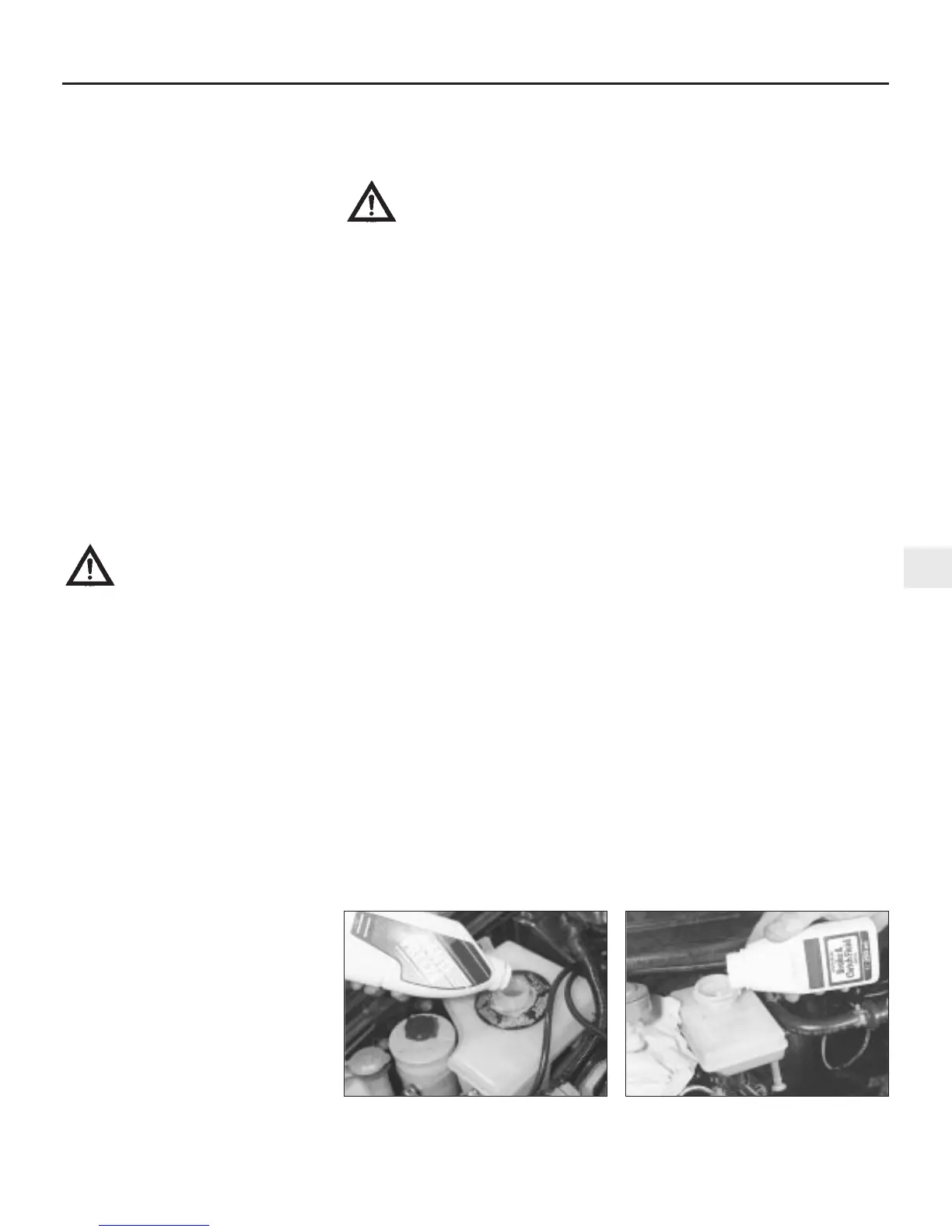

22 If topping-up is necessary, first wipe the

area around the filler cap with a clean rag before

removing the cap - do not invert the cap after

removal. When adding fluid, pour it carefully

into the reservoir, to avoid spilling it on

surrounding painted surfaces (see illustration).

Weekly Checks 1•9

3.22 Topping up the brake master cylinder

reservoir

3.13 Topping up the cooling system

1

1380 Rover 800 Series Remake

Loading...

Loading...