MAINTENANCE

THROTTLE

CONTROL:

CUTTING

UNIT

DRIVE

ADJUSTMENT:

Proper choke and stop switch

operation

is depen-

dant on adjustment

of

remote

controls

~

1. Loosen

outer

cable clamp screw

(A)

on engine

See

Fig. 4.

2.

Set

throttle

control

to

choke

position;

3. Adjust

outer

cable under clamp plate so

that

choke is operated;

4. Tighten clamp plate screw and check -

(a) Choke does

not

operate in fast

position,

and

(b) Stop switch operates

correctly.

CARBURETTOR

ADJUSTMENT:

Refer

to

engine manufacturer's instructions.

LUBRICATION

GENERAL:

Using Clean Engine Oil -

-

All

pivot

points

-

Throttle

control

Cable, See Fig. 4

-- Drive Chains

Note:

All

ball bearings are sealed and require no

maintenance.

GEAR BOX:

This transmission system is

fully

enclosed and

permanently lubricated. No maintenance necessary

CUTTING

UNIT:

Remove spark plug lead and disengage

cutter

drive

. before working on

cutting

unit,

to

prevent acciden-

tal starting

of

the

engine.

Before using machine always inspect

cutting

unit

to

see

that

the

cutting

disc, blades and blade

fixings are

not

worn

or

damaged.

Always check after

striking

a solid object. Do

not

operate machine when unusual

vibration

occurs.

Replace worn or damaged blades in sets

to

preserve

balance.

Remove any build-up

of

grass or clogging

within

the

cutting

unit

or discharge

chute

or

safety flap.

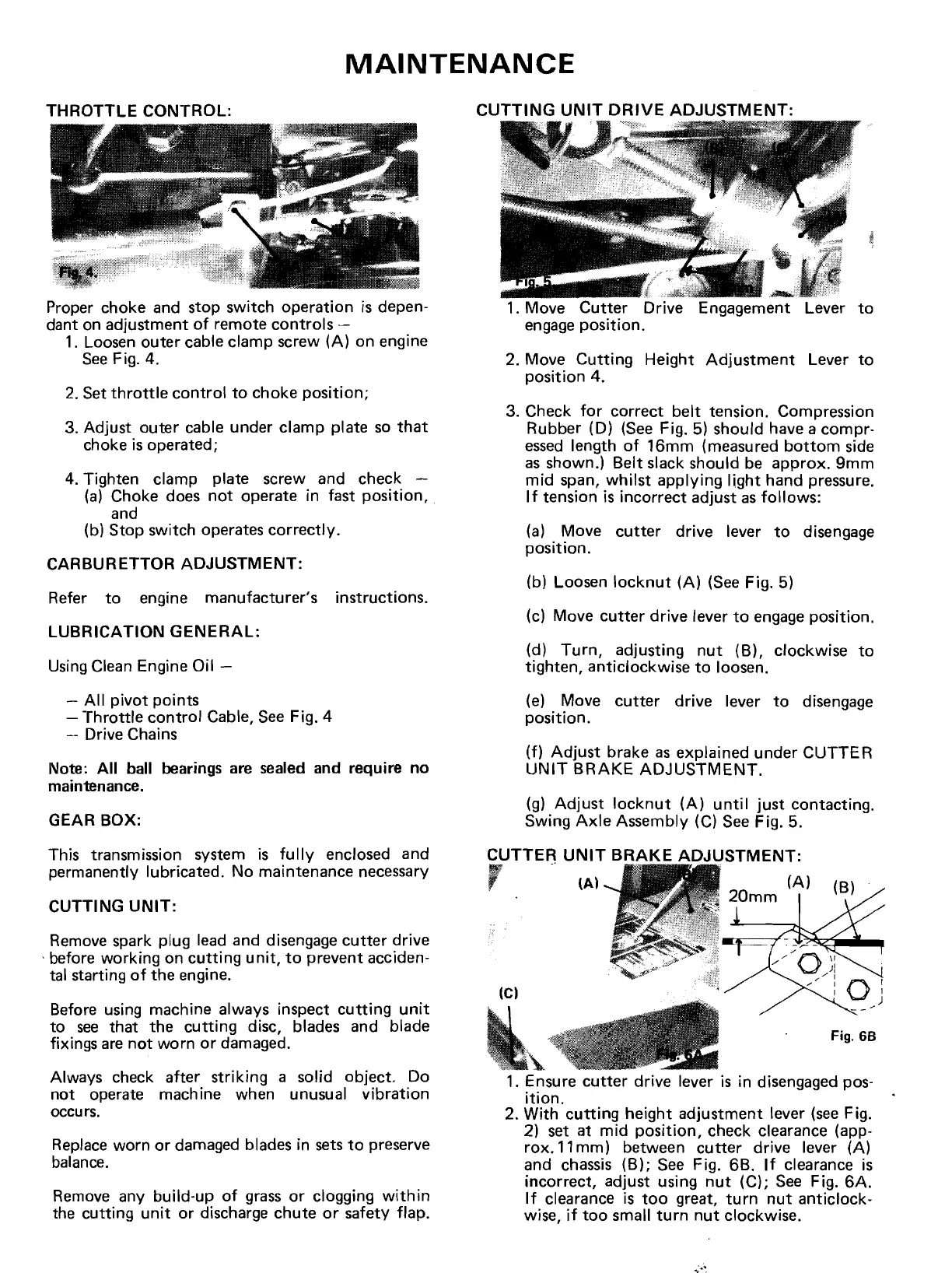

1. Move

Cutter

Drive Engagement Lever

to

engage

position.

2. Move

Cutting

Height

Adjustment

Lever

to

position

4.

3.

Check

for

correct

belt

tension. Compression

Rubber (D) (See Fig.

5) should have a

compr-

essed

length

of

16mm

(measured

bottom

side

as shown.)

Belt

slack should be

approx.

9mm

mid

span,

whilst

applying

Ijght

hand pressure.

If

tension is

incorrect

adjust as

follows:

(a) Move

cutter

drive lever

to

disengage

position.

(b) Loosen

locknut

(A)

(See Fig. 5)

(c) Move

cutter

drive

lever

to

engage position.

(d)

Turn,

adjusting

nut

(B), clockwise

to

tighten,

anticlockwise

to

loosen.

(e) Move

cutter

drive

lever

to

disengage

position.

(f)

Adjust

brake as explained

under

CUTTE

R

UNIT

BRAKE

ADJUSTMENT.

(g)

Adjust

locknut

(A)

until

just

contacting.

Swing

Axle

Assembly (C) See Fig. 5.

CUTTER

UNIT

BRAKE

ADJUSTMENT:

,

-~)

~)

(e)

Fig.

68

1. Ensure

cutter

drive lever is in disengaged pos-

ition.

2.

With

cutting

height

adjustment

lever

(see

Fig.

2) set at

mid

position,

check clearance (app-

rox.

11

mm)

between

cutter

drive lever (A)

and chassis

(B);

See Fig. 6B.

If

clearance is

incorrect, adjust using

nut

(C); See Fig.

6A.

If

clearance is

too

great,

turn

nut

anticlock-

wise,

if

too

small

turn

nut

clockwise.

Loading...

Loading...