OWNER’S MANUAL

9

10

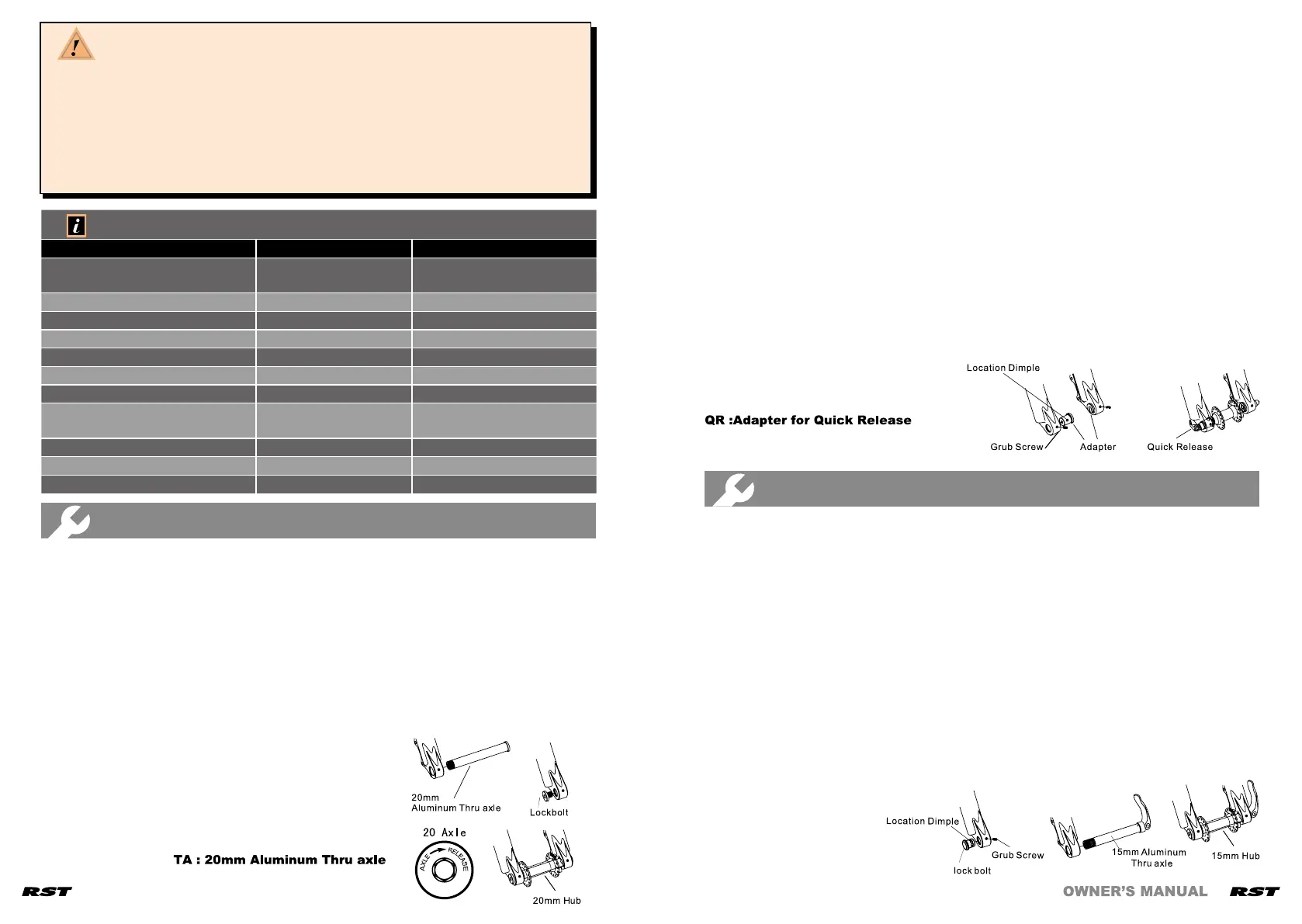

MAX. RECOMMENDATION ROTOR SIZE

MODEL NAME TYPE ROTOR SIZE

KILLAH/ STITCH/

STORM/ ROGUE

POST 203(mm)

SLOPE POST 180(mm)

SPACE IS 203(mm)

RENEGADE POST 180(mm)

TITAN15/ TITAN POST 180(mm)

CHAMP series POST 180(mm)

F1RST series POST 180(mm)

AERIAL Rebound series

AERIAL series

POST 180(mm)

PULSE series POST 180(mm)

VOGUE IS 180(mm)

VIVAir IS 180(mm)

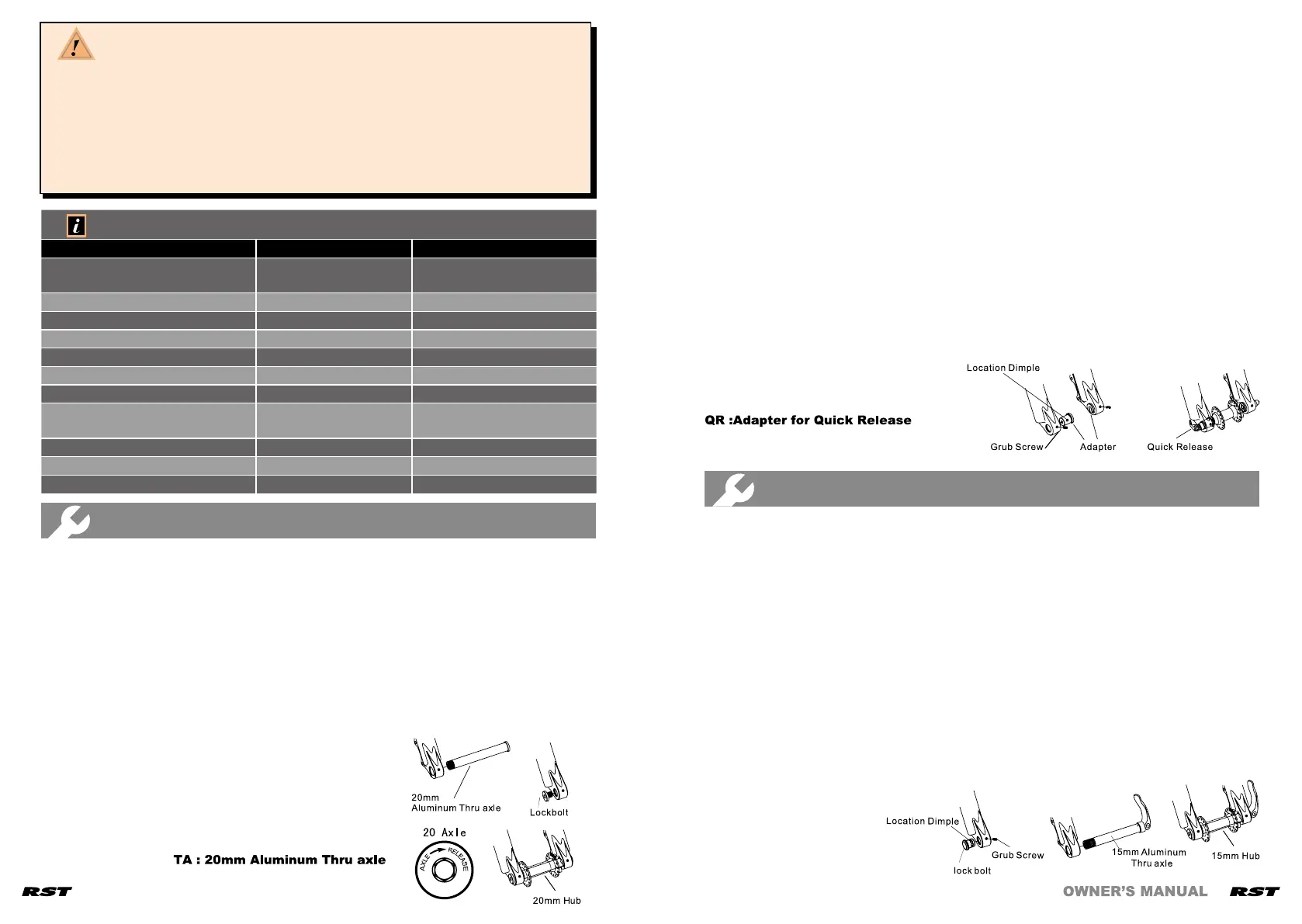

15QR: 15mm Aluminum Quickly Release axle

1. Slide hub into the legs and line up with axle holes.

2. Apply grease or Anti seize to the entire 15mm axle.

3. Slide the 15mm Axle into the fork/hub from the left hand side (Disc side).

4. Gently turn the axle clockwise to connect to the lock bolt threads in the right hand leg.

5. Turn the 15QR axle to the xed position; tighten the 15QR axle to 15Nm by press the

lever.

6. If need to adjust the lever position of the 15QR axle, pull open the lever of 15QR axle

then remove the grub screw then adjust the lock bolt with 15QR axle to the proper

position.

7. 7.Install the grub screw into the ‘’location dimples’’ of the lock bolt, tighten the 15QR

axle to 15Nm by press the lever again. (Taking care to keep the ‘’location Dimples’’ in

line with the grub screw hole in the fork. You should be able to see the location Dimple

by looking down the hole.

8. Check that Disc brake operates correctly.

SPECIAL INSTRUCTION FOR 20MM HUB AND QR

INSTALLATION

Installing 20mm Front Hub

1. Slide hub (including 20mm cones) into the legs and line up with axle holes.

2. Apply grease or Anti seize to the entire 20mm axle.

3. Slide the 20mm Axle into the fork/hub from the left hand side (Disc side).

4. Gently turn the axle clockwise to connect to the axle threads in the right hand leg.

5. Once located V fully tighten the axle to 12-15Nm using an 8mm Hex key.

6. Apply grease or anti seize to the Right Hand side Axle lock bolt.

7. Gently screw-in the lock bolt into the 20mm axle end.

8. Hold the left hand side of the axle with a 8mm Hex key and fully tighten the right hand

side lock bolt to 12-15Nm using a 2nd 8mm Hex Key.

9. Check that Disc brake operates correctly.

Installing QR type Front Hub

1. Identify Adaptor and parts

2. Carefully install grub-screws 3 turns into fork legs-ensuring they are not cross-

threaded. (Note: this may initially be harder than normal, as grub screw may have to

clear some paint residue in the threads from the leg.)

3. Remove the grub-screws.

4. Lightly grease the outside of the adaptors.

5. Install the right hand adaptor into the Right hand leg, taking care to keep the ‘’location

dimples’’ in line with the grub screw hole in the fork. You should be able to see the

location dimple by looking down the fork leg hole.

6. Install the grub screw and tighten gently until it contacts the adaptor.

7. Back-out the grub screw 2 full turns, and the gently try to turn the adaptor.

You should feel a small amount play, between the grub screw head and the adaptor ‘’location

dimple’’-and your small turn should be stopped by the grub screw. If your rotation is not

stopped, it means the grub screw head is not entering the ‘’location dimple’’. Retry. Once you

are convinced that the grub screw is lined up with the ‘’location dimple’’ you can fully tighten

the grub screw to 3Nm.

SAFETY NOTE: It is IMPORTANT that the grub screws are correctly located into the adaptor

dimples ‘’IF NOT’’ the adaptors could rotate and cause a failure.

8. Repeat with Left Hand Adaptor.

SPECIAL INSTRUCTION FOR 15MM QR AXLE INSTALLATION

Instruction of disassemble 20mm thru axle:

1.Use 8mm allen key to loose the bolt in the right leg.

2.Use 8mm allen key to loose the 20mm thru axle.

WARNING

1. Before disassembly of the ‘’function system’’, it is strongly recommended to

take it to an RST dealer. The authorized RST dealers will provide qualified

technicians with proper tools and training to perform service correctly. Improper

disassembly may damage the product and lead to failure of human injury.

2. Before completing maintenance, please make sure all screws have been

securely tightened according the correct torque settings to avoid any human

injury.

Loading...

Loading...