Page 4

Making a Normal Biscuit Cut (Fig. 6~7)

Position your work pieces together and draw a reference

mark at 90

o

to the center point of each proposed joint

location. Space the joints about 4 inches apart.

Separate your work material and clamp each piece securely

to a stable work bench or work table.

Set the biscuit depth selector (6) to correspond with the size

of biscuit you are using. Generally #20 biscuits suit most

applications. If you are using stock that is 16mm thick or

less, you will need smaller biscuits.

Adjust the height of the fence as required and if using the

xed fence rmly tighten height lock knob (5) using nger

pressure only. If using the adjustable fence rmly tighten

angle lock knob (11).

Place one hand on the handle (2) and the other hand on

the motor housing (12).

Place the cutting guide at the center point of each slot in

turn and press the fence against the edge of the work piece

(see gure 6). Make sure the jointer fence is ush to both

sides of your work surface.

Switch on the power switch and push the motor housing

towards the work material. Once the cut is made pull the

motor housing back and allow the return spring to retract the

blade from the slot. Turn the power switch off. Repeat the

procedure until all slots are cut in your work piece.

Cut the slots in the matching piece of work material,

again lining up the center point of each slot and to make

the cuts.

Once all the cuts are complete dry t your biscuits into

your joints and test t your materials to ensure proper

alignment.

Remove the biscuits and insert glue into the slots using a

nozzle applicator or thin wood scrap. It is also helpful to

apply a small amount of glue to the biscuits themselves

before inserting them into the slot.

Place the biscuits in position and clamp your work materials

together until the joint line becomes invisible. Keep your

work materials clamped until the biscuits swell and the

glue sets.

It is possible that thick pieces of timber may require two biscuits

at each location, one at a height of about 1/3 the thickness of

the wood, and the other at about 2/3 the tickness.

NOTE: Unlike other saws and drills, mastering the biscuit joiner

does take some practice. Remember that the ultimate goal is

to achieve a parallel set of cuts in your work surface. If you

nd yourself making uneven cuts, you are probably working

too fast. Make sure of these points:

When the tool powers on it might vibrate out of position.

Prior to making a cut make sure the center of the tool is

aligned with the center of your cut mak.

Make sure the height lock knob is rmly tightened.

Go slow - visually make sure you have the joiner lined up

with your cut mark and most importantly that the fence is

ush with both the top and side edge or your work material

prior to making the cut. Once these are accomplished then

make the cut. Patience and practice are the keys to creating

perfect joints.

OPERATION

ADJUSTMENTS

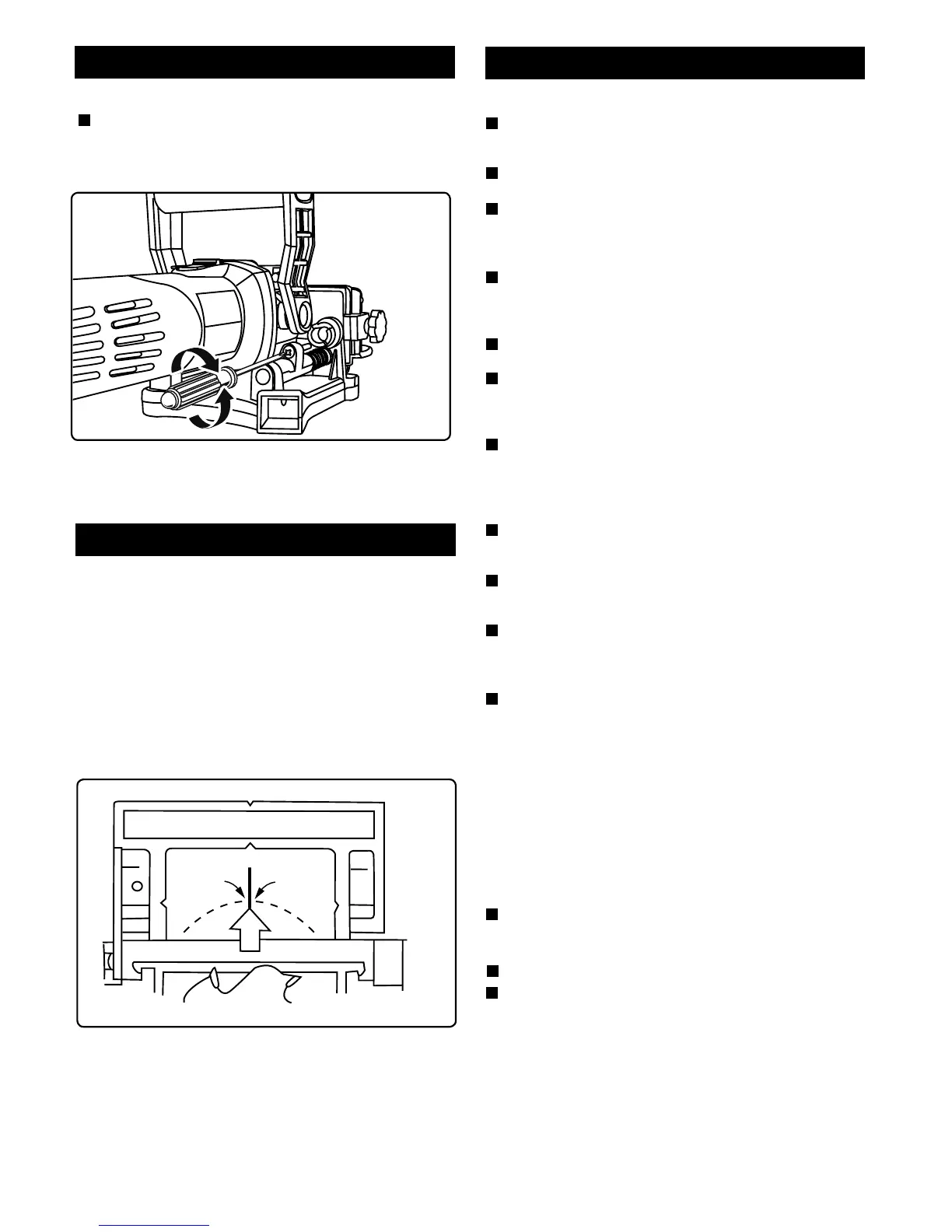

Fine Depth Adjustment (Fig. 4)

All biscuits are manufactured to slightly different sizes, so

you might need to adjust the depth of cut on the tool. The

depth adjustment rod (7) can be rotated to increase or

decrease the depth of cut.

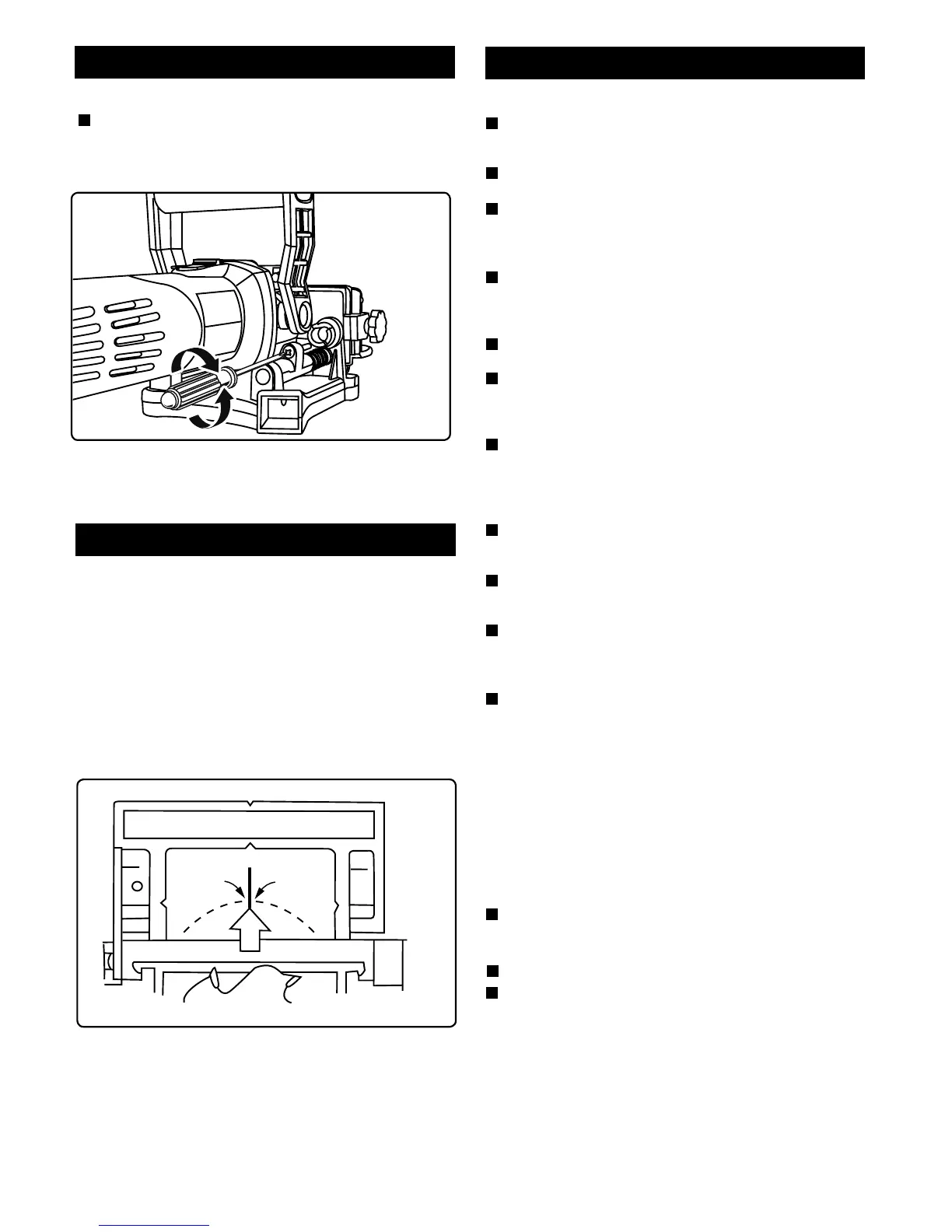

Biscuit jointers can be used for making various types of strong,

accurate joints in pieces of timber or wood sheeting.

To cut the biscuit slot the body of the jointer is moved toward

the material after alignment, by utilizing the various features of

the Biscuit Joiner you can create a wide range of different types

of joints. Always make a reference line to line up the machine

with the center of the material to be plunged to ensure accurate

biscuit placement (Figure. 5 - Please note in the picture the

center of the adjustable fence is omitted in order to better

explain the joining process).

OPERATION

Loading...

Loading...