20

Installation Procedure

English

Installation Procedure

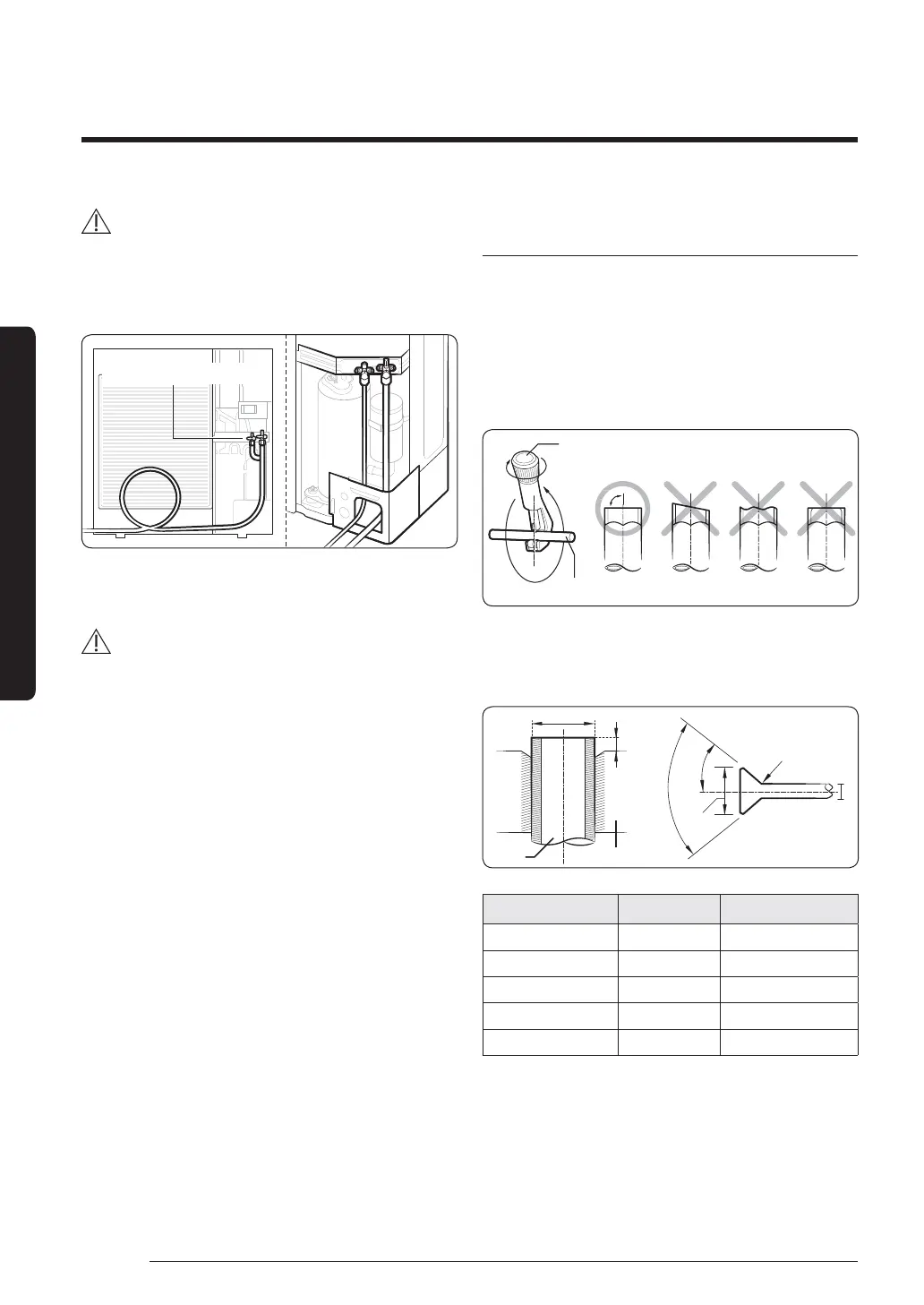

CAUTION

• Be sure to use C1220T-1/2H (Semi-hard) pipe for

more than Ø19.05 mm. If you use C1220T-O (Soft)

pipe for Ø19.05 mm, the pipe may be broken, which

can result in an injury.

Make at least one round:

It will reduce noise and vibration

• The appearance of the unit may be different from the

diagram depending on the model.

CAUTION

• After connecting the pipes with knock-out treatment,

plug the space around the pipes.

• After connecting the pipes, proceed exactly as

directed in the guide to prevent interference with the

internal parts.

• Tighten the nuts to the specified torques. If

overtightened, the nuts could be broken so

refrigerant may leak.

• Protect or enclose refrigerant tubing to avoid

mechanical damage.

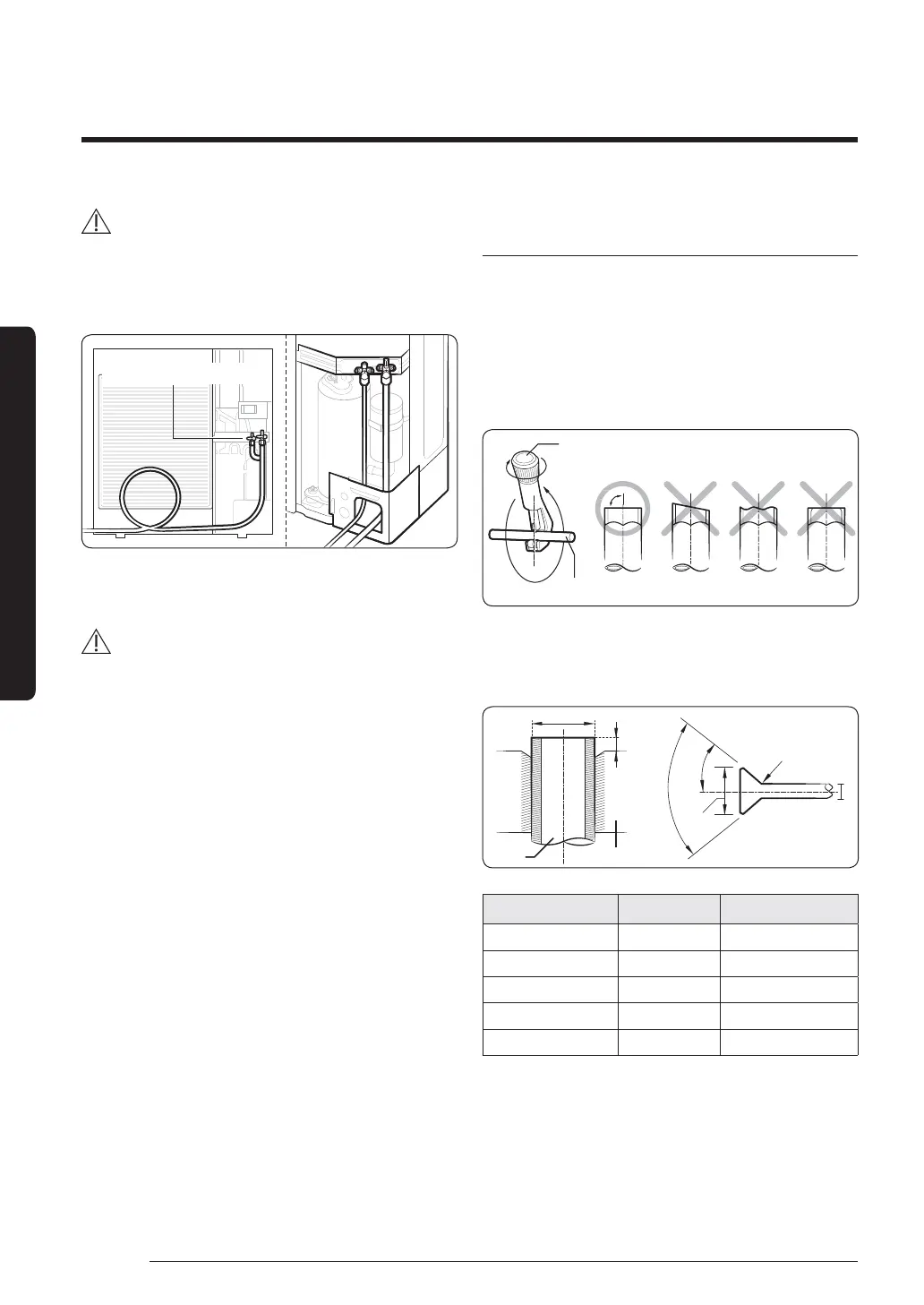

Step 6 Optional: Cutting and aring the

pipes

1 Make sure that you have the required tools available.

(pipe cutter, reamer, flaring tool, and pipe holder)

2 If you wish to shorten the pipes, cut it with a pipe

cutter, taking care to ensure that the cut edge remains

at a 90° angle with the side of the pipe. Refer to

the illustrations below for examples of edges cut

correctly and incorrectly.

Pipe cutter

Pipe

90°

Oblique

Rough

Burr

3 To prevent any gas from leaking out, remove all burrs

at the cut edge of the pipe, using a reamer.

4 Slide a flare nut on to the pipe and modify the flare.

D

A

D

45° ±2°

90° ±2°

Pipe

Flare

Flare

R 0.4 to 0.8 mm

L

Outer diameter (D) Depth (A) Flare dimension (L)

ø6.35 mm 1.3mm 8.7 to 9.1 mm

ø9.52 mm 1.8mm 12.8 to 13.2 mm

ø12.70 mm 2.0mm 16.2 to 16.6 mm

ø15.88 mm 2.2mm 19.3 to 19.7 mm

ø19.05 mm 2.2mm 23.6 to 24.0 mm

Loading...

Loading...