17

Pipe brazing instructions and cautions

Keeping refrigerant pipe clean and dry

X To prevent foreign materials or water from entering the pipe, it is important to keep the refrigerant pipe clean, dry and

sealed during installation.

Exposure place Exposure time Sealing type

Outside exposure

Longer than one month Pipe pinch

Shorter than one month Taping

Inside exposure - Taping

Brazing the pipe

X Make sure that there is no moisture inside the pipe.

X Make sure that there are no foreign materials and impurities in the pipe.

X Make sure that there is no leak.

X Make sure to follow the instruction when brazing the pipe.

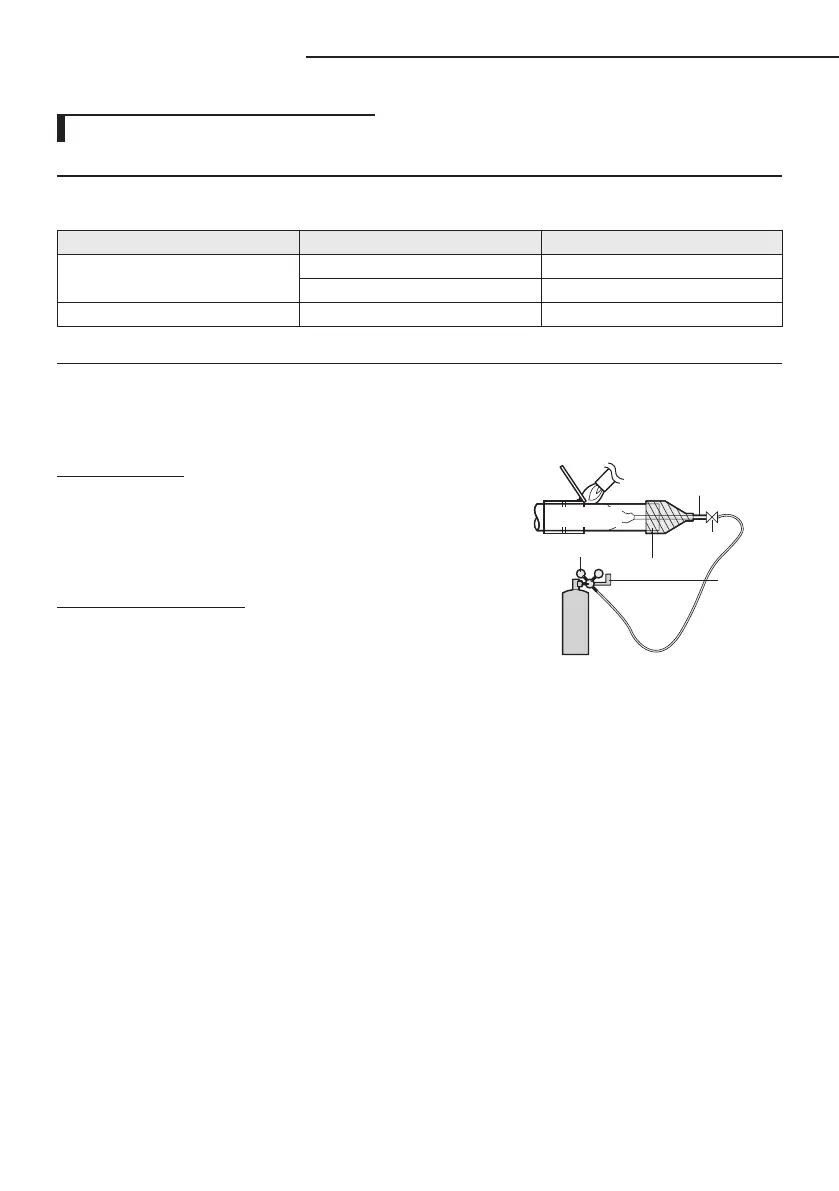

The use of Nitrogen gas

1. Use Nitrogen gas when brazing the pipes as shown in the picture.

2. If you don’t use Nitrogen gas when brazing the pipes, oxide may form

inside the pipe. It can cause the damage of the compressor and valves.

3. Adjust the ow rate of the nitrogen gas with a pressure regulator to

maintain 0.05m/h(1.77ft/h) or less.

Direction of the pipe when brazing

• Performing the brazing of the pipe should be headed downwards or

horizontally.

Brazing part

1/4" copper pipe

Stop valve

Taping

Pressure regulator

Nitrogen gas

Flowmeter

Refrigerant piping

ki]_TW]`WZhTW\pttj|GrniluRmyUGGGX^ YWYYTXXTYYGGG㝘㤸G_a\_a\`

Loading...

Loading...