INSTALLING THE INDOOR UNIT

Cutting/Extending the Piping

Make sure that you have the required tools available (pipe cutter, reamer,

flaring tool and pipe holder).

1

To prevent any gas from leaking out, remove all burrs at the cut end of the

pipe, using a reamer.

3

Slide a flare nut on to the pipe and modify the flare.

4

Align the pipes to be connected and tighten the flare nuts first manually and

then with a torque wrench, applying the following torque.

6

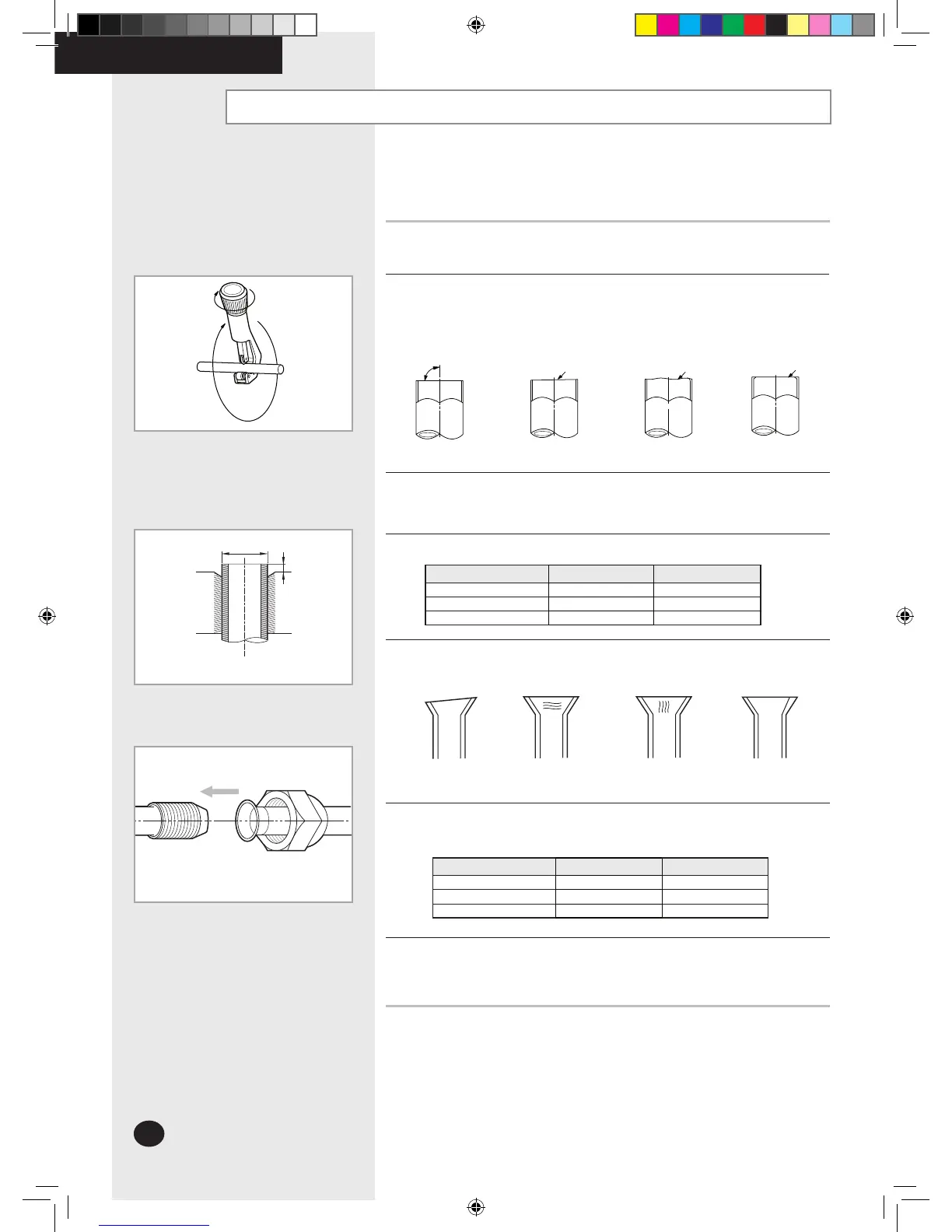

Check that the flaring is correct, referring to the illustrations below for examples of incorrect

flaring.

5

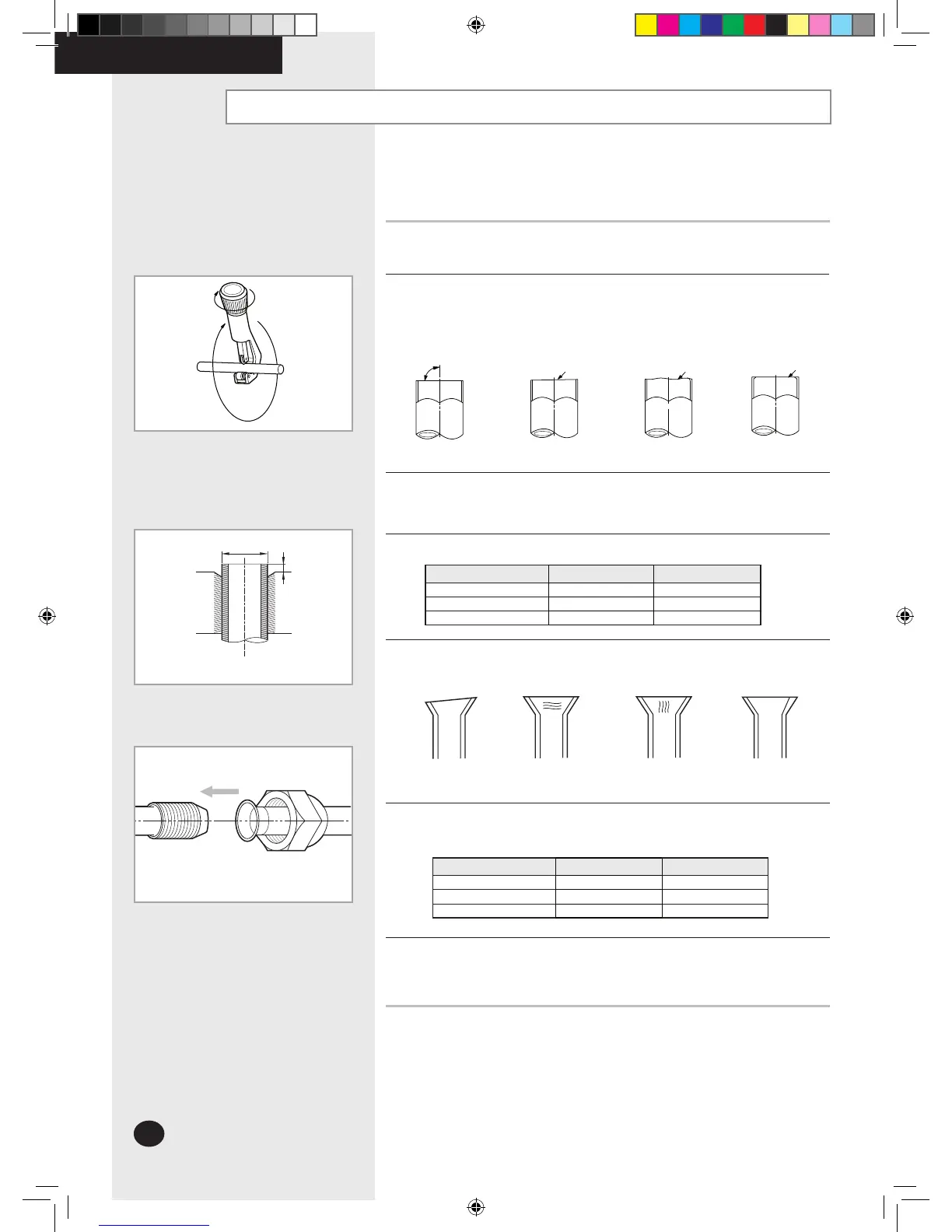

If you wish to shorten the piping, cut it using a pipe cutter, taking care to

ensure that the cut edge remains at a 90° angle with the side of the pipe,

and referring to the illustrations below for examples of edges cut correctly

and incorrectly.

2

Oblique Rough

Burr

Inclined Damaged Surface Cracked Uneven Thickness

D

A

For further details on how to connect up to the outdoor unit and purge the circuit, refer to

page 23.

7

In case welding the pipe, the gas nitrogen must be blown into the parts.

Outer Diameter (D)

Thickness

Depth (A)

ø6.35 mm 0.8mm 1.3 mm

ø9.52 mm 0.8mm 1.8 mm

ø12.70 mm 0.8mm 2.0 mm

Outer Diameter Thickness Torque (kgf•cm)

ø6.35 mm 0.8mm 140~170

ø9.52 mm 0.8mm 250~280

ø12.70 mm 0.8mm 380~420

Loading...

Loading...