10 S&C Instruction Sheet 711-590

Inspection Recommendations

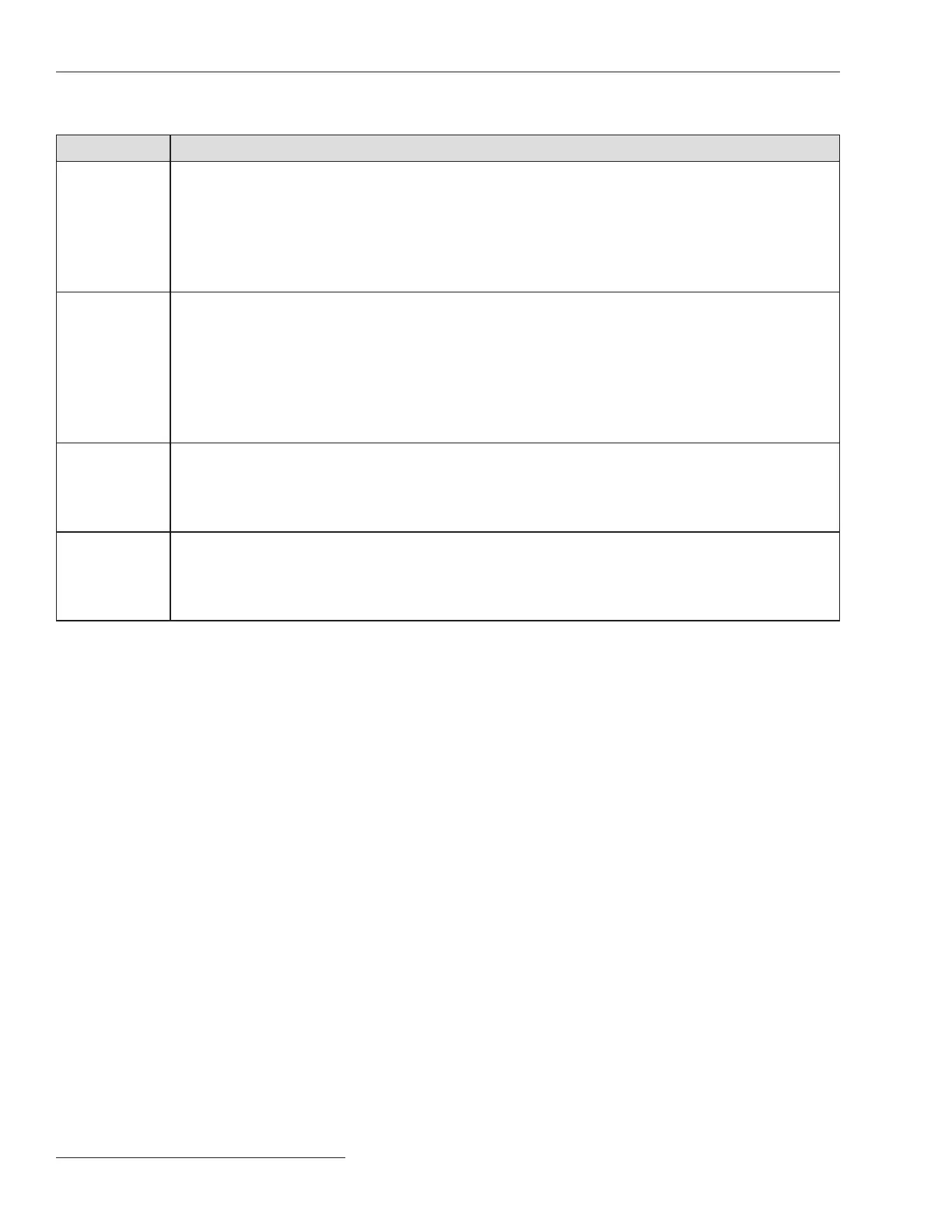

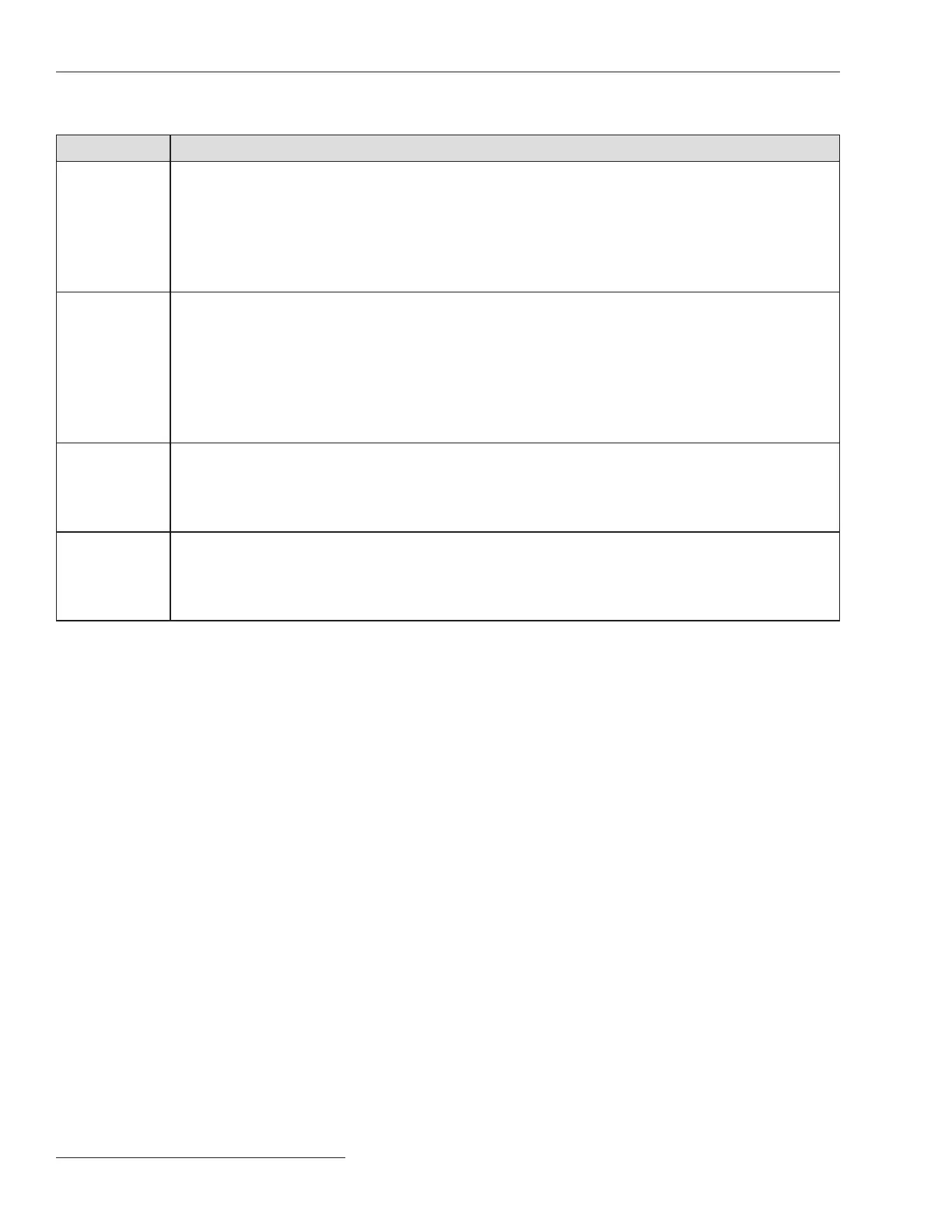

Table 2� Recommended Inspection Procedures for S&C Mark V Circuit-Switcher Components—Continued

Component Inspection Procedures

Disconnect

live parts

1� Check for evidence of damage, excessive corrosion, or wear—especially at the fault-closing contacts and current-carrying contacts�

Replace current-carrying jaw contacts if the silver-alloy inserts on two or more contact fingers are worn to the extent the blade

tongue contact engages the full width of the contact finger�

2� Check the fastener tightness on current-carrying parts�

3� Observe operation during slow, manual cranking using the switch operator manual operating handle� Check for proper contact

alignment�

4� Lubricate the contact surfaces with an appropriate lubricant�①

Pre-insertion

inductor

1� Clean the exterior finish of inductor windings using a mild soap and water solution and a soft cloth� Inspect the fiberglass roving for

damage or wear� Use a mild soap and water solution and a clean cloth to clean the exterior finish of the inductor winding� While

cleaning the windings, inspect for damage or exposure of the fiberglass roving�

2� If the fiberglass roving is damaged, use the touch-up kit, S&C catalog number SA-42721, to refinish any damaged surfaces� First,

thoroughly wire-brush the surface to be refinished� Then, sand with No�1 sandpaper and No�0 sandpaper to create a smooth surface�

Brush on the paint according to the directions on the label and let dry for six hours� If the coiled conductor beneath the fiberglass

roving is exposed, remove the inductor from service and contact your nearest S&C Sales Office for a replacement.

3� Inspect the moving and stationary arcing rods to verify their proper setting� Replace the arcing rods if they show significant wear or

erosion�

Bypass

accessory

1� Check for evidence of damage, excessive corrosion, or wear�

2� Check the fastener tightness on current-carrying parts�

3� Observe operation using the stick-operated ratchet mechanism� Check for proper contact alignment�

4� Lubricate the contact surfaces with an appropriate lubricant�①

Grounding switch

1� Check for evidence of damage, excessive corrosion, or wear— especially at the jaw-contact members�

2� Check the fastener tightness on current-carrying parts�

3� Observe operation using manual operating handle� Check for proper contact alignment�

4� Lubricate the contact surfaces with an appropriate lubricant�①

① Shell Gadus® S2 U1000 2 Lubricant, catalog number 9999-043, is

available in 1 oz� tubes from S&C� Shell Darina SD2, Dow 33, or equivalent

can be substituted�

Resistance Values

The allowable resistance values indicated in Table 3 on

page 11 and Table 4 on page 12 are provided for the

convenience of users whose practices include measuring

and recording the resistance over current-carrying and

current-interrupting components of a circuit-switcher.

Such measurements are not required to fulll the terms

of S&C’s circuit-switcher warranty and should only be

made by qualied personnel fully trained in the measur-

ing equipment and the techniques for making resistance

measurements on high-voltage equipment. The measure-

ments can be used to identify areas of high resistance, to

be remedied by cleaning and maintenance, or component

replacement.

Loading...

Loading...