- 4 -

1. HEAD REPLACEMENT

• After replacement, demagnetize the heads by using a degausser.

• Be sure to clean the heads before attempting to make any adjustments.

• All wiring should be returned to the original position after work is completed.

TAPE DECK ADJUSTMENTS

2. HEAD AZIMUTH ADJUSTMENT

(1) Load the test tape(VTT-703, etc., 10 kHz) for azimuth

adjustment.

(2) Press the PLAY button.

(3) Use a cross-tip screwdriver to turn the screw for azimuth

adjustment so that the left and right output are maximized.

(4) Press the STOP button.

(5) After completion of the adjustment, use thread lock(TB-1401B)

to secure the azimuth-adjustment screw.

4. MOTOR SPEED ADJUSTMENT

(1) Insert the test tape(TCC-119, etc., 3,000 Hz).

(2) Press the PLAY button.

(3) Use a flat-tip screwdriver to turn the SVR(located inside the

rear of the motor) to adjust SVR so that the frequency counter

become 3,000 Hz.

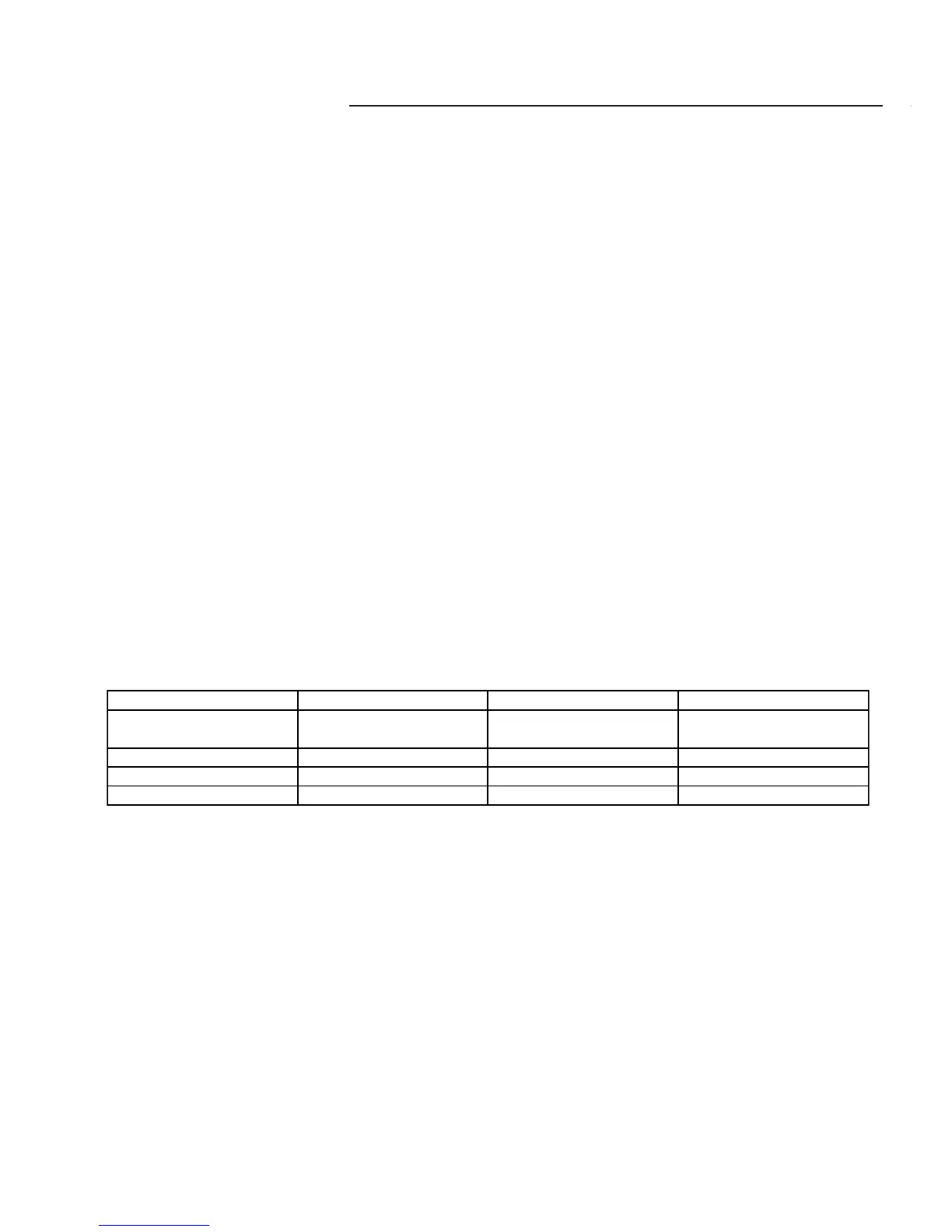

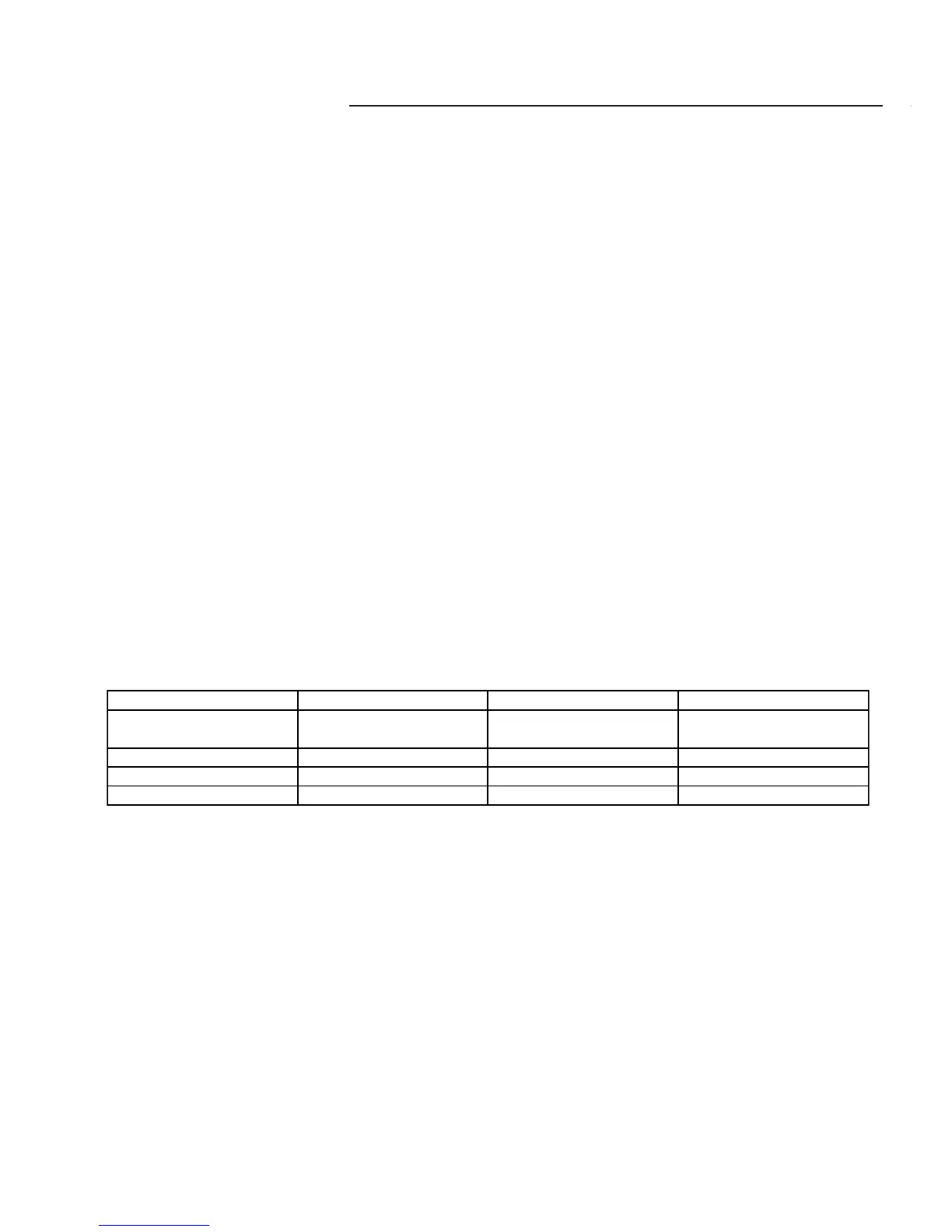

5. CHECKING THE MECHANISM TORQUES AND TENSION

• Clean the head, capstan and pinch roller before making any measurement.

Measurement Take-up torque Back tension Tape tension

Cassette for PLAY : TW-211A PLAY : TW-2111A Driver-power cassette

measurement FF,REW : TW-2231 TW-2412

PLAY 30 - 60 gr.cm 2.0 - 4.5 gr.cm 60 gr.cm or more

F.FWD 55 - 120 gr.cm ----- -----

REW 55 - 120 gr.cm ----- -----

3. AC BIAS FREQUENCY ADJUSTMENTS.

(1) Connect counter to T201(BS).

(2)R/P switch in recording state.

(3) Adjusting T801 use a plastic screw, AC bias frequency : 50 kHz

Loading...

Loading...