22 GB

Set-up

Prepare the workplace where the machine is to be placed.

Insure sufcient room to allow safe work without malfunc-

tions. The machine is designed to operate in closed rooms

and must be placed stabily on rm level ground. Stability

is insured by attachment to the ground with 4 screws (Fig.

14).

Transport

The machine may only be transported with suitable lifting

devices (crane or fork lift). The connection point for the

rope (crane) is on the upper band wheel cabinet.

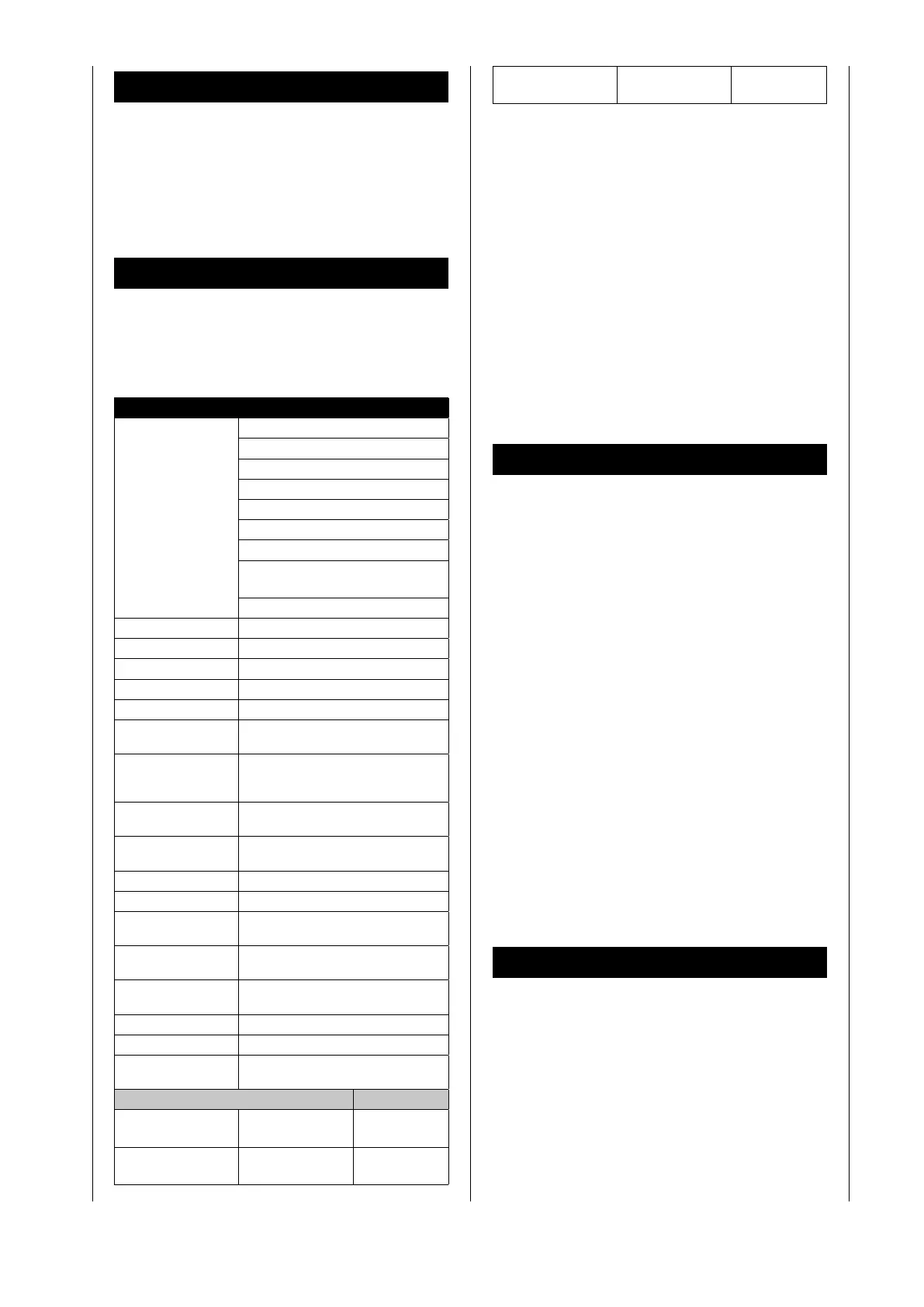

BASA3 (1901503901) / BASA3 (1901503902)

Scope of delivery Band saw

Sawing table

Longitudinal stop

Dust bag connector

Push stick

Accesory Bag

Hexagonal spanner SW 10/13

Hexagonal socket head wrench

SW 4/SW 5

Operating instructions

Passage width 306 mm

Passage height 205 mm

Table size 400 x 548 mm

Cutting speed 370 – 750 m/min

Saw band length 2360 mm

Height up to tab-

letop

490 mm

Height up to table-

top with

underframe

1025 mm

Overall height with-

out underframe

1125 mm

Overall height with

underframe

1655 mm

Overall width 900 mm

Overall depth 540 mm

Slewing range of the

table

-8° – +45°

Overall weight with-

out underframe

69 kg

Overall weight with

underframe

79 kg

Suction connector Ø 100 mm

Extraction power 565 m

3

/h

stat. under pressure

(20 m/sec)

900 Pa

Drive

Motor Alternating

current 230-240V

Rotary current

400V 3phase

Nominal consump-

tion P1 (kW)

0,8kW (S1)

1,1 kW (S6 40%)

0,7kW (S1)

1,1kW (S6 40%)

Delivery of power P2

(kW)

0,56 kW (S1)

0,74kW (S6 40%)

0,48 kW (S1)

0,77kW (S6 40%)

Noise parameters

The noise emission values determined accordin

g to EN 23746 for the sound level and according to EN

31202 (coefcient of correction k3 calculated according

to Appendix A.2 of EN 31204) for the sound level at the

workplace are as follows, based on the working conditions

listed in ISO 7904 Appendix A:

Sound level in dB

Idle running LWA = 80.3 dB(A)

Operation LWA = 100.2 dB(A)

Sound level at the workplace in dB

Idle running LpAeq = 64.1 dB(A)

Operation LpAeq = 82.9 dB(A)

A measurement uncertainty allowance K = 4 dB applies to

the mentioned emission values.

Machine description

Due to its perfected design, the machine offers a versatile

application for processing wood and plastics in the work-

shop.

The upper and lower bandwheel is protected by a xed

guard and an articulated cover. Upon opening the cover,

the machine is switched off. Switching on again is only

possible with the cover closed. The non-cutting part of the

sawbelt above the table top is covered by a guard xed

to the sawbelt guide, the latter being protected against

inadvertant opening by the xed guard of the upper band

wheel. The non-cutting part of the sawbelt under the table

top is protected by a xed cover.

The swivelling range of the table from -20° to +47° allows

versatile cutting possibilities (e.g.)

• Longitudinal cuts

• Cross cuts

• Diagonal cuts

• Curved and irregular cuts

• Cuts for dovetails and tenons

• On-edge cuts of squared beams

Please consult also the working hints in the operating in-

structions.

Completion

Assembly tools

1 engineer’s wrench SW 10/13

For reasons of packaging technology, the tabletop, the

handle, and the handwheel are not mounted.

Installation of the Underframe, Fig. 1.1

1. Put a wooden block behind the machine, and than

carefully turn over the machine so that the base plate

lies on the oor.

2. Loosely screw the frame feet with 12 screws (M6 x 12)

to the base plate.

Loading...

Loading...