english 13

• Turnthesawtotheside

• ApplyagenerousamountofSAE20oiltotheshaftend

and bronze bearings.

• Letthelubricantoilworkinovernight.

• Repeattheprocedurethenextdayontheothersideof

the saw.

EC Declaration of Conformity

We herewith declare, scheppach Fabrikation von Holzbearbeitungs-

maschinen GmbH, Günzburger Str. 69, D-89335 Ichenhausen that the

machine described below due to its con struc tion and design and in

the version delivered by us complies with the relevant provisions of

thefollowingECDirectives.

Incaseofamodicationofthemachinethisdeclarationceasestobe

valid.

Machine description:

Scroll Saw

Machine type:

deco 401, deco 402, deco-tronic

Art.Nr.88001904,88001905,88001914,88001906

RelevantECdirectives:

EC machine directive 98/37/EG (< 28.12.2009),

EC machine directive 2006/42/EG (> 29.12.2009),

EC Low voltage directive 2006/95/EWG,

EC-EMV directive 2004/108/EWG.

NotiedbodywithinthemeaningofAnnexVII

TÜV Rheinland, Sicherheit und Umweltschutz GmbH, 51101 Köln

Place, date:

Ichenhausen, 13.07.2009

Signature:

On behalf of Wolfgang Windrich (technical director)

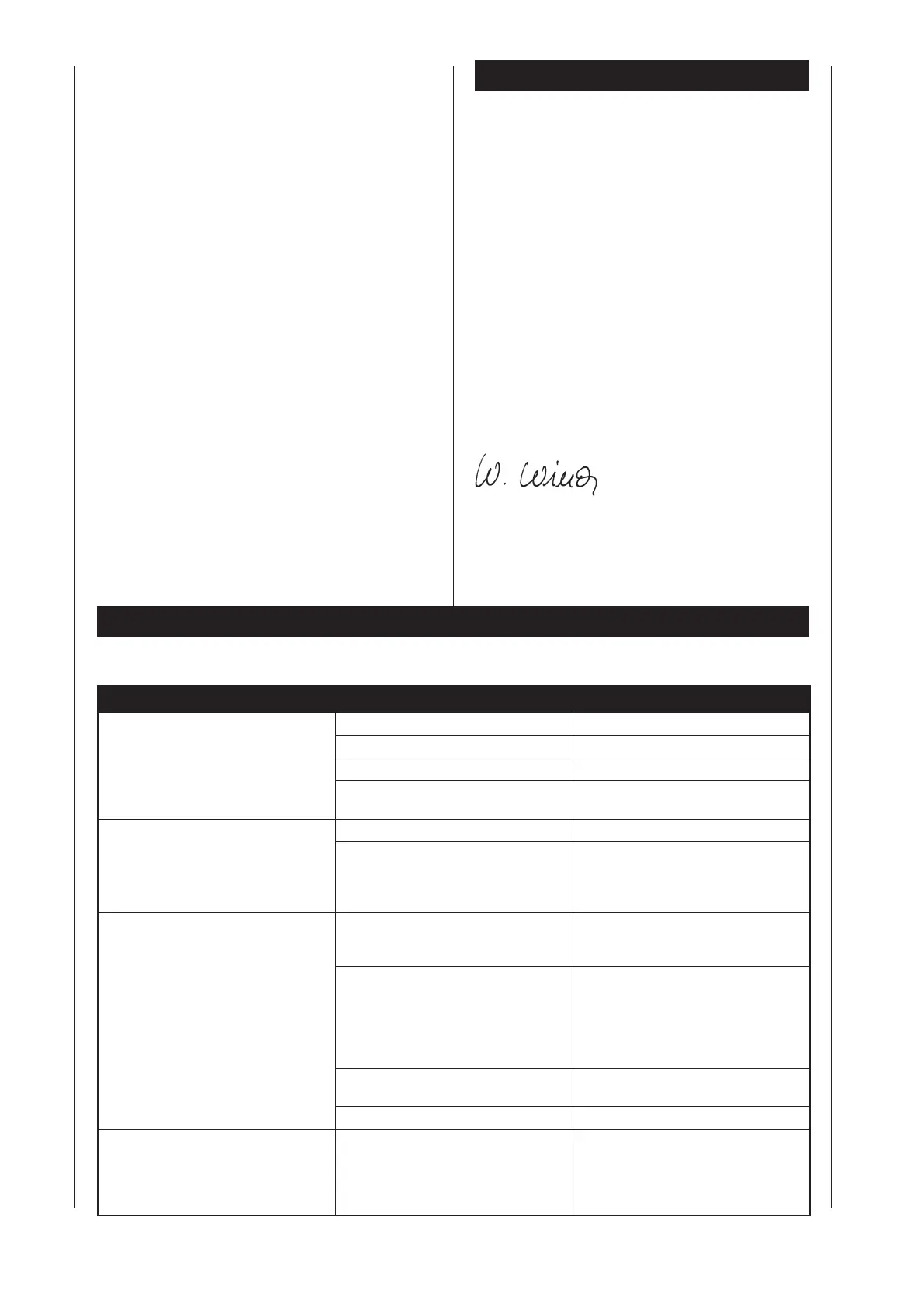

Troubleshooting table

Warning: In the interests of operational safety, always switch off the saw and remove the mains plug before carrying out maintenance

work.

Fault Possible causes Action

Saw blades break Tension incorrectly set Set the correct tension

Load to great Feed the workpiece more slowly

Incorrect saw blade variety Use the correct saw blades

Workpiece not fed straight Avoid exerting pressure from the

side

Motor does not function Mains Gable faulty Changefaultyparts

Motor faulty Callcustomerservice.Donot

attempt to repair the motor yourself

as this should be carried out by

trained personnel.

Vibration

NOTE:Thesawvibratesslightly

when the motor is running in

normal operation.

Saw incorrectely installed Refertotheinstructionsgiven

earlier in this manual for

information on installing the saw

Unsuitable underlay The heavier the work bench is,the

less the vibration. A bench made

from ply wood always vibrates more

than one made from solid wood.

Select the work bench best suited

to your working conditions

The work bench is not screwed

down or is on the motor

Tighten the locking lever

The motor is not secured Securely screw the motor in place

Saw blade swings out

Holders not aligned straight

Holders not aligned Losen the screws with which the

holders are fastenedto the arm.

Align the holders so that they are

perpendicular to each other and

retighten the screws.

Loading...

Loading...