40 GB

A properly sharpened chain goes way through the

wood and it requires very little pressure. Do not work

with a dull or damaged chain. It increases physical

exertion, increase the vibrations and leads to unsat-

isfactory results and higher wear.

• Clean the chain.

• Check it.

• Replace damaged or worn parts with matching

spare parts they are in the shape and size of the

original parts as necessary.

• Sharpening a chain should be performed only by

experienced users!

• Notice. Below the angle and dimensions If the

chain is not properly sharpened or the depth is too

small, there is a higher risk of reversion effects and

resulting injuries!

• The chain cannot be xed on the guide rail. It is

therefore best to remove the chain from the rail

and then sharpen.

• Select the appropriate tools for the chain pitch

sharpening tool. See "Specications" for the al-

lowed chain pitches.

The chain pitch (for example 3/8 ") is highlighted in

the depth of each blade. Use only special les for

chain saws! Other les have the wrong shape and

the wrong cut. Select the le according to the diam-

eter of your chain pitch. Make sure to observe the

following angle when sharpening the chain diameter.

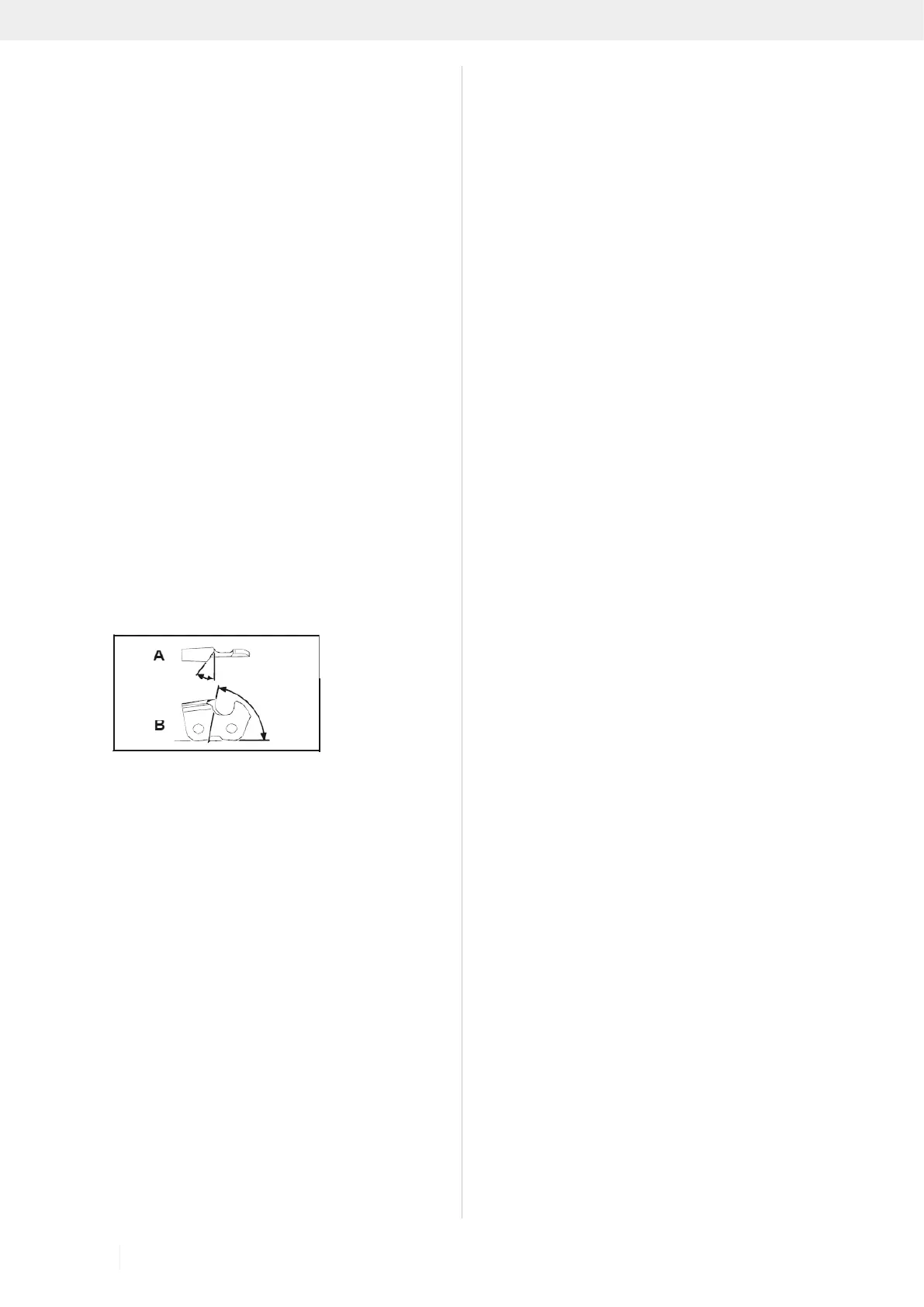

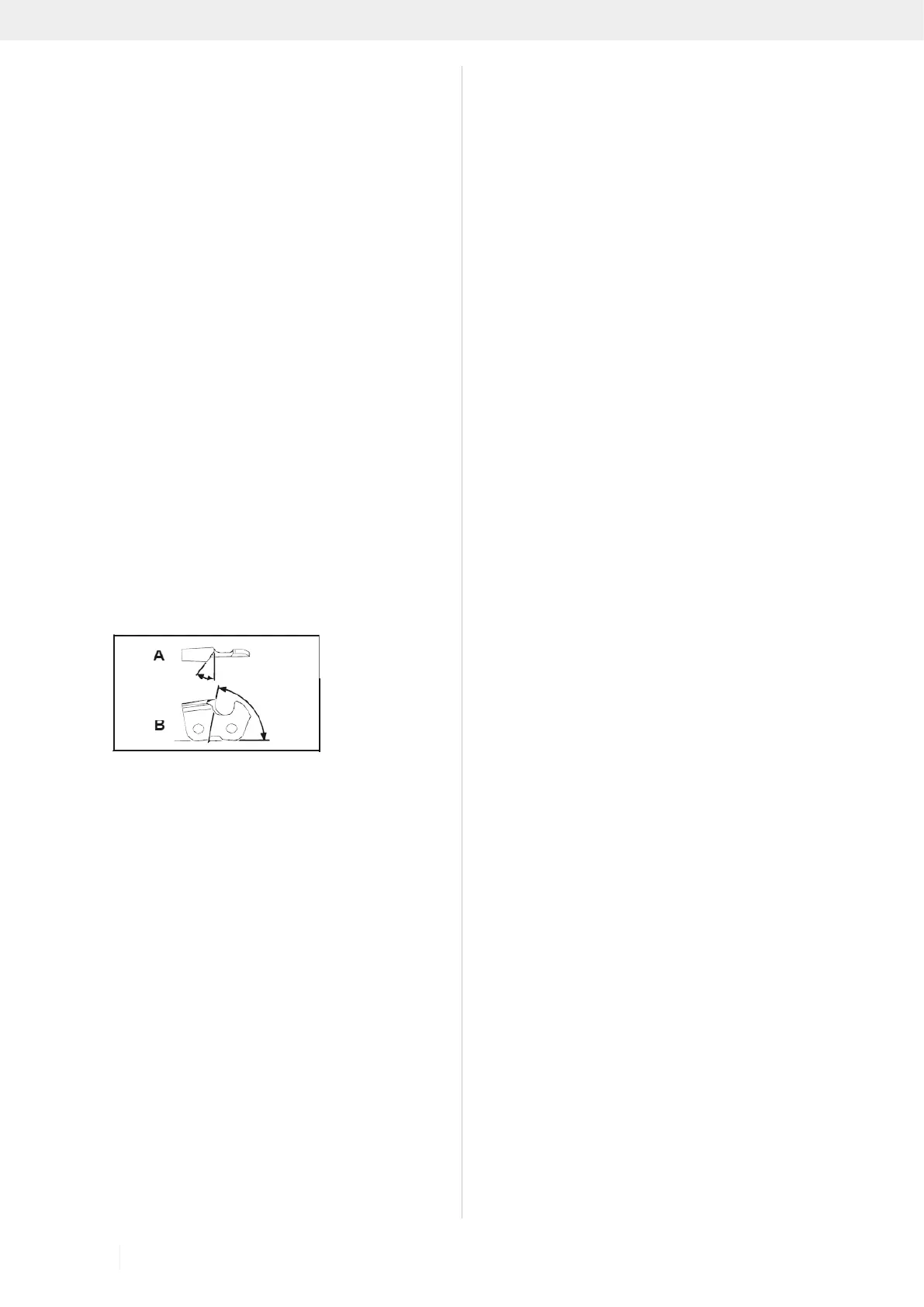

A = ling angle

B = the angle of the side plate

The angle must also be maintained for all knives.

For irregular angles, the chain is run irregularly, wear

quickly and break down prematurely.

Since these requirements can only be met with suf-

cient and regular exercise:

• A File Holder must be used when sharpening the

saw chain by hand. The correct ling angle marked

on it.

• Hold the le horizontally (at a right angle to the

guide rail) and le according to the angle mark on

the le holder. Support the le holder on the top

plate and depth gauge.

• File down. The knife is always from the inside to

the outside

• The le sharpens only in forward motion. Lift it off

in the backward motion.

• Do not touch the dynamic links with the le.

• Turn the le regularly continue to avoid a onesided

wear.

• Remove to remove a piece of hard wood, bones

raw edges.

All knives must have the same length, otherwise they

will also vary. As a result, the chain is irregular and it

increases the risk of going broke.

Lubricate the drive, pole prunner

Lubricate the drive every 10 to 20 operating hours.

1. Apply the grease gun to the grease nipple g .47

(Q).

2. Squeeze some grease into it.

Attention! Fill only a small amount of grease. Do not

overll.

Check the hedge trimmer for obvious faults such

as:

• loose attachments

• worn or damaged components

• bent, broken or damaged cutting tools

• correctly attached and working covers and safety

devices

• wear, in particular, cutting tool play

Immediately replace damaged or blunt cutting

tools, even in the event of minor damage.

Oiling the gears

Oil the gears every 10 to 20 operating hours.

1 Position the grease gun at the lubricating nip-

ples (10).

2 Insert some grease.

Attention! Fill only a small amount of grease. Do not

overll.

Oil the cutting tools and the angle adjustment with

environmentally friendly lubricant.

Setting the idle speed Fig. 50

If the cutting tool is still moving when the device is in

idle, change the idle speed.

1. Let the motor warm up for 3-5 minutes

(not at high speed!).

2. Turn the adjusting screw (S):

clockwise

The idle speed will increase (+)

anticlockwise

The idle speed will decrease ()

The idle speed is 3000 rpm.

Contact the manufacturer if the cutting tool still con-

tinues to move in idle.

Do not continue working with the tool!

The user is responsible for all damages caused

by non-compliance with instructions in this

manual. This also applies to non-authorized

modications of the tool, use of non-authorized

spare parts, accessories, working tools, unre-

lated and not intended use, secondary damages

due to use of faulty components.

Loading...

Loading...