20 GB

Troubleshooting guide

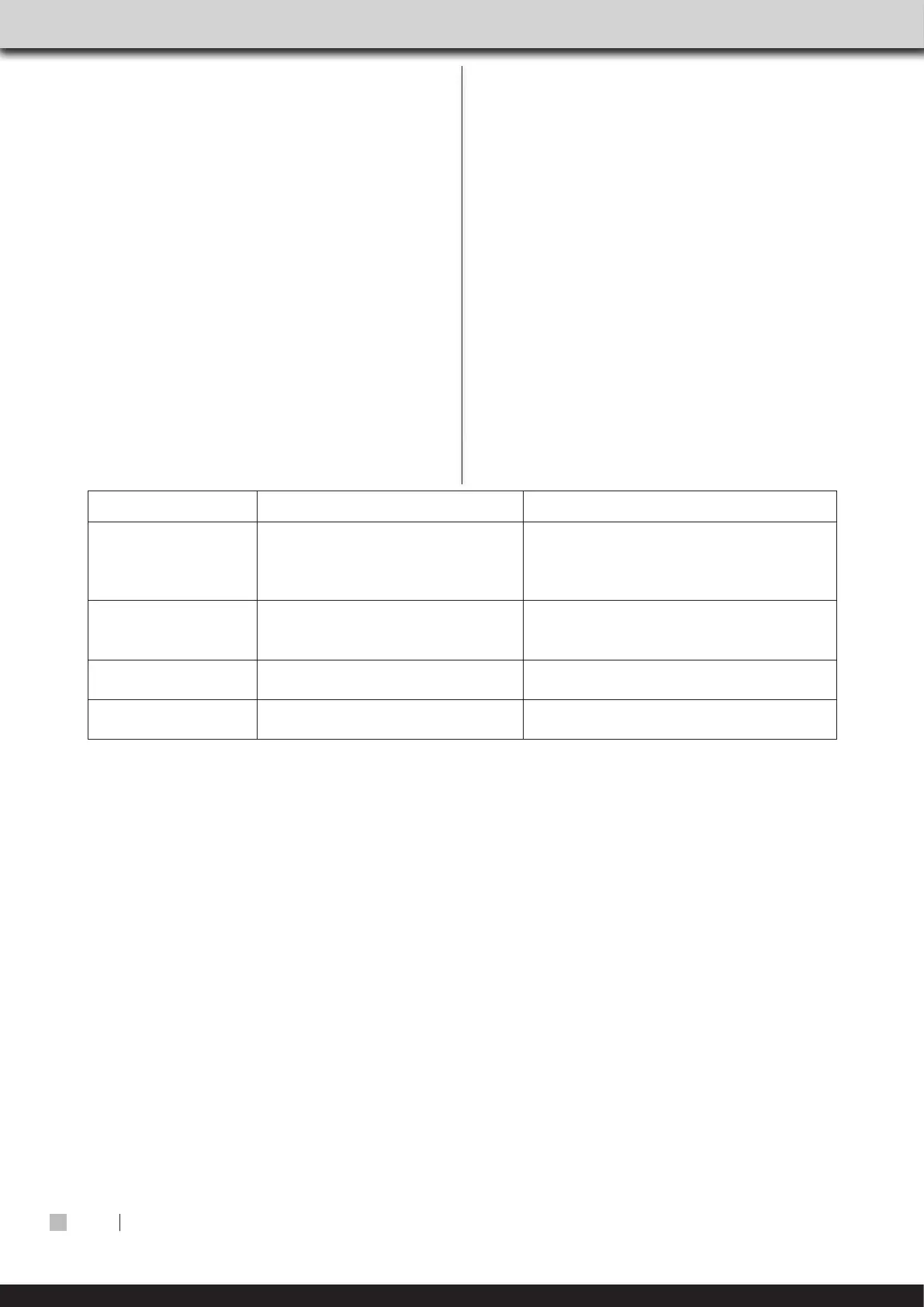

Fault Possible causes Rectication

Motor does not start

a) Engine brake lever not pressed

b) Spark plug defective

c) Fuel tank empty

d) Petrol cock closed

a) Press the engine brake lever

b) Replace spark plug

c) Top up fuel

d) Open petrol cock

Engine performance

drops

a) Soil is too rm

b) Housing clogged

c) Roller badly worn

a) Change working depth

b) Clean housing

c) Replace roller

Imprecise scarifying result a) roller worn

b) Wrong working depth

a) Replace roller

b) Correct working depth

Motor is running, roller is

not rotating

a) Toothed belt is torn a) By customer service workshop

5. Clean the cooling ns of the cylinder and the hous-

ing.

6. Be sure to clean the entire machine to protect the

paint.

7. Store the machine in a well-ventilated place.

Preparing the device for transport

1. Drain the petrol tank using a petrol extraction

pump.

2. Always let the engine run until it has used up the

remainder of petrol in the tank.

3. Empty the engine oil from the warm engine.

4. Remove the spark plug boot from the spark plug.

5. Clean the cooling ns of the cylinder and the hous-

ing.

6. Remove the push bars if necessary. Ensure that

the cables are not kinked.

Disposal and recycling

The equipment is supplied in packaging to prevent it

from being damaged in transit. The raw materials in this

packaging can be reused or recycled. The equipment

and its accessories are made of various types of mate-

rial, such as metal and plastic. Defective components

must be disposed of as special waste. Ask your dealer

or your local council.

Loading...

Loading...