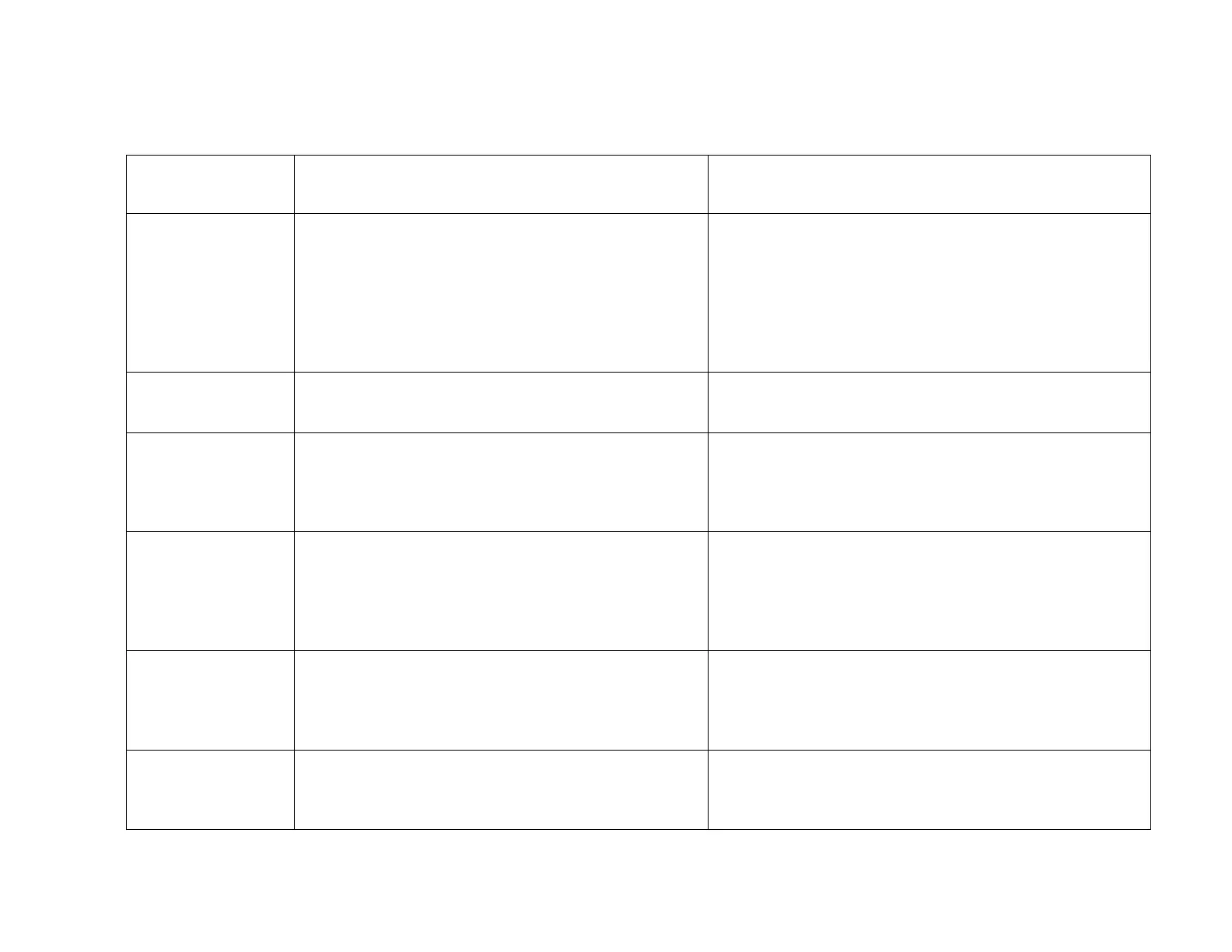

10. Statim 5000 Trouble-shooting – Cycle Faults

Suggested steps for Correction of fault

The cassette temperature failed to reach 95°C

within a time-out period.

This fault may be caused by a large cassette leak in

conjunction with an extremely large load or a blown

thermal fuse caused by weak pump delivery and/or

contaminated steam generator or a faulty steam

generator triac. If the triac has failed, the thermal fuse

may have also failed. A faulty steam generator (steam

generator resistance failed open) could also cause this

fault.

Cycle Fault #2

Software Revisions

R1xx or R2xx only

The cassette temperature failed to increase from

95°C to 100°C within a time-out period.

This may be cause by a major steam leak from the

cassette, incorrect chamber temperature calibration or

an extremely large load.

The cassette has failed to pressurize and achieve a

temperature of 110°C within a time-out period

This may be caused by a faulty cassette seal, a

damaged cassette or faulty solenoid valve (failed to

close). Verify check valve and pressure relief valves for

leaks. For PCB rev other than rev. 7.xx verify Vref to be

2.520V± 0.001V.

The cassette has failed to achieve sterilization

conditions within a timeout period of the chamber

first reaching 110°C.

This may be caused by a faulty cassette seal, a

damaged cassette, improperly installed copper tubing,

a failed or faulty solenoid valve (failed to close) , or

improper alignment of the probe bracket. Verify check

valve and pressure relief valves for leaks. For PCB rev

other than rev. 7.xx verify Vref to be 2.520V± 0.001V.

Cycle Fault #5

Software Revision

R1xx only

The software causes the pump to activate at

predetermined times. If a request to pump water

occurs outside of the predetermined time Cycle

Fault #5 occurs.

This may be caused by a leaky cassette, a kink in the

steam generator inlet tube, a leaking solenoid outlet

valve, a weak pump and a very large load in the

cassette.

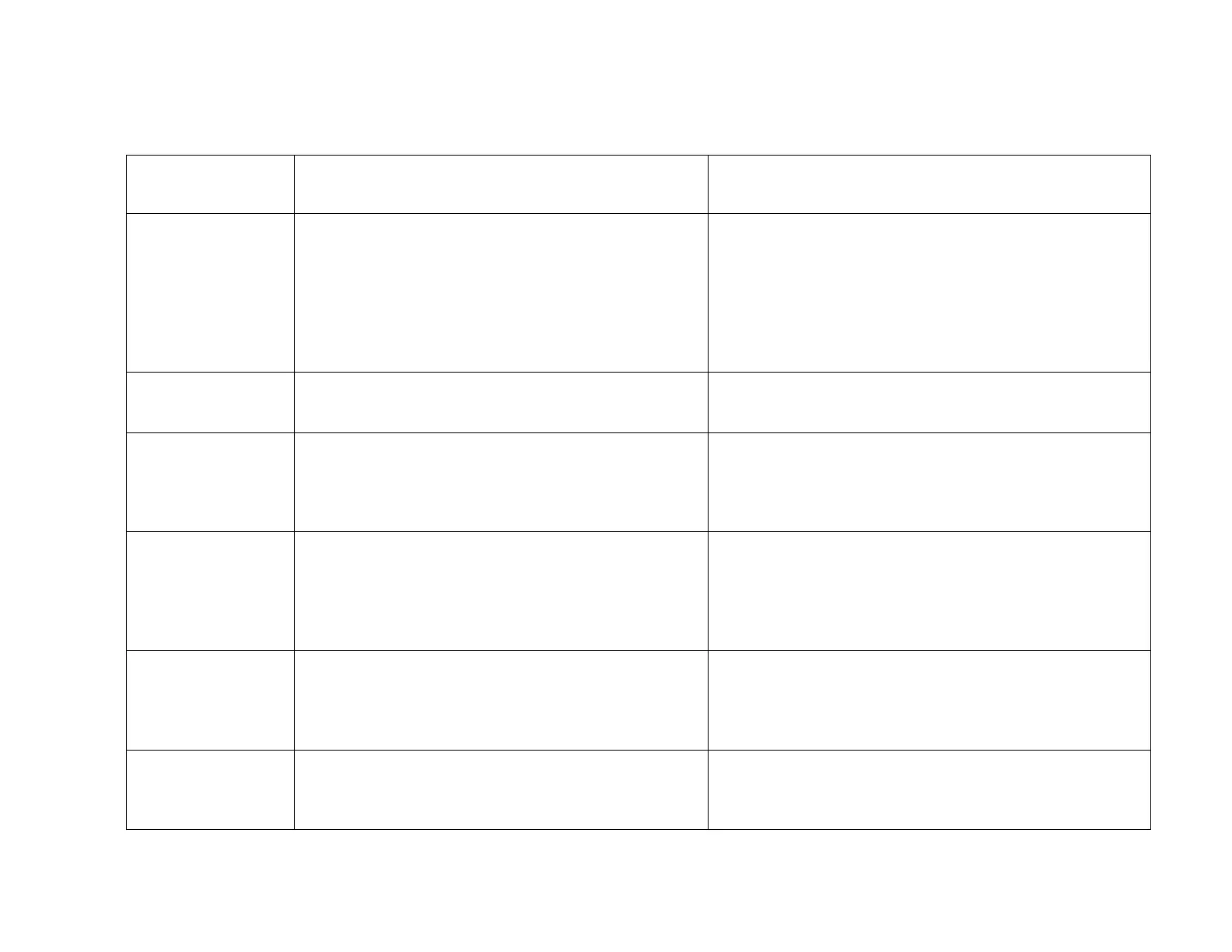

Cycle Fault #6

Software Revisions

R2xx or R4xx

The software has detected the filtered steam

generator temperature 6°C greater than the

chamber during the sterilizing phase of a cycle

The most probable causes are an obstruction caused

by seal misalignment or foreign material in the seal

channel, a need for thermocouple or steam generator

calibration, an old or contaminated steam generator.

Loading...

Loading...