Page 34

Page 34

size of the cubes (Large or Medium) as per the

following setting:

ON ON : PROGRAM A

ON OFF : PROGRAM B

OFF OFF : PROGRAM C

OFF ON : PROGRAM D

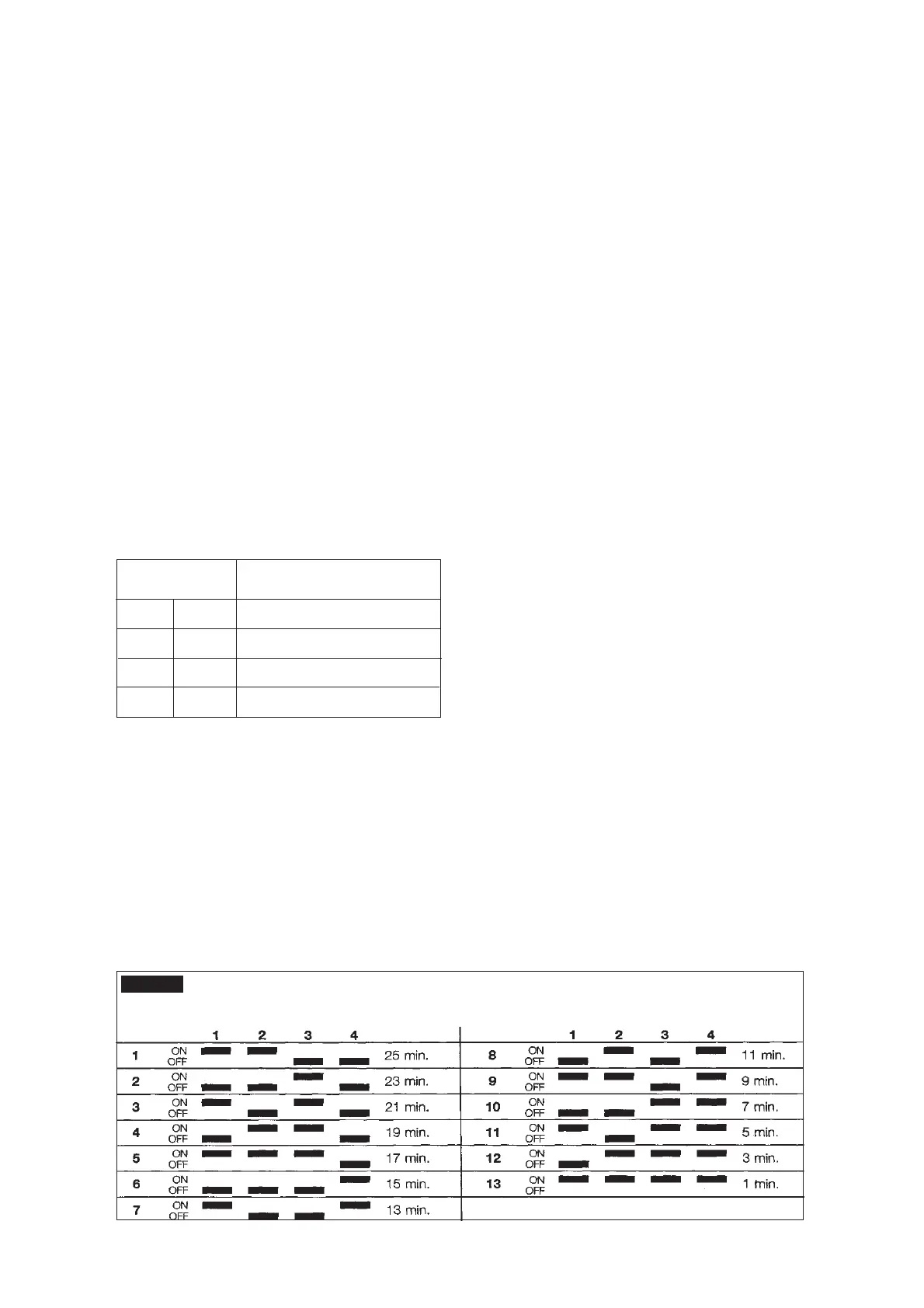

LENGTH OF HARVEST CYCLE

ACCORDING TO THE TIME TO DROP THE

EVAP. TEMPERATURE FROM 0°C TO -15°C

LENGTH PROGRAMS

HARVEST

CYCLE

ABC D

180” Up to 6’30” *** Up to 9’30” xxxx

165” 6’30”-7’ Up to 3’ 9’30”-10’ xxxx

150” 7’-8’ 3’-3’15’ 10’-11’ xxxx

135” 8’-9’ 3’15”-3’30” 11’-12’ xxxx

120” 9’-10’30” 3’30”-4’30” 12’-13’30” < 3'

105” 10’30”-12’ 4’30”-6’ 13’30”-15’ 3' - 4'

90” >12’ >6’ >15’ > 4'

The DIP SWITCH N° 7 and 8 allow the extention

of the length of the harvest/defrost cycle according

to their combination as per following chart:

DIP SWITCH ADDITIONAL DEFROST TIME

78

ON ON 0

OFF ON 30"

ON OFF 60"

With both DIP SWITCH 7 & 8 in OFF position, Water

Pump is OFF during the Harvest Cycle with no additional

time.

The 9th key is used to supply power to the water

pump for the first 15 seconds of the defrost cycle

- position OFF - or for the first 30 seconds -

position ON.

The 10th key is used to modify the CUT-OUT

condensing temperature from 70°C (160°F) for

the air cooled versions - ON position - to 60°C

(140°F) - OFF position - for the water cooled

versions.

L. EXTERNAL SWITCHES SOCKET

Connected to the external Green Master and Red

Alarm Reset Switches, it receives power from the

Master Switch as well as it provides power to the

Red Alarm switch in order to signal any possible

uncorrect operation condition of the machine as

clogged air filter (air cooled version only) or

short/missing of condensing water (water cooled

version) as detailed at item B.

It signal also the time for the cleaning of the water

system of the machine, cleaning that can be

change, according to the local water conditions,

from six month (standard - Jump In) to twelve

months (Jump Out).

Once cleaned the water system, it’s necessary to

cancel the time stored into the PC Board by

pushing and hold for more then 20" the Red

Alarm Re-Set Button till it starts to blink.

M. CONDENSER AIR FILTER

(Air cooled version)

Located in front of the air cooled condenser can

be removed by withdrawing it through the opening

of the front panel for cleaning or replacing. A

lower plastic guide, installed inside the unit, is

used for the correct sliding and location of the air

filter.

N. WATER SPRAY SYSTEM

Through its nozzles, the water pumped, is sprayed

in each individual cup to be frozen into ice.

It consists of one spray tube wheve are located

several spray nozzles.

O. WATER PUMP (2 PCS ECS 126-176)

The water pump operates continually throughout

the freezing cycle and on the first 15 or 30

seconds of the defrost cycle so to such the

remaining water from the sump tank (reach in

mineral salts) and drain it out. During the freezing

cycle the pump primes the water from the sump

to the spray system and through the spray nozzles

sprays it into the inverted cup molds to be frozen

into crystal clear ice cubes. It is recommended

that the pump motor bearings be checked at least

every six months.

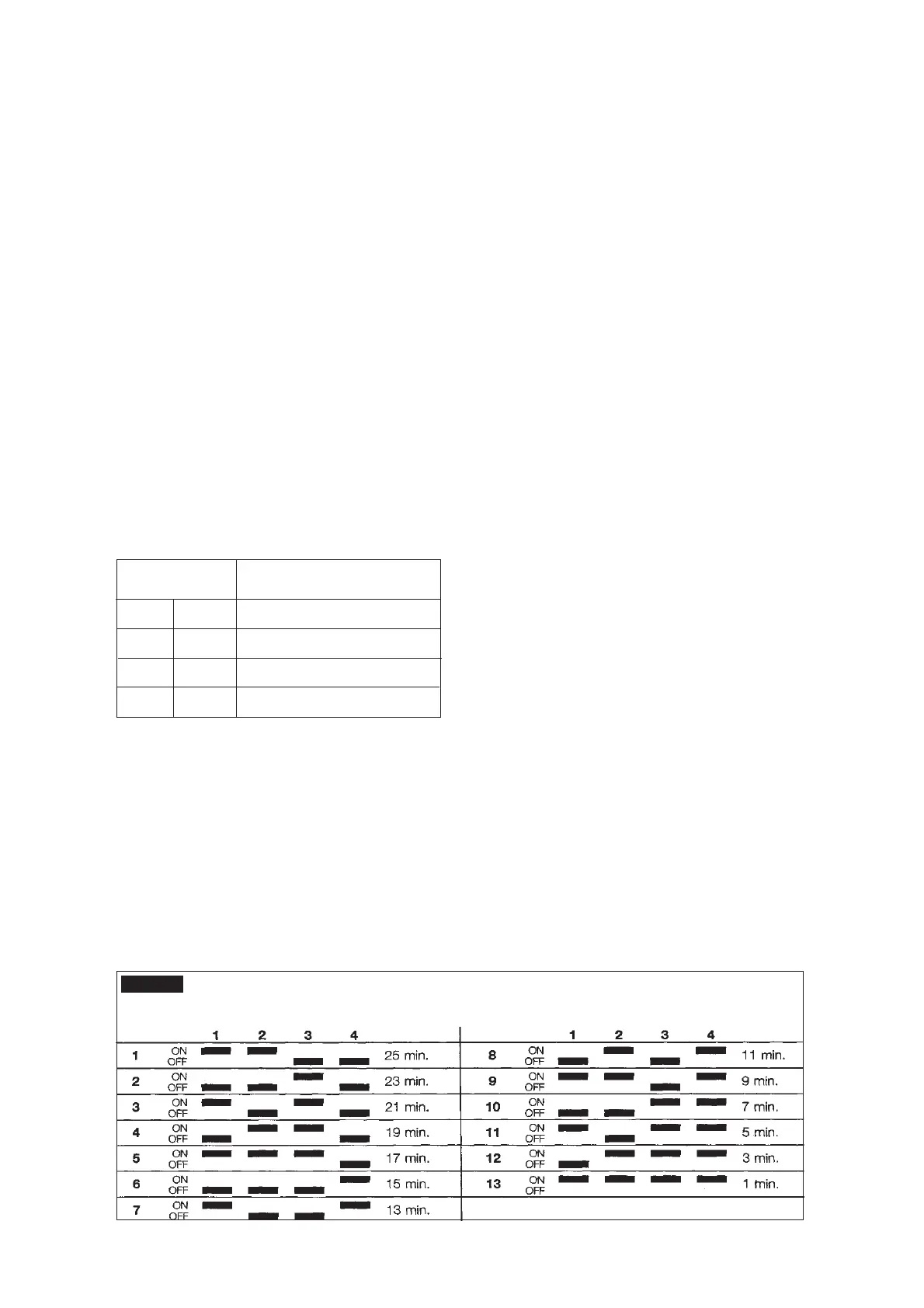

LENGTH OF TIMED PORTION OF FREEZING CYCLE ACCORDING TO THE

DIP SWITCH SETTING COMBINATIONS

TAB. B

Loading...

Loading...