Page 26

Page 26

B. CONDENSER TEMPERATURE SENSOR

The condenser temperature sensor probe,

located within the condenser fins (air cooled

version) or in contact with the tube coil (water

cooled version) detects the condenser tempera-

ture variations and signals them by supplying

current, at low voltage, to the P.C. BOARD.

In the air cooled versions, in relation to the different

current received, the micro processor of the P.C.

BOARD supplies, through a TRIAC, the power at

high voltage to the fan motor so to cool the

condenser and to reduce its temperature. In case

the condenser temperature rises and reaches

70°C (1 60°F) - on air cooled models - or 62°C

(145°F) - on water cooled models - the current

arriving to the micro processor is such to cause an

immediate and total stop of the machine operation.

C. ICE BIN LEVEL LIGHT CONTROL

The electronic ice bin level control, located

into the storage bin, has the function to stop

the operation of the ice machine ONLY AT

THE END OF THE HARVEST CYCLE when

the light beam is interrupted by the ice cubes

stored into the bin.

When the light beam is interrupted the Bin Full

YELLOW LED starts blinking

.

SETTING OF THE ICE LEVEL CONTROL SENSIVITY

In case of any need it's possible to up to date the

sensivity of the optical ice level control as per

here below procedure:

a) Switch OFF the machine at Master Switch

b)Push and hold the PC Board Push Button

c) Switch ON the machine at Master Switch

d) Keep pushed the PC Board Push Button

till the Leds of the PC Board are ON

e) Release the PC Board Push Button.

NOTE. The setting of the Ice Level Control

Sensivity must be done any time a new PC

Board or a new lce Level Control is installed

in the machine.

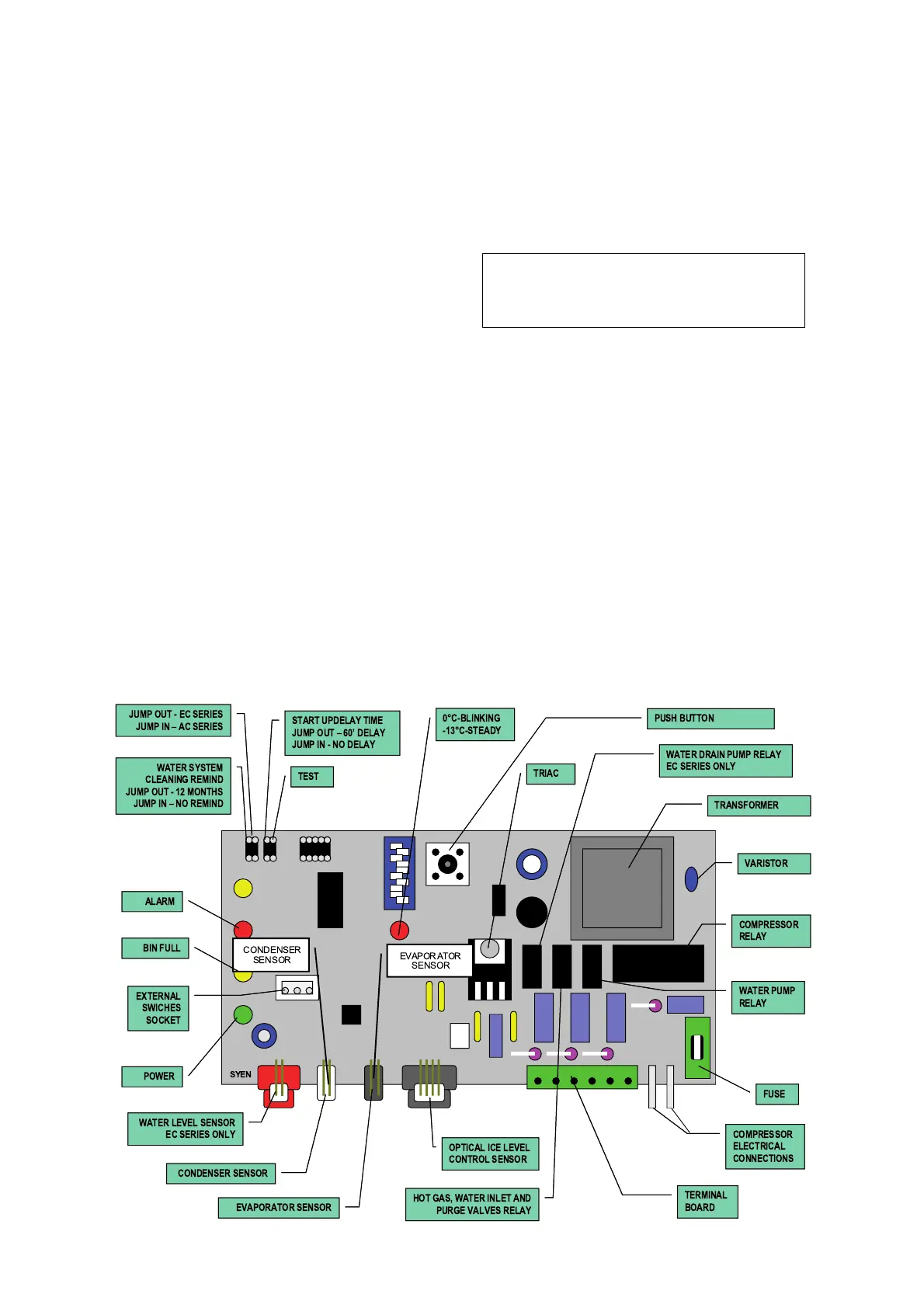

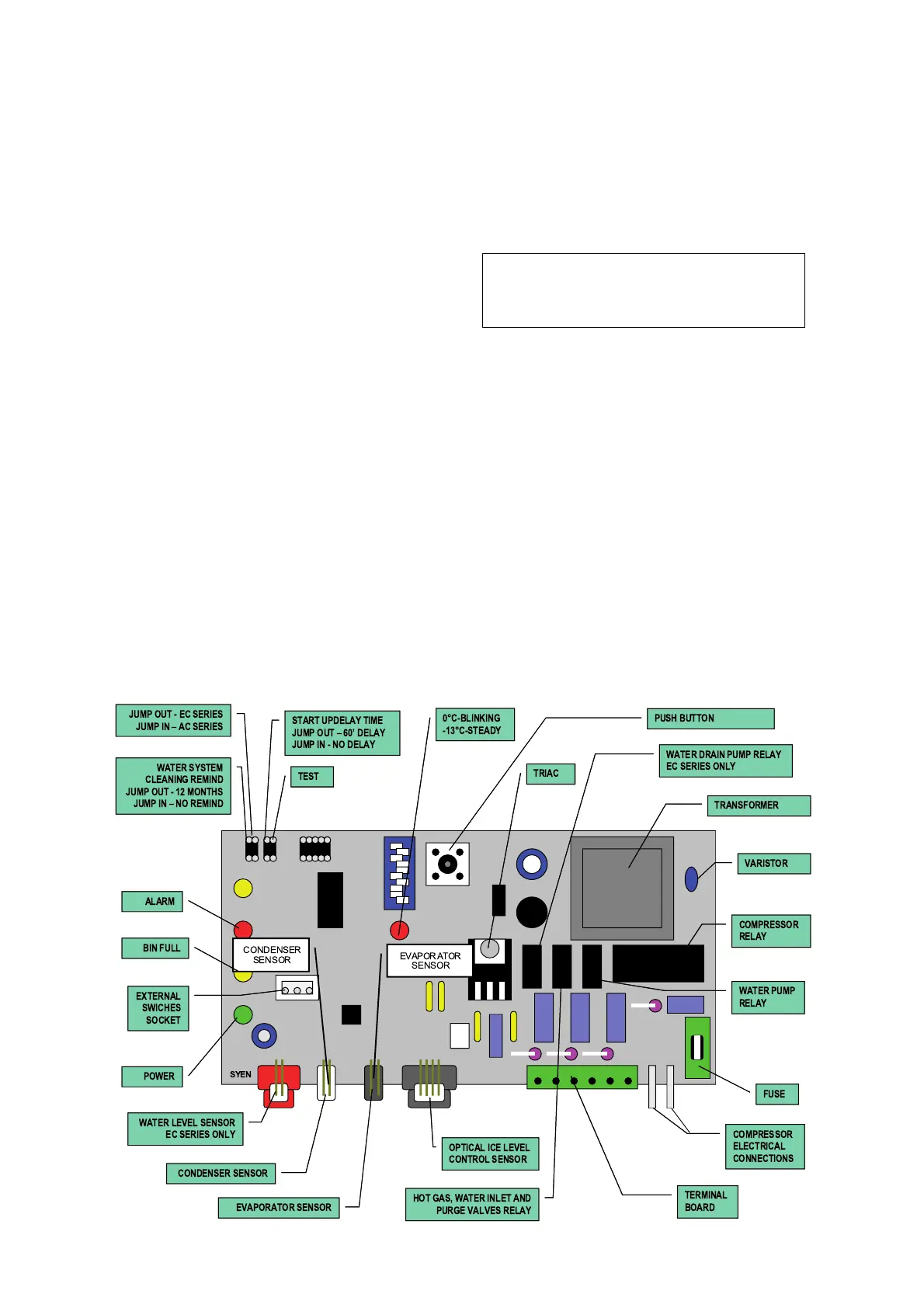

D. P.C. BOARD (Data processor)

The P.C. BOARD, fitted in its plastic box located

in the front of the unit, consists of two separated

printed circuits one at high and the other at low

voltage integrated with fuse on power out (6.3 A),

of four aligned LEDS monitoring the operation of

the machine, of one extra monitoring RED LED

(blink 0°C - steady - 15°C), of one DIP SWITCH

with ten keys, of one push button, of input terminals

for the leads of the sensor probes and input and

output terminals for the leads of the ice maker

electrical wires.

The P.C. BOARD is the brain of the system and

it elaborates, through its micro processor, the

signals received from the three sensors in order

to control the operation of the different electrical

components of the ice maker (compressor, water

pump, solenoid valves, etc.).

SYEN

CONDENSER

SENSOR

EVAPORATOR

SENSOR

PUSH BUTTON

0¡C-BLINKING

-13¡C-STEADY

TERMINAL

BOARD

FUSE

COMPRESSOR

RELAY

TRIAC

TRANSFORMER

VARISTOR

WATER PUMP

RELAY

HOT GAS, WATER INLET AND

PURGE VALVES RELAY

ALARM

BIN FULL

POWER

EVAPORATOR SENSOR

CONDENSER SENSOR

OPTICAL ICE LEVEL

CONTROL SENSOR

WATER LEVEL SENSOR

EC SERIES ONLY

EXTERNAL

SWICHES

SOCKET

COMPRESSOR

ELECTRICAL

CONNECTIONS

WATER DRAIN PUMP RELAY

EC SERIES ONLY

JUMP OUT - EC SERIES

JUMP IN Ð AC SERIES

WATER SYSTEM

CLEANING REMIND

JUMP OUT - 12 MONTHS

JUMP IN Ð NO REMIND

START UPDELAY TIME

JUMP OUT Ð 60Õ DELAY

JUMP IN - NO DELAY

TEST

Loading...

Loading...