scrub your zincs with plastic scrubber or

stainless steel brush to remove the film which

develops. This film will reduce the

effectiveness of your zincs drastically.

! Do not use a brush or scrubber made of

any other metal as it will contaminate your zincs.

! Your downrigger weights should be pure lead, as impurities can produce a

negative charge.

! Use a nylon snap to connect the downrigger cable to the downrigger weight

or use a short piece of monofilament to insulate the weight from the wire.

This breaks a harmful elelctrolysis field which might occur.

! Replace your downrigger cable at least every 2 years if it has been used

often in saltwater, as the galvanic action will etch it over time.

! Do not use zincs on your downrigger wire. This may cause a negative

voltage zone to occur.

Controlling Electrolysis

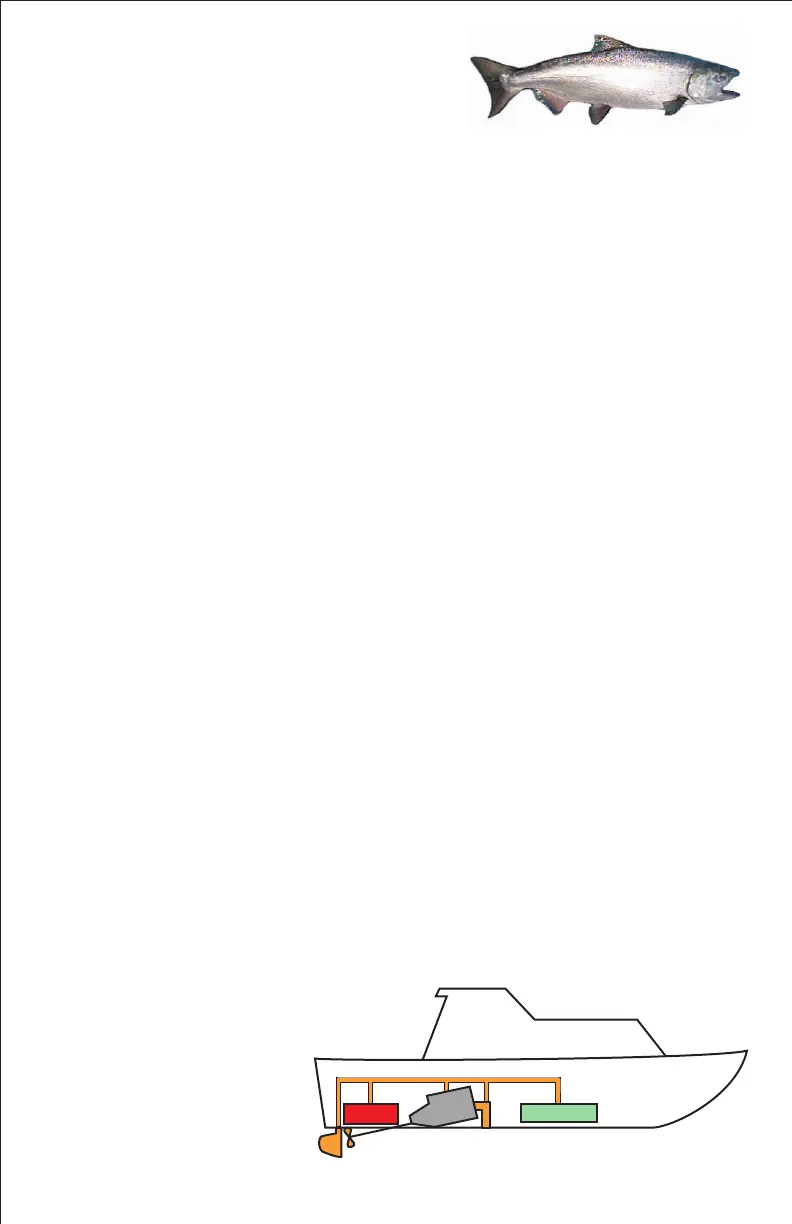

It is important to guard against the effects of electrolysis on your boat. Careful

testing of your boats electrolysis condition will prevent corrosion damage and

perhaps enhance your fishing results. Ideally, your boat should be set up so that

the corrosion is controlled and dissipated in the sacrificial anodes. It is

recommended to measure the levels of electrolysis around your boat to ensure

proper protection. Here's how: Inspect the inside your hull. Look for a copper

bonding wire running along the bottom of the hull, connecting all the underwater

metal fittings-engine, fuel tanks, thru hulls, etc. Check that this wire is unbroken

and has clean, tight connections. Check the connections with a voltmeter, by

touching the positive lead to the fitting and the negative lead to the bonding wire.

The meter should show a reading of .010 volts.

Aluminum boats with an outboard should be properly electrically grounded to the

metal hull or bonding strap. An electric start outboard should also be grounded

(connect the negative terminal of the battery to the boat hull). Also test for

continuity to the boat hull or bonding strap as well as the outboard motor. A #10

bonding wire should be installed from the negative terminal to the hull and to the

outboard if there is no continuity. With the boat in the water, lower a downrigger

wire into the water a few feet. Do this away from marinas or docks to avoid stray

electrical currents. Now test the voltage on your downrigger wire. With your

downrigger weight and wire in the water, turn off everything electrical on your

boat. Turn the master connect battery switches off. Connect the negative lead

from your volt meter to the negative battery terminal, the engine or to one of the

bonded metal fittings on the hull. Connect the positive lead to your downrigger

wire near the spool or along the arm. You should get a natural electrolysis

reading of between .7 and .9 volts. If your reading is much outside this range,

you have a problem. Turn

each of the boat's electrical

systems on one at a time,

starting with the battery

switches, then the bilge

pump, engine and than each

of the other electrical devices.

If your natural electrolysis

voltage reading changes by

Bonding Wire

Water Intake

Rudder & Prop

Fuel Tank

Engine

Battery

Page 3

Loading...

Loading...