SCS - 926 JR Industrial Drive, Sanford, NC 27332

East: (919) 718-0000 | West: (909) 627-9634 • Website: StaticControl.com

TB-9091 Page 4 of 8

© 2019 DESCO INDUSTRIES INC

Employee Owned

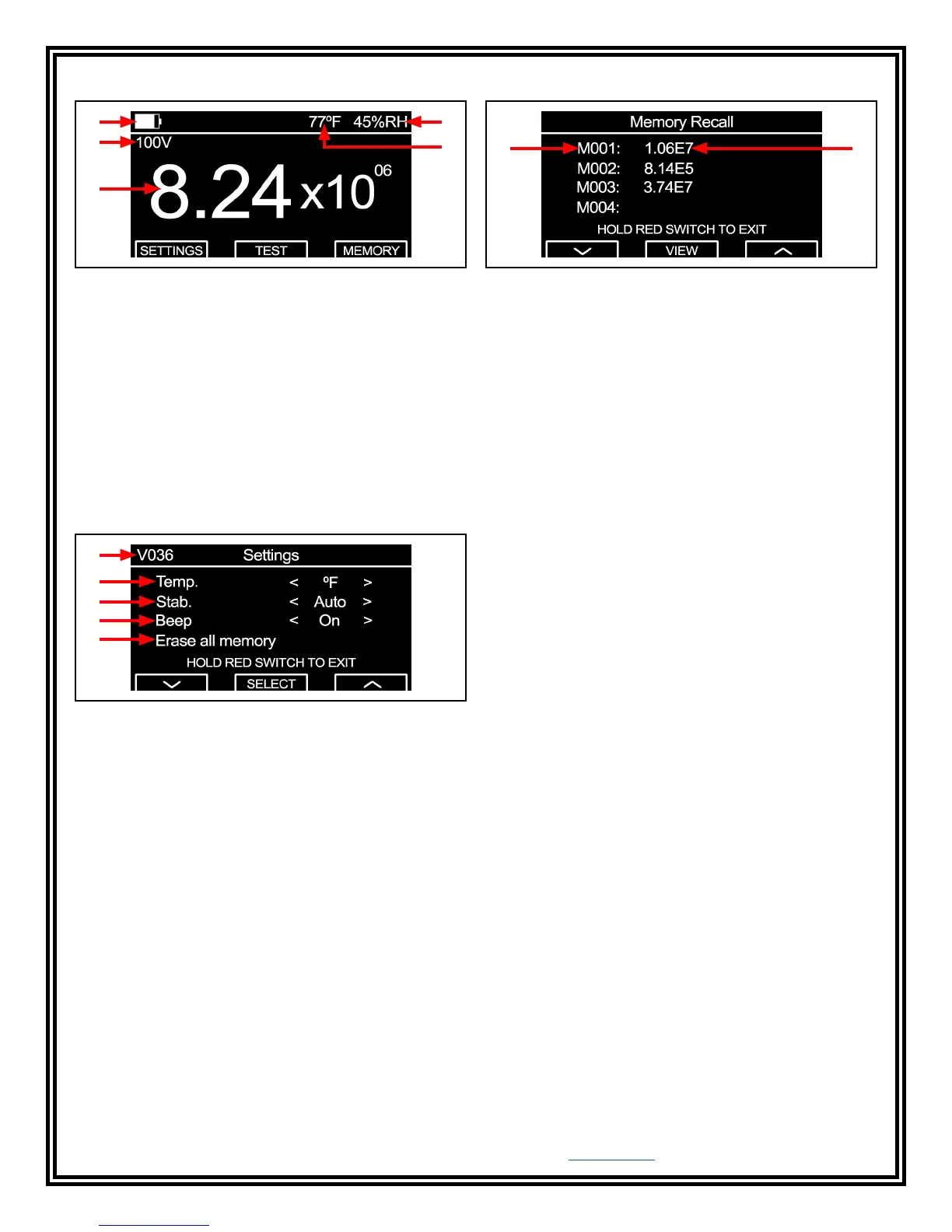

Home / Test Results Screen Memory Recall Menu

H

J

L

I

K

Figure 5. Home / Test Results screen

H. Battery Life Indicator: Displays the approximate life

of the meter's 4 AA alkaline batteries.

I. Relative Humidity: Displays the relative humidity.

J. Test Voltage: Displays the test voltage used to

complete the measurement.

K. Temperature: Displays the ambient temperature.

L. Resistance Measurement: Displays the resistance

measurement in ohms (Ω).

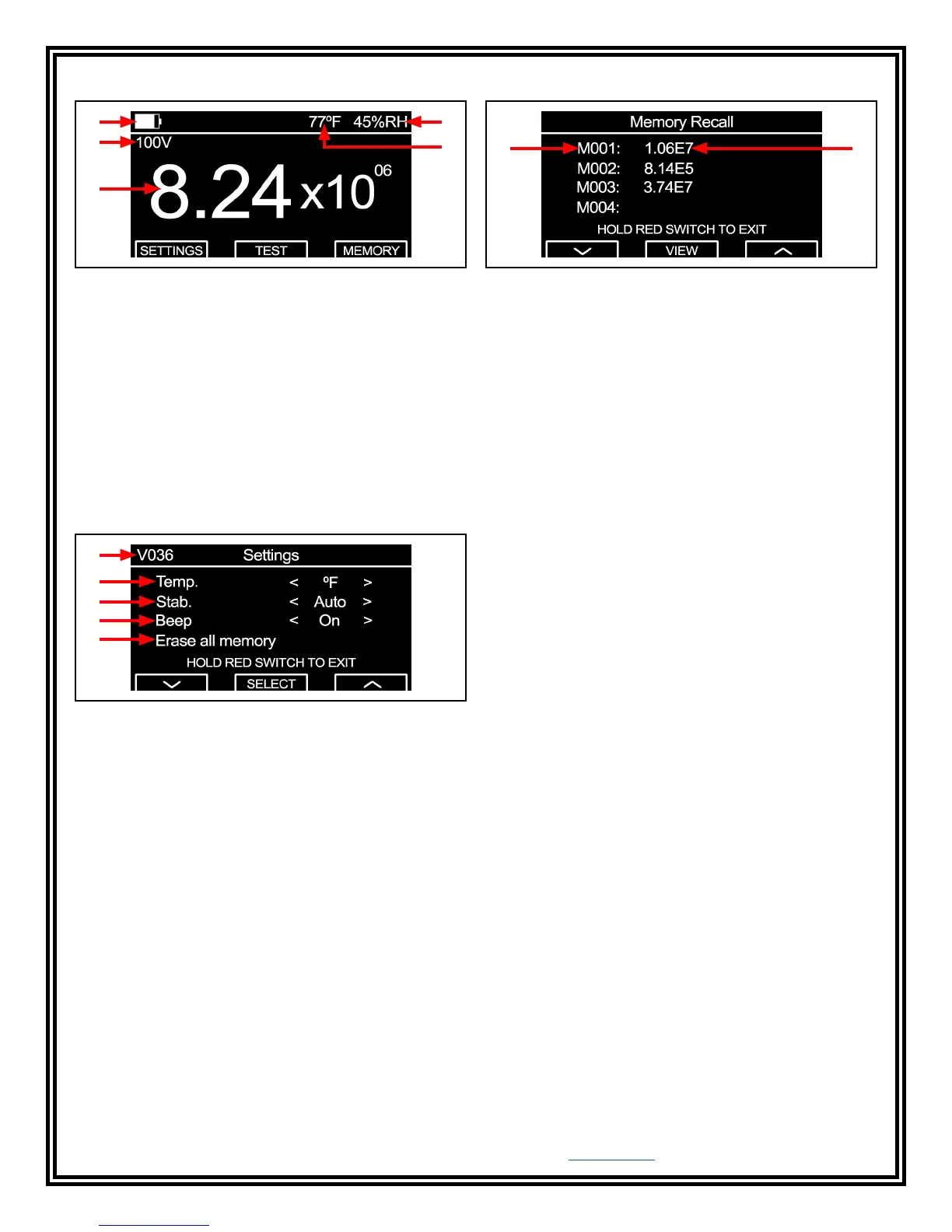

Settings Menu

M

N

Figure 6. Settings menu

M. Firmware Revision: Displays the meter's firmware

revision.

N. Temperature: Sets the unit of measurement for

temperature to either Fahrenheit (ºF) or Celsius (ºC).

O. Stabilization Mode: Sets the meter's electrification

period setting to either Auto and Fixed Stabilization.

Auto - Enables a 15-second electrification period when

the measured resistance is 1 x 10

10

ohms or greater to

maintain test accuracy.

Fixed - Complies with ANSI/ESD S4.1 and enables a

15-second electrification period when the measured

resistance is 1 x 10

6

ohms or greater.

P. Beep: Enables and disables the audible beep when

the meter's pushbuttons are pressed.

Q. Erase all memory: Erases all stored measurement

transactions saved in the meter's memory.

R S

Figure 7. Settings menu

R. Memory Slot Number: Indicates the memory slot

number.

S. Resistance Measurement: Indicates the resistance

measurement value for the respective memory slot.

Operation

General Guidelines

Use both 5-pound electrodes for Resistance

Point-to-Point (Rtt) measurements.

Use one 5-pound electrode, and connect the black

test lead to ground for Resistance-to-Ground (Rtg)

measurements.

Ensure that the item being measured is electrically

isolated (placed on an insulative surface). The meter will

measure the lowest resistance path.

Minimize crossing the test leads when possible.

When using 5-pound electrodes:

• Place them no closer than 2" from the edge of the

surface being measured.

• Place them no closer than 3" to any groundable

point.

• Place them about 10" apart from each other for Rtt

measurements of a worksurface.

• Place them about 3' apart from each other for Rtt

measurement of a floor.

Preferable electrode placements include:

• Most commonly used area of a surface

• Most worn area

• Center of surface

• Furthest area from a grounded point

If the surface to be measured has sections (i.e. floor

tiles, garment panels), place the 5-pound electrodes on

different sections for Rtt measurements.

Clean the material’s surface for test lab measurements,

but do not clean the surface for materials that are

already installed. Only clean and re-test the installed

material if failure occurs.

O

P

Q

Loading...

Loading...