SCS - 926 JR Industrial Drive, Sanford, NC 27332

East: (919) 718-0000 | West: (909) 627-9634 • Website: StaticControl.com

TB-9091 Page 6 of 8

© 2019 DESCO INDUSTRIES INC

Employee Owned

Maintenance

The Resistance Pro Meter requires little maintenance.

There are no user serviceable parts. If the meter

requires service beyond cleaning the electrodes or

replacing the batteries, please contact SCS Customer

Service.

Battery Replacement

Replace the batteries once the battery life indictator

is empty. Open the compartment located on the back

of the meter to replace the batteries. The meter uses

four AA alkaline batteries. Ensure that the batteries’

polarities are oriented in the correct fashion to avoid any

possible circuit damage.

Cleaning the Resistance Pro Meter

The area surrounding the test jacks at the top end of the

meter should be wiped with a clean, isopropanol-alcohol

moistened cloth to remove skin oils that will accumulate

and affect the meter’s accuracy at high resistances.

The frequency of cleaning will depend on usage. SCS

recommends cleaning this area once a month. Cable

jackets should also be cleaned in this fashion.

Cleaning the 5 lbs. Electrodes

Per ANSI/ESD S4.1 “Clean the electrodes with a

minimum 70% isopropanol-water solution. Make sure

the 5 pound electrodes’ conductive pads are dry prior to

use.”

See specific product test standards for test lab

specimen cleaning instructions. Per ANSI/ESD S4.1

Worksurfaces “The test specimens and electrodes

shall be cleaned twice with a minimum 70%

isopropanol-water solution using a clean, low-linting

cloth each time.” (Note: The item should then be

conditioned for 72 hours minimum)

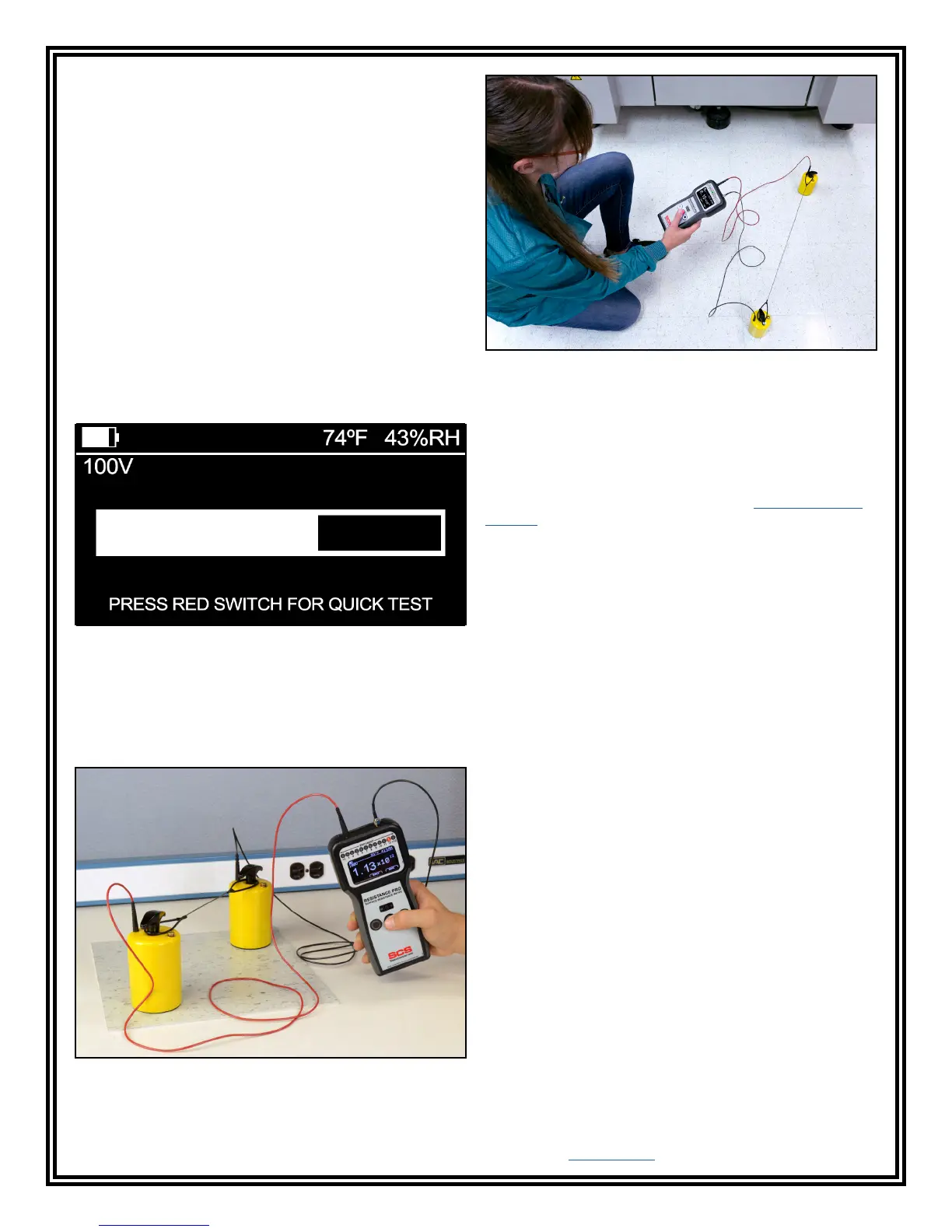

Figure 13. Measuring the Resistance Point-to-Point (Rtt)

of oor materials

Measure Resistance Point-to-Point (Rtt) on the

Surface

1. Do not clean the surface.

2. Remove from the surface only those items that

might interfere with the test. ESD sensitive devices

shall also be removed.

3. Connect both test leads to both 5-pound electrodes,

and place the electrodes on the most commonly

used area of the surface. Use the 10" electrode

spacer to space them 10" apart from each other.

The electrodes should also be 2" away from any

edge and 3" away from any grounded point. If the

most used area is not obvious, use two points near

the center of the surface.

4. Push the red pushbutton to perform a measurement.

Should the 15-second electrification period appear,

it may be bypassed by pushing the red pushbutton

a second time.

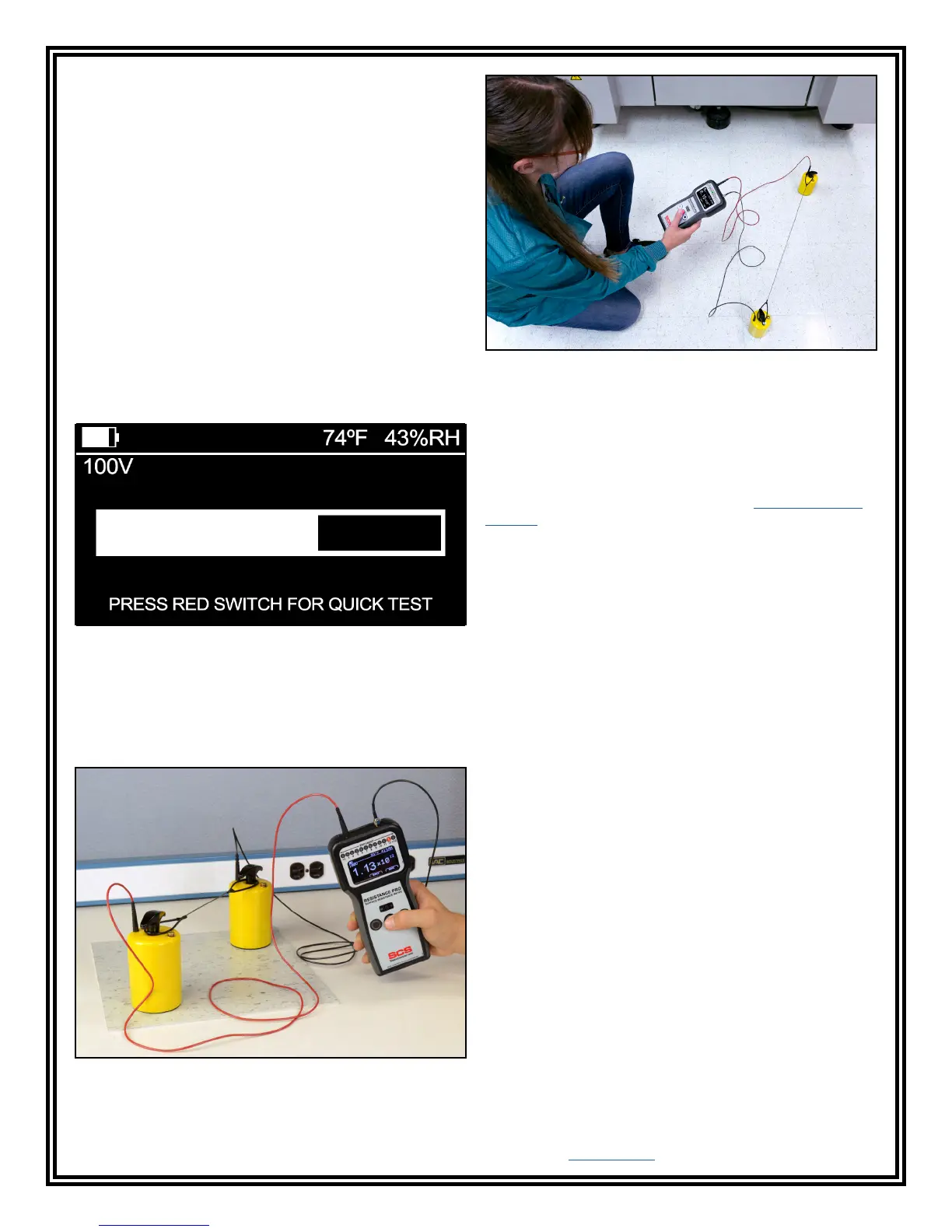

Figure 12. Electrication period timer

5. Push the right black pushbutton to save the

measurement if desired.

6. Perform additional measurements by placing the

electrode on the most commonly used or worn area.

Figure 12. Measuring the Resistance Point-to-Point (Rtt)

of a oor tile

Loading...

Loading...