Scully Signal Company

7

Installation

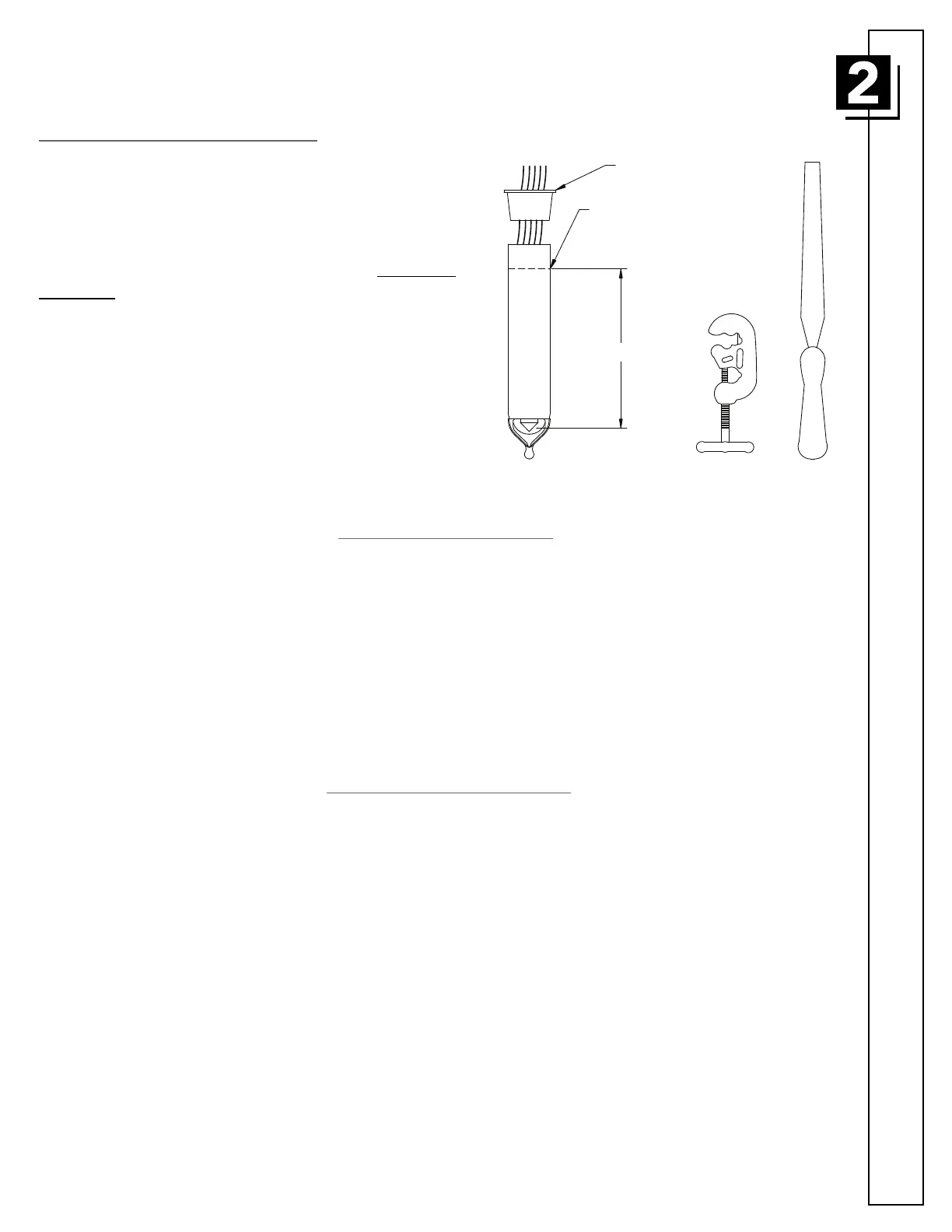

Shortening the Sensor Shaft

The sensor shaft may be shortened to a minimum of

5 1/2” (140mm) when measured as shown.

A three (3) wheel tubing (pipe) cutter is required.

Grasp the sensor shaft in a padded vise. Do not use an

unpadded vise. Crushing the shaft will damage the

sensor and void the warranty. Using the pipe cutter,

trim the shaft length by carefully cutting away the excess

upper part of the shaft.

File the top edge of the shaft, both inside and outside.

Filing the edge will prevent damage to the sensor holder

O-ring. Insert the wire protective cap into the top of the

sensor shaft to prevent damage to the sensor wires.

LEVEL

SENSING

5.50" (140)

POINT

DO NOT CUT

B

ELOW THIS

PROTECTOR

CAP

LEVEL

SENSING

5.50" (140)

POINT

DO NOT CUT

BELOW THIS

PROTECTOR

CAP

SENSOR REPLACEMENT

It should be noted that a sensor can not be repaired. A damaged or faulty sensor (shaft) must be replaced

with an equivalent Scully sensor and may be mounted into the existing holder. The O-ring inside the

holder may incur damage when removing the faulty sensor. The Scully replacement sensor assembly is

supplied with a replacement O-ring for the holder. After removing the faulty sensor from the holder,

remove the old O-ring from the O-ring groove located in the bore of the holder using an O-ring pick or

other suitable tool. Be careful not to damage the O-ring groove. Apply lubricant, either petroleum jelly or

white grease, to the O-ring before installation. Install the new sensor into the holder per the installation

instructions.

ELECTRICAL INSTALLATION

All connections between the sensor leads and vehicle (truck) wiring are to be made inside the sensor

holder. Use appropriate cable glands for strain relief and watertight installation. If conduit is used, its

connections to the holder must be watertight and free from sharp edges. Unused holes must be plugged

with blanking plugs. The sensor features five wires: Black (ground/earth), Red (power), Green (diagnostic),

Yellow (input signal) and Orange (output signal). The connections should be made using crimp connectors

or other permanent means. It is suggested that electrically non-conductive grease is applied to the

connections to further prevent corrosion problems. Leave sufficient wiring length as service loop in each

holder for future maintenance. DO NOT REMOVE (OR CUT OFF) THE LABEL THAT IS ATTACHED TO

ONE OF THE SENSOR WIRES.

Scully recommends the use of our special cable for wiring on a vehicle. If using conduit, 18 AWG (1mm² )

or larger wires should be employed. The SP-FU Sensor should be wired in accordance with the appropriate

Scully Wiring Diagram.

Loading...

Loading...