25

First Run Checklist

Verfiy engine shut down will function correctly.

Must do if you have wired a kill switch to the yellow and gray wires.

Power up the CPi2, but don’t start the engine yet.

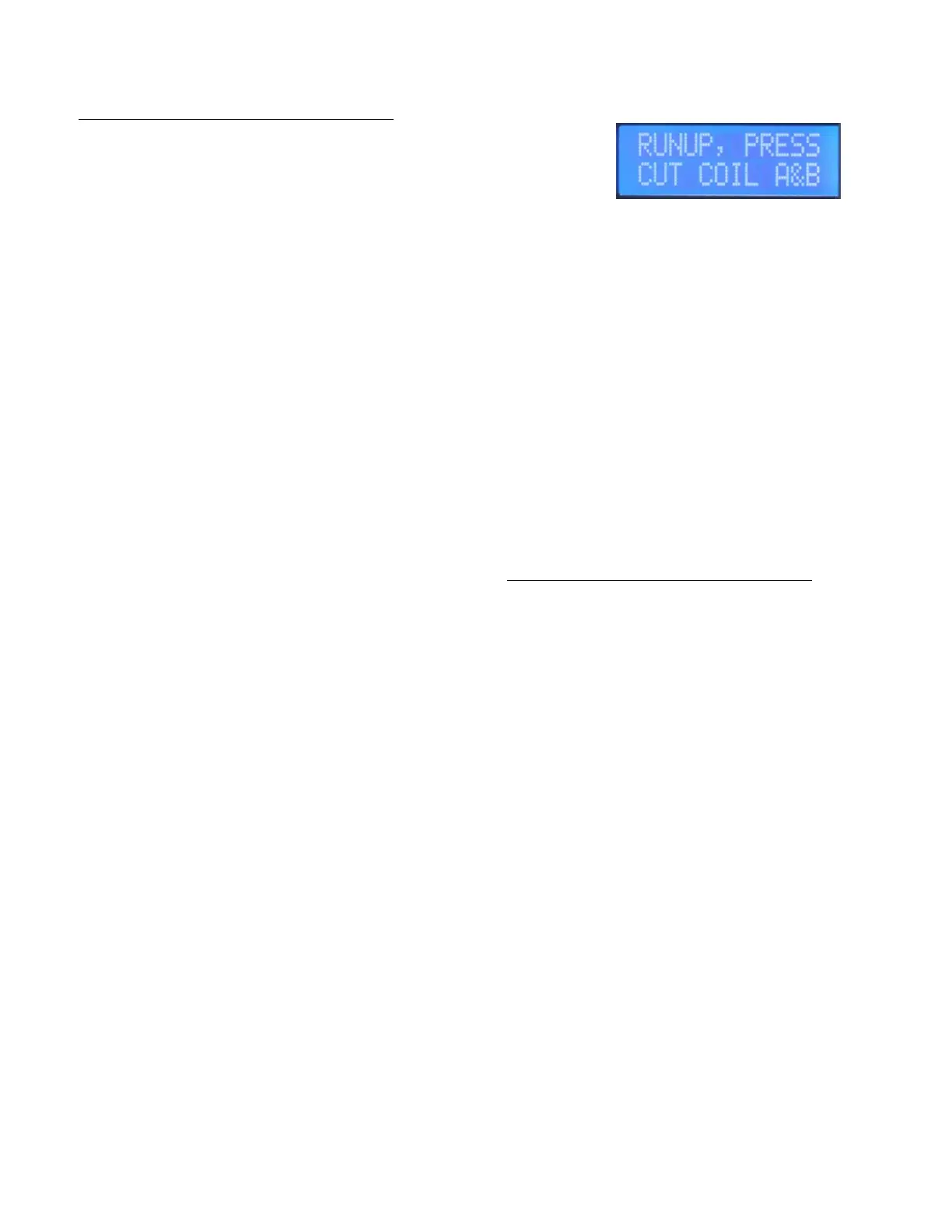

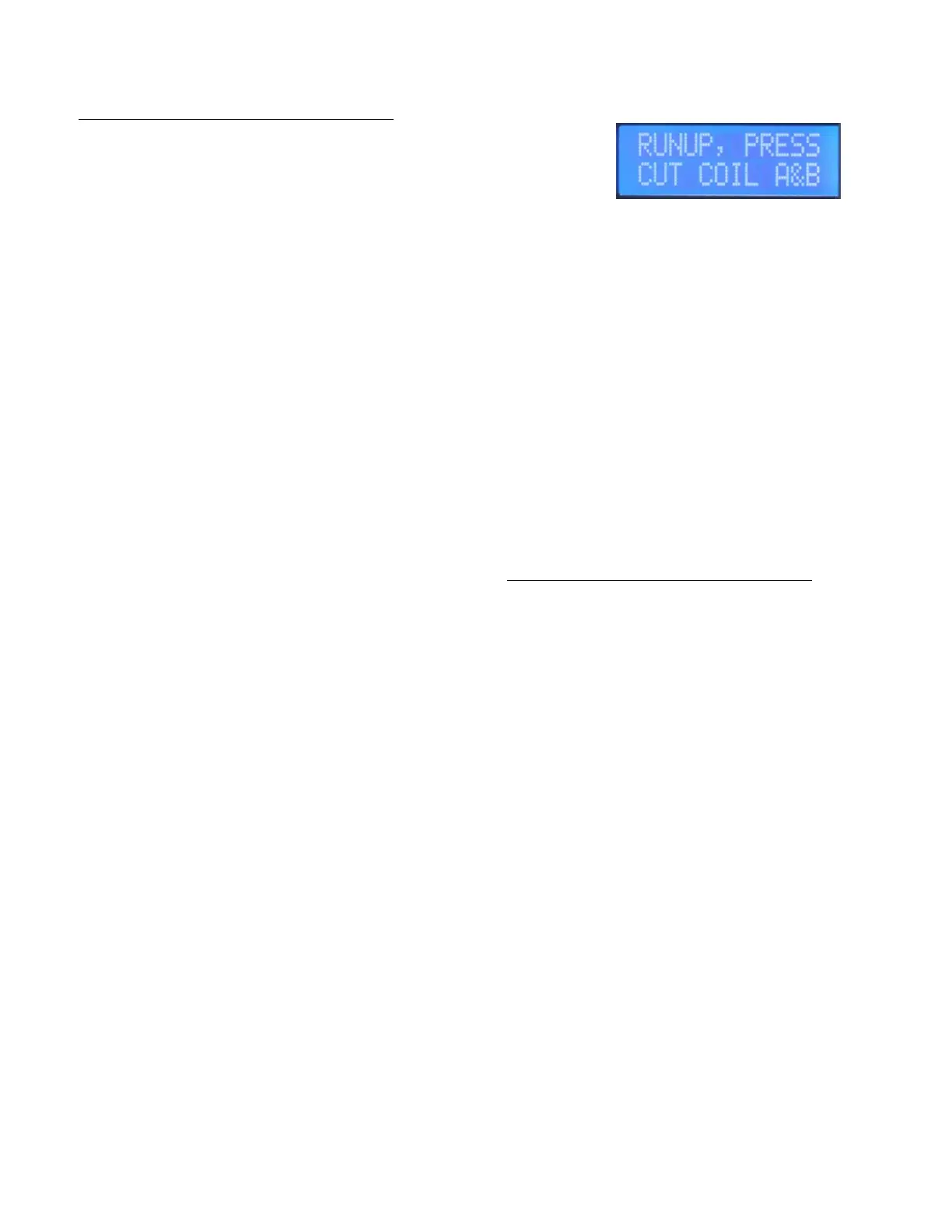

Find the RUNUP screen then activate your kill switch(es) and in the Runup

screen it needs to show CUT COIL A&B like in this photo. If not check

wiring and switch type. If you still have one magneto then you will just have

one kill switch wire, gray, and this screen only needs to show CUT COIL A.

Verify no black wires are unconnected on the 12 and 14 pin harnesses, these need to be grounded. Its possible to

miss a ground wire and the CPi2 still appears to function just fine.

Verify that the Purple wire goes to a low current 12 volt source. Check breaker/fuse rating.

Verify that the Red wire from coil harness goes to a high current 12 volts source. Check breaker/fuse rating.

Verify Spark plug wire resistances are less than 1000 ohms if using MSD red spark plug wire.

Resistor type spark plugs are installed.

Verify plug wires, cylinder numbering, firing order.

Dual Board ecu’s verify hall sensor cables are correct to primary and backup. Green closest to lid red, closest to

flange.

Start the Engine and connect a timing light, read and follow the Magnet Position information and procedure.

On Lycoming and Continental engines we may provide known Magnet Position values if the CNC hall sensor

brackets were shipped with your CPi2 kit. If you did your own hall sensor mount you need to do the Magnet position

procedure with a timing light. Important so timing is calibrated. Uncalibrated timing can destroy your engine.

Once timing is verified you can program specific timing values for your engine. Scroll with the left or right arrows

until you find RPM IGNITION and use plus and minus keys to change the timing in each RPM Ignition window to

whatever is required.

Run engine RPMS as high as possible either tied down or on the brakes.

While running the engine, test other electrical systems in the airplane, things like adjustable prop pitch, and anything

drawing high current or any devices using a solenoid or DC motor to see if these interfere with the CPi2. Inductive

loads may cause electrical noise, so switch these devices on and off many times during your test.

While running the engine test the radio and make some test audio transmissions to see if there is any effect on

engine running, and watch Gauge1 screen and Gauge2(voltage) screens for erroneous readings during radio

transmissions.

Do a high speed taxi test to get RPM’s to maximum possible, this is to test that you don’t blow any breakers or

fuses. Best to do the preflight checklist also especially the Battery Test part of it to prove the backup battery will

perform.

Preflight checklist

1. Press the GAUGE key after powerup.

2. Check voltages MAINBUS BATT Press > once from Gauge1.

3. Start the engine.

4. Runup, Press < once from Gauge1 screen. Do runup test by pressing plus key, wait 5 seconds press minus key.

5. From Runup screen Press < twice.

6. Battery Test, press + key to make the CPi2 run on battery backup power, then press minus key to change back to

mainbus power. Best to rev the engine as high as possible on backup battery to check that your backup battery is

delivering required current.

7. If any RED LED’s are lit don’t fly. See FAULT screen to investigate.

8. Have a printed copy of CPi-2 Fault codes section of this manual. Know how to clear Faults.

Loading...

Loading...