17

Wiring connections are critical to proper ECU function. Make every connection with the

thought that your life depends on each one. It does! Don’t let wires dangle loose which can

lead to eventual breakage. Support them every few inches for least mechanical loading on

them.

Keep wires away from high heat sources and protect them from any possible chafing.

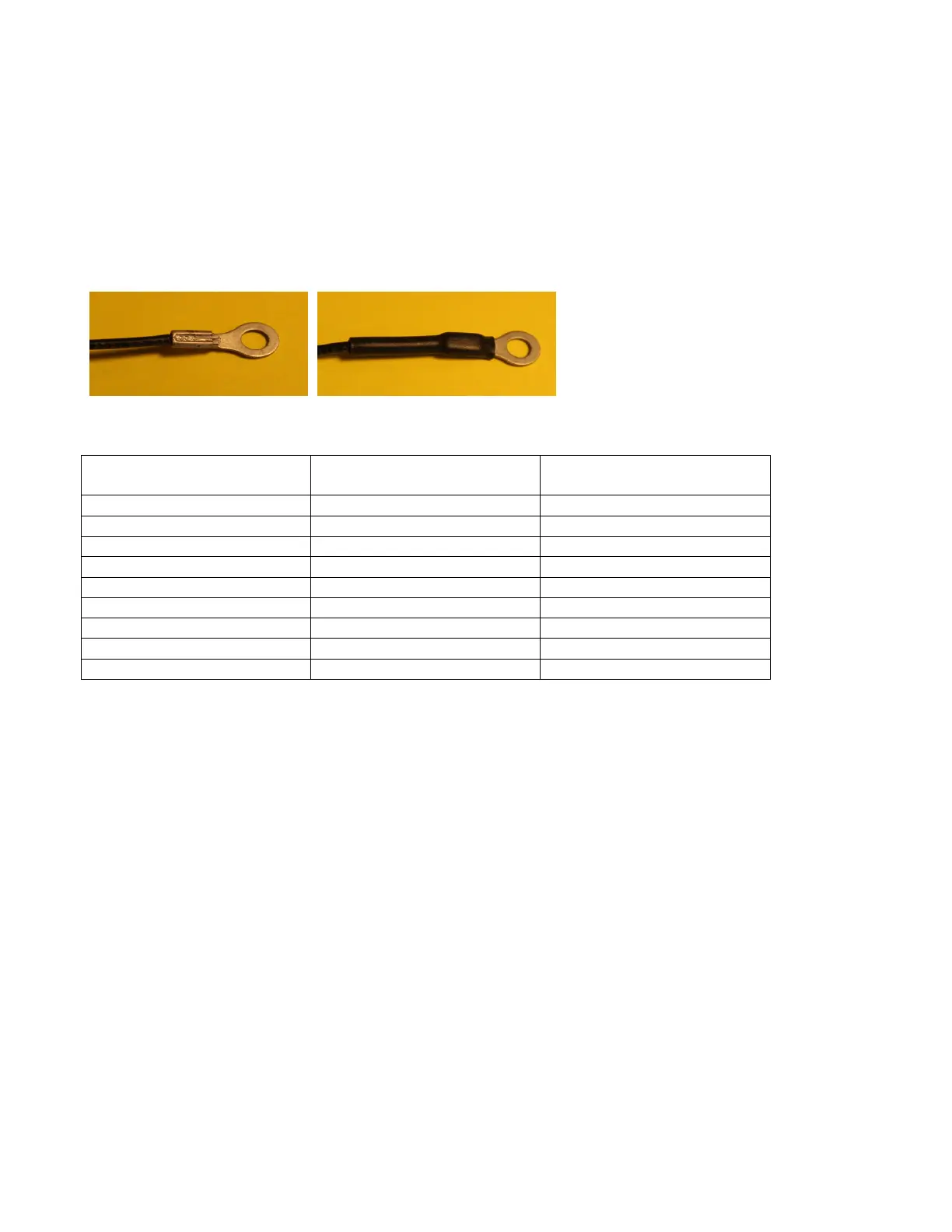

We like to see every individual wire, especially ground and power wires, be properly soldered

or crimped (use the proper crimping tool!) AND a length of heat shrink tubing applied over

connector and about 1 inch down the wire after for strain relief and backup wire retention. See

following photos:

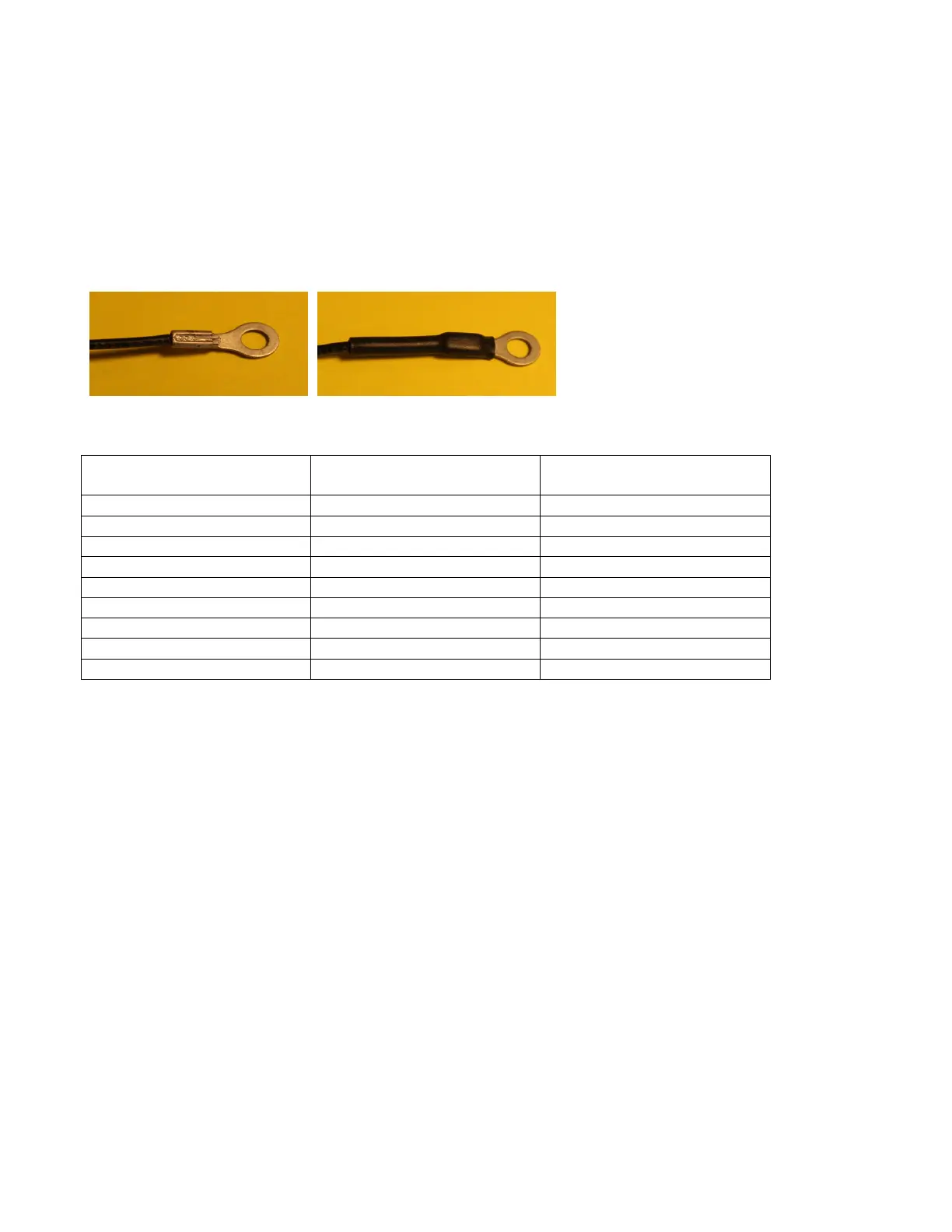

Component Current Draw and Fuse/ Breaker Recommendations

Item Current Draw Range

(Amps)

Recommended Breaker

Size

ECU (each) .03-.13 2

Fuel Pump (each) 4-6 15

Injectors (each ) 2-4 5

Coil Pack 4 cyl. (each) 1-4 10

Coil Pack 6 cyl. (each) 2-6 10

Check Engine Light .1-1 2

Advance Switch Power .1 2

RPM Switch Relay Power .3 2

Fuel Pump Relay Power .3 2

Please note that on some devices such as coil packs and injectors, the current draw varies with rpm.

Backup Electrical Power Considerations

Electrical power is necessary to keep the ECU, fuel pump, coils and injectors running so it’s important

to think about having a backup power source available. In the case of Lycoming engines, a small

backup alternator like the B&C SD8, SD20 or BC410-H SD can be fitted to a vacuum pump pad. On

other engines, a small second alternator could be fitted.

If you don’t have a second alternator, you should have a small backup battery. Sizing would depend

on your typical/ maximum distance between airports. Current draw of the pump, ECU, injectors and

coils would be around 12 to 14 amps. A 12 amp/hour battery should give you a solid 30-40 minutes of

flight time, just running the engine electrics. An 18 amp/hour one, around 1 hour. We want to be able

to sustain at least 10 volts to the electrics.

We’ve found the most reliable, simple and light way to get backup battery power to the engine

electrics is a single 12 to 14 gauge wire running from the backup battery, through a 30 amp ATO fuse,

to a heavy duty switch, to an emergency buss where all the engine electrics can receive power.

Simply charge the backup battery every 30 days and load test annually.

If you have the recommended check engine light fitted, it will warn you any time the battery voltage

falls below 12.5V. You can monitor battery voltage in Gauge 3 mode.

Loading...

Loading...