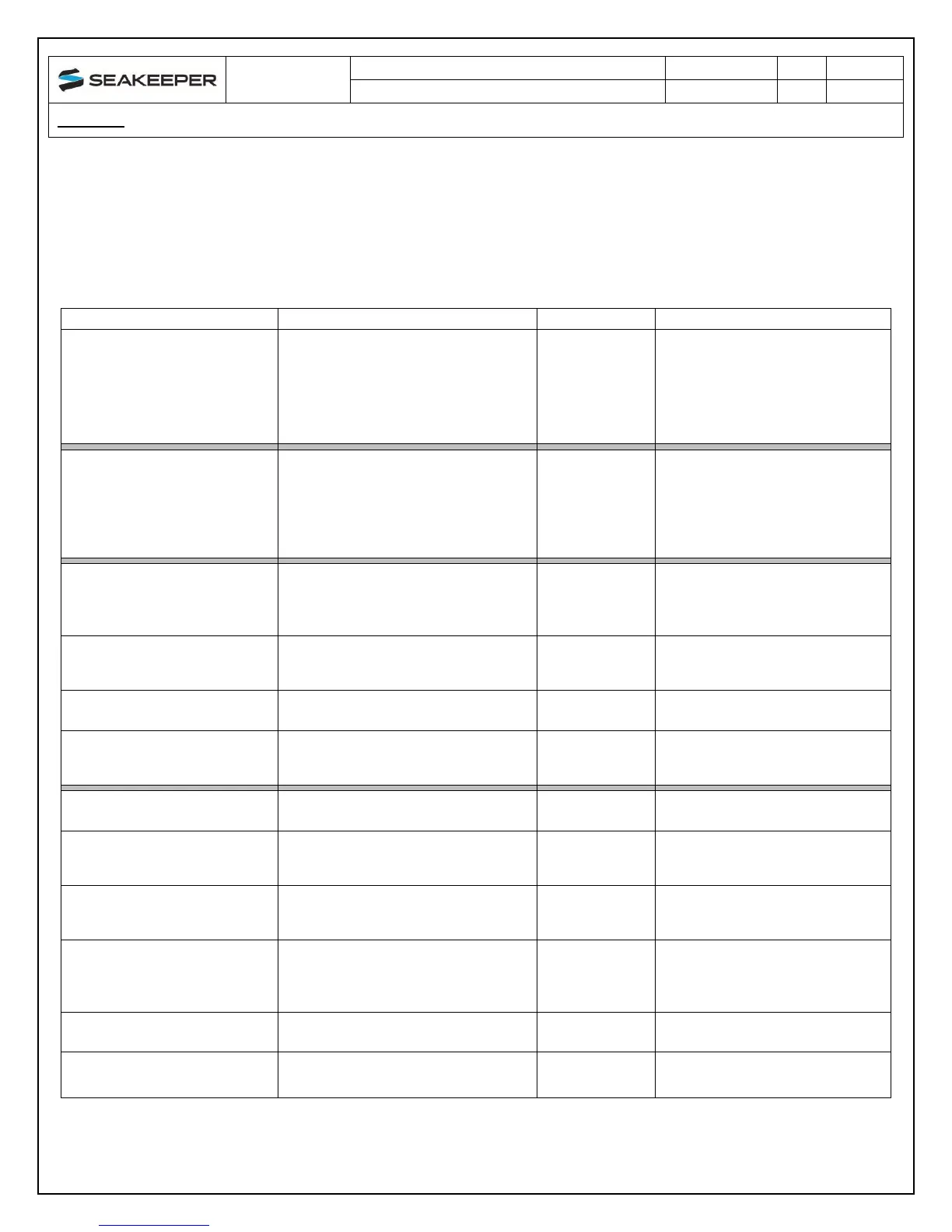

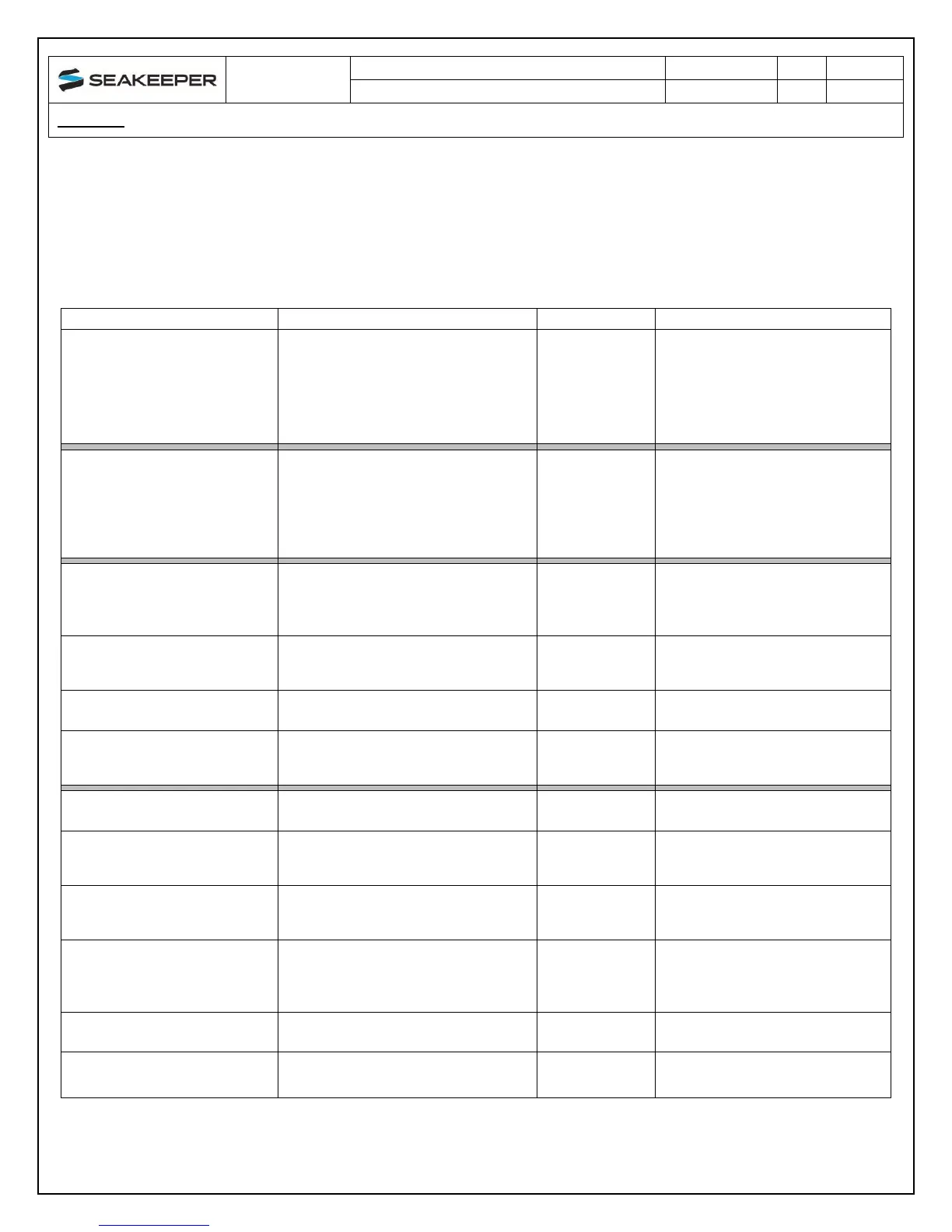

4.4 SCHEDULED MAINTENANCE TABLE

The following pages contain the scheduled maintenance table organized by systems:

Mechanical, Hydraulic, Cooling, and Electrical. Scheduled maintenance is not covered

under warranty.

Inspect unit for severely corroded

areas and clean and touch up with

paint. See Service Bulletin 90026.

Awlgrip Paint Part Numbers:

Top Coat, Snow White: F8063

Top Coat Converter: G3010

Check for cracks or chafing. If

chafing found, reposition hose to

provide clearance around hose. If

chafing is severe, replace hose.

Charge system per Service

Bulletin 90025.

Replace zinc anode as needed.

Note the wear rate after each

check and adjust inspection

interval accordingly.

Replacement Zincs are

available from Seakeeper.

Check for cracks or chafing. If

damaged, replace hose. Fill

cooling system and purge air.

Anti-freeze – 50/50 Ethylene

Glycol mix.

Inspect heat exchanger for signs of

leaks.

Fill with environmentally safe,

marine anti-freeze during winter or

periods of in-operation.

Inspect all connectors for

corrosion, replace if necessary.

Inspect all ground points for

corrosion, clean as necessary, and

treat with corrosion inhibitor.

Electrical / Gimbal Angle

Sensor

Check calibration of sensor. See

Service Bulletin 90083 for

instructions.

Only if Angle

Alarms occur

Check all cables and wire harness

branches for cracks or chafing.

Take special attention to gimbal

shaft areas.

Check for seal at cable glands.

Check integrity of motor power

cable jacket.

Loading...

Loading...