5. MAINTENANCE

N.B. Stop the engine before servicing. Put the engine on a level surface and remove the spark plug cap to prevent engine from

starting.

5.1. The engine must be properly maintained to ensure its operation be safe and economical.

In order to keep the engine in good working condition, it must be periodically serviced. the following maintenance schedule and routine

inspection procedures must be carefully followed:

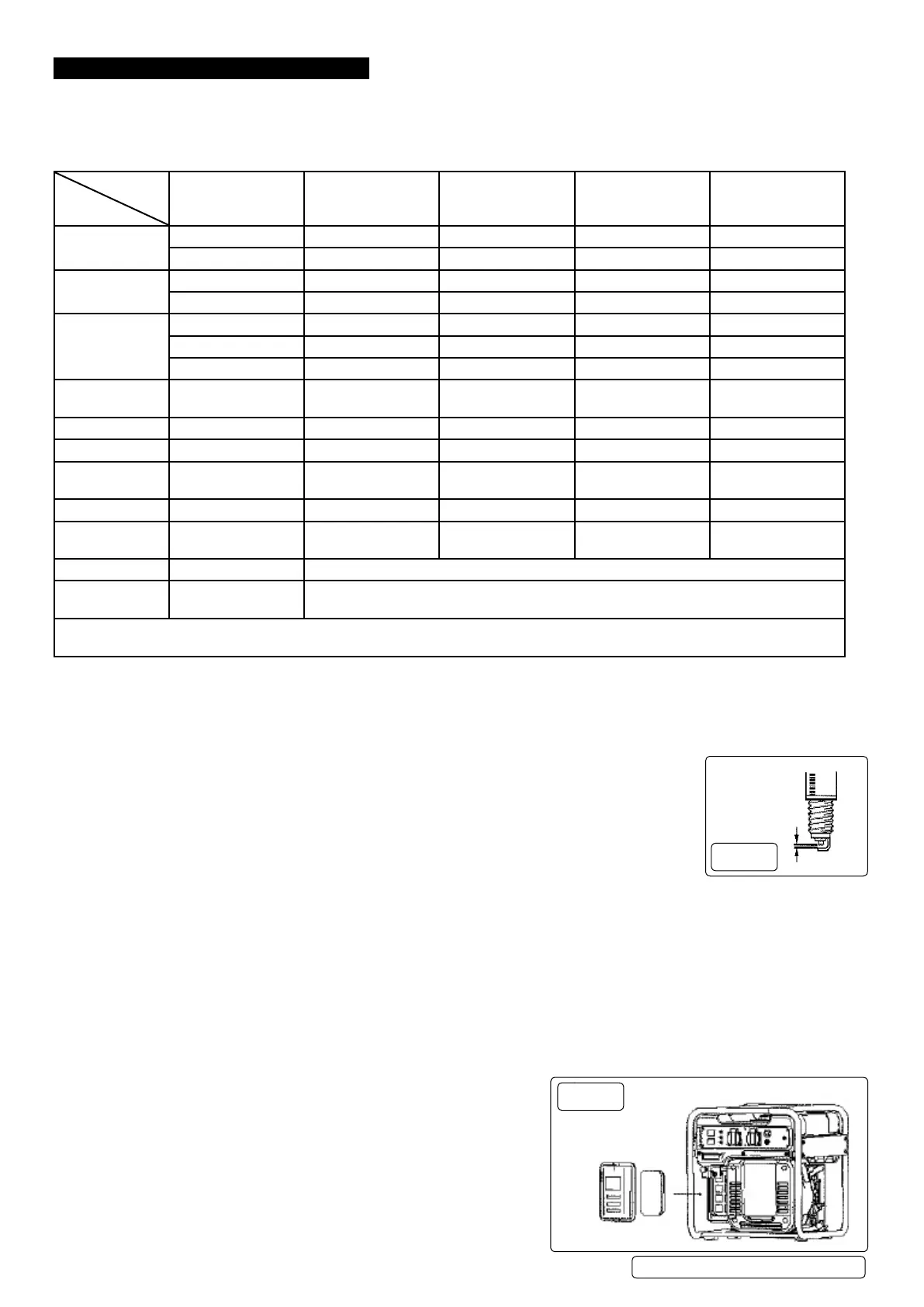

Items

Each Time Firstmonthorrst

20hrs of operation.

Thereafter every

3 months or every

50hrs of operation

Every year or every

100hrs of operation.

Engine Oil Check-Rell

9

Replace

9 9

Reduction gear

Oil (if equipped)

Oil Level Check

9

Replace

9 9

Airlterelements Check

9

Clean

9

Replace

9

Deposit Cup (if

equipped)

Clean

9

Spark Plug Check-adjust

9*

Spark arrester Clean

9

Idling (if

equipped)**

Check-adjust

9

Valve clearance** Check-adjust

9

Fuel tank & fuel

lter**

Clean

9

Fuel Line Check Every 2 years (change if necessary)

Cylinder head

,piston

Clean up carbon <225cc, Every 125hrs

≤225cc,Every250hrs

* These items should be replaced if replacement is need.

**Theinstallationandmajorrepairworkshallbecarriedoutbyspecicallytrainedpersonnel.

5.2. If the engine frequently works under high temperature or heavy load, change the oil every 25 hours.

5.3. Iftheengineworksinadustyorotherenvironmentcleantheairlterelementevery10hrs,ifnecessary,changetheairlter.

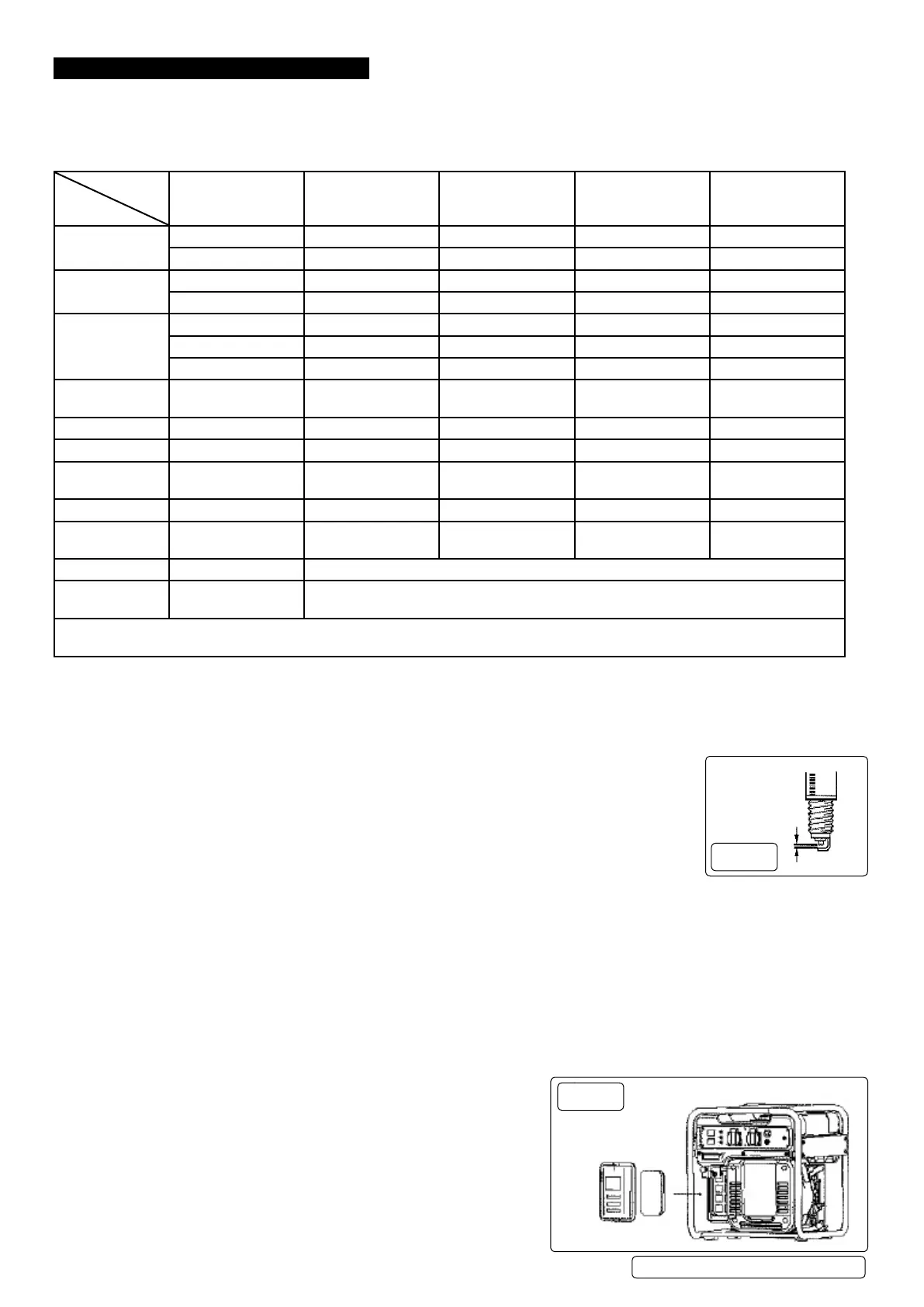

5.4. Spark plug inspection g.16.

5.4.1. Remove the cap and spark plug cap, insert the tool through the hole from the outside of the cover.

5.4.2. Insert the bar into the tool and turn it anti-clockwise to remove the spark plug.

5.4.3. Check for discolouration and remove the carbon. The porcelain insulator around the centre electrode of

the spark plug should be a medium-to-light tan colour.

5.4.4. Check the spark plug type and gap. adjust as required.

Standard Spark Plug: E6TC/E6RTC.

Spark Plug Gap:0.6-0.7mm

Spark Plug Torque: 20Nm

5.5. Carburettor adjustment

Adjustment should be left to authorized stockist with knowledge, data and equipment.

5.6. Engine oil replacement

Do Not drain the engine oil immediately after stopping the engine, the oil will be hot and should be handled with care.

5.6.1. Place the generator on a level surface and warm up the engine for several minutes. Stop the engine and turn off fuel switch knob.

5.6.2. Removetheoilllercap.

5.6.3. Place an oil pan under the engine. Tilt the generator to drain the oil.

5.6.4. Putthegeneratoronaatsurface.

5.6.5. Add engine oil to the top limit level.

Recommendedengineoil:SAESJ15W-40

Recommended engine oil grade: API Service SE type or higher

Engine oil quantity: 0.35L

5.6.6. Wipe away any spilled oil, be sure no foreign material enters the crankcase

5.6.7. Installtheoilllercap/cover

5.7. Air Filter

5.7.1. Removetheairltercover.

5.7.2. Remove the foam element.

5.7.3. Wash the foam element in solvent and dry it.

5.7.4. Oil the foam element and squeeze out excess oil.

5.7.5. The foam element should be wet but not dripping.

5.7.6. Insertthefoamelementintotheairltercase.

5.7.7. Installtheairltercasecoverinpositionandtightenscrews.

g.16

g.17

GI2300,GI3500|Issue1g119/04/18

Original Language Version

© Jack Sealey Limited

Loading...

Loading...