WARNING! If you are not able to split the log, this means that its hardness exceeds the capacity of the machine and thus that log

should be discarded to protect the log splitter.

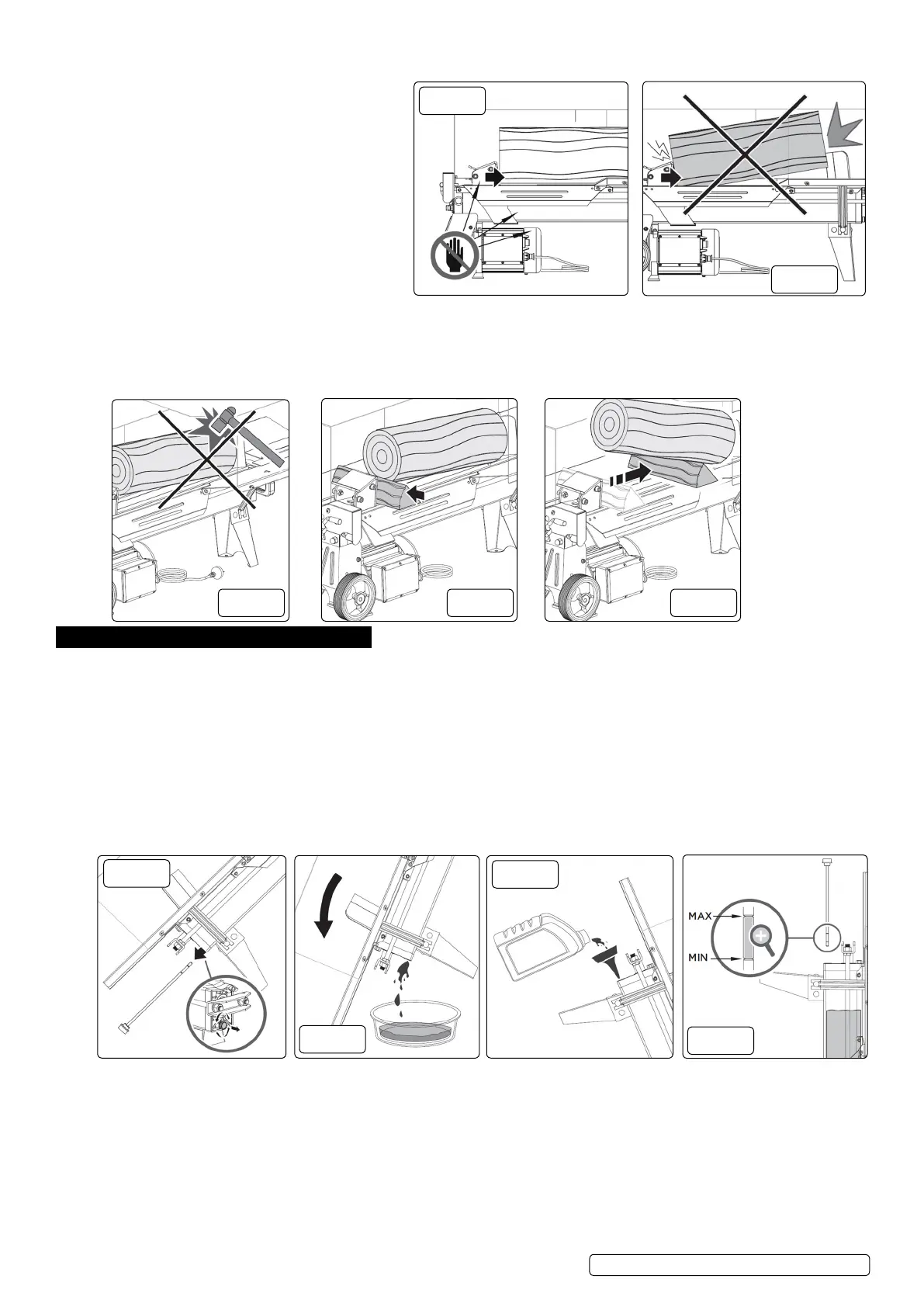

8 DO NOT force the blade by splitting the log on

the upper part. This will break the blade or

damage the machine (g.16).

9 Break log in the direction of its growing grain.

8 DO NOT place log across the log splitter for

splitting. It may be dangerous and may seriously

damage the machine.

8 DO NOT attempt to split 2 pieces of log at the same

time. One of them may y up and hit you.

▲ DANGER! Keep your hands away from splitting

area, live area and heating area while working!

(g.15).

5.3. FREEING A JAMMED LOG (FIG.17)

8 DO NOT try to knock the jammed log off. Knocking about will damage the machine or may launch the log and cause an accident.

5.3.1. Release both controls.

5.3.2. After the log pusher moves back and completely stops at its starting position, insert a wedge wood under the jammed log (g.18).

5.3.3. Start the log splitter to push the wedge wood to go completely under the jammed one (g.19).

5.3.4. Repeat above procedure with sharper slope wedge woods until the log is completely freed.

6. MAINTENANCE

6.1. REPLACING HYDRAULIC OIL

Replace the Hydraulic oil in the log splitter after every 150 hours of use with a good quality oil such as Sealey HJO5LS. Take the

following steps to replace it.

WARNING! Make sure all moving parts stop and the log splitter is unplugged.

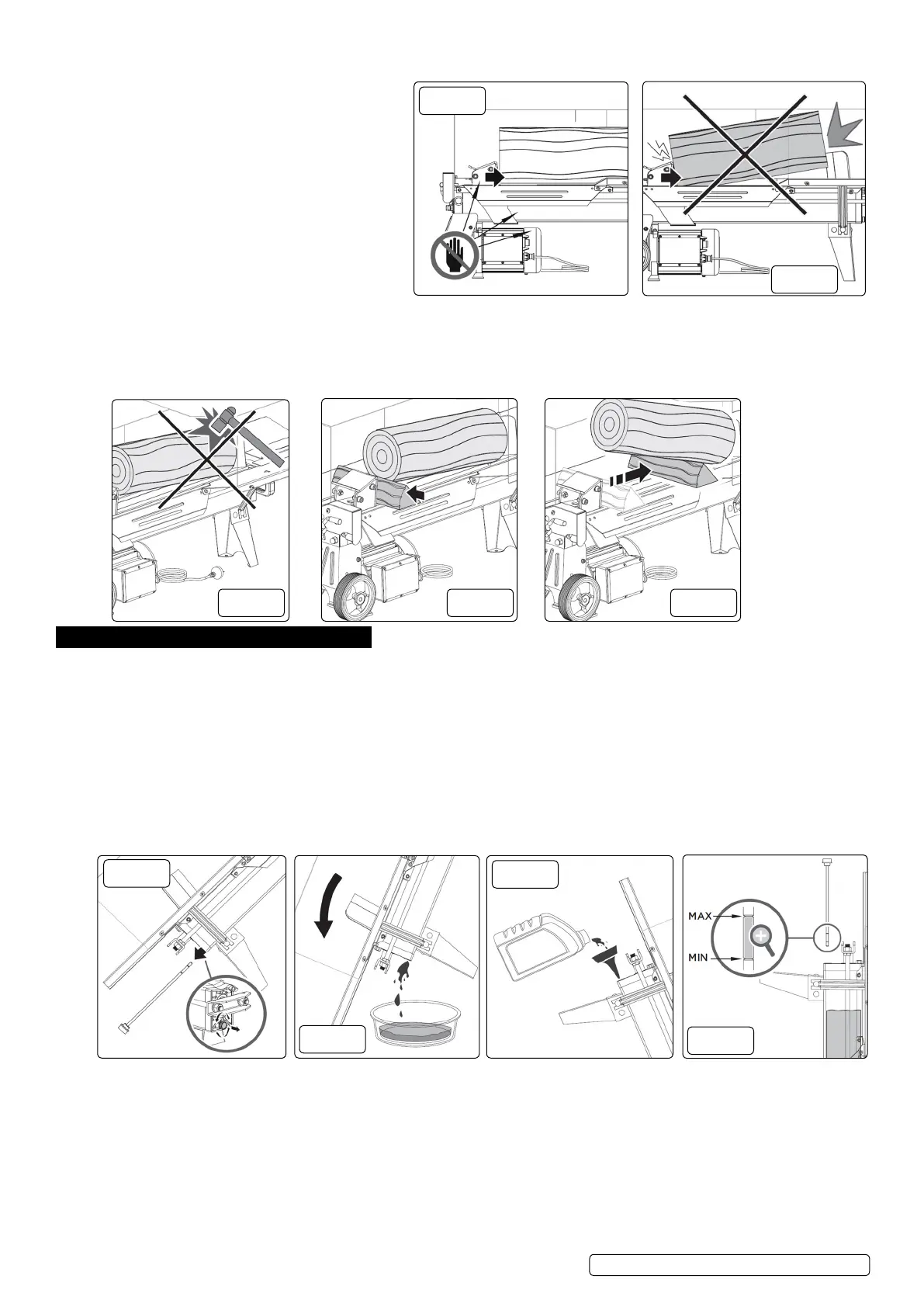

6.1.1. Unscrew Oil Drain Bolt with Dipstick to remove it (g.20).

6.1.2. Turn the log splitter on the Support Leg side over a 4 litres capacity container to drain the hydraulic oil off (g.21).

6.1.3. Turn the log splitter on the motor side.

6.1.4. Rell fresh hydraulic oil at the volume as per the hydraulic oil capacity of particular model (g.22).

6.1.5. Clean the surface of Dipstick on the Oil Drain Bolt and put it back into the oil tank while keeping the log splitter vertical (g.22).

6.1.6. Make sure the level of the relled oil is just between 2 grooves around the Dipstick (g.23).

6.1.7. Clean the Oil Drain Bolt before threading them back. Make sure they are tightened to avoid leakage before placing the log splitter

horizontally.

6.2. OIL LEVEL

6.2.1. Use a drain pan to aid in the removal of all used oil and particles (g.21). Remove oil drain plug (g.20) to drain oil from the hydraulic

transmission system. Examine oil for metal chips as a precaution to future problems.

6.3. SHARPENING WEDGE

6.3.1. This log splitter is equipped with a reinforced splitting wedge, which has a blade which is specially treated. After long periods of

operation, and when required; sharpen the wedge using a ne-toothed le removing any burrs or at spots on the edge.

g.15

g.16

g.17 g.18 g.19

g.20

g.21

g.22

g.23

Original Language Version

© Jack Sealey Limited

LS370H.V2 LS520H.V2 Issue 2 (3) 02/10/19

Loading...

Loading...