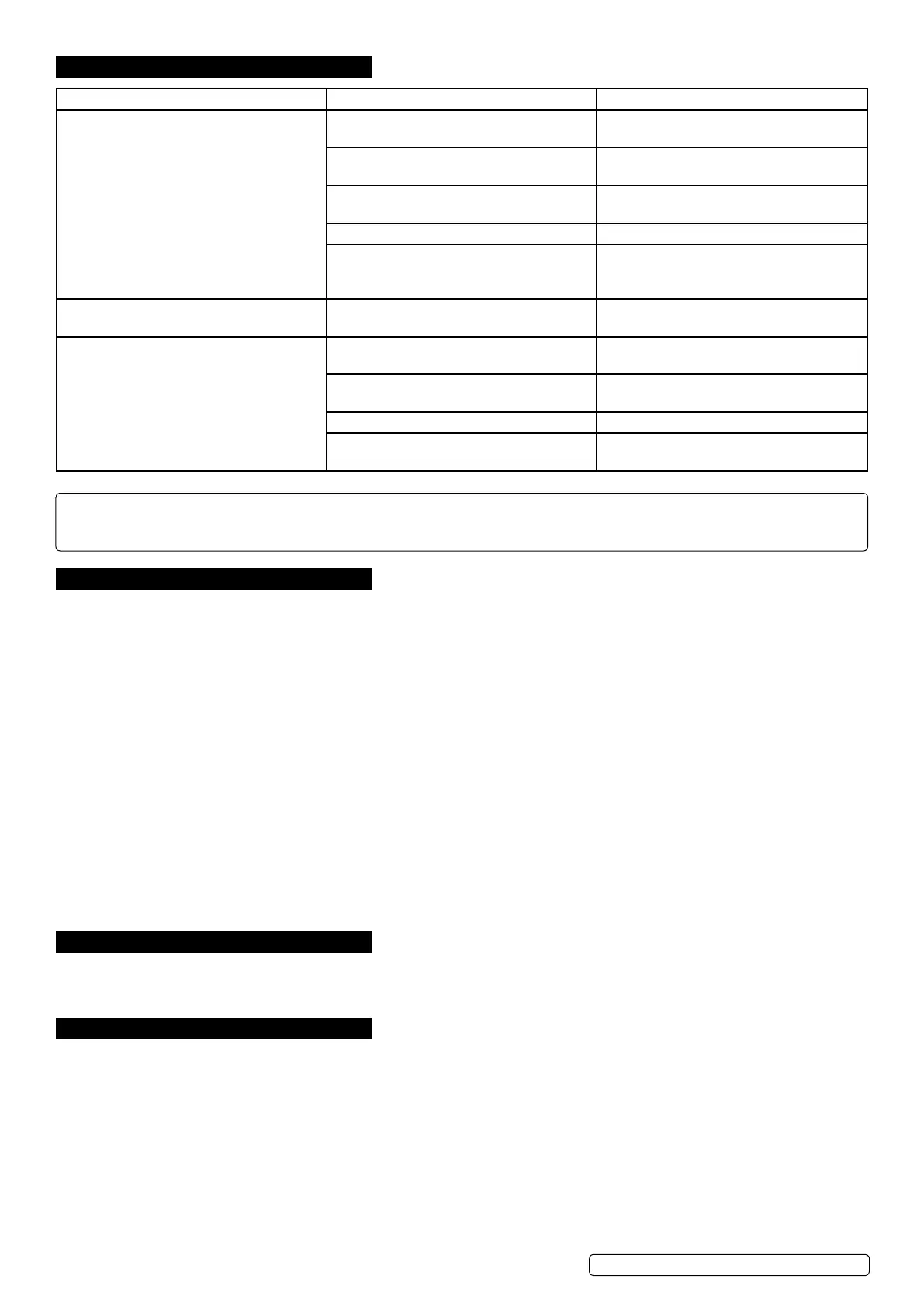

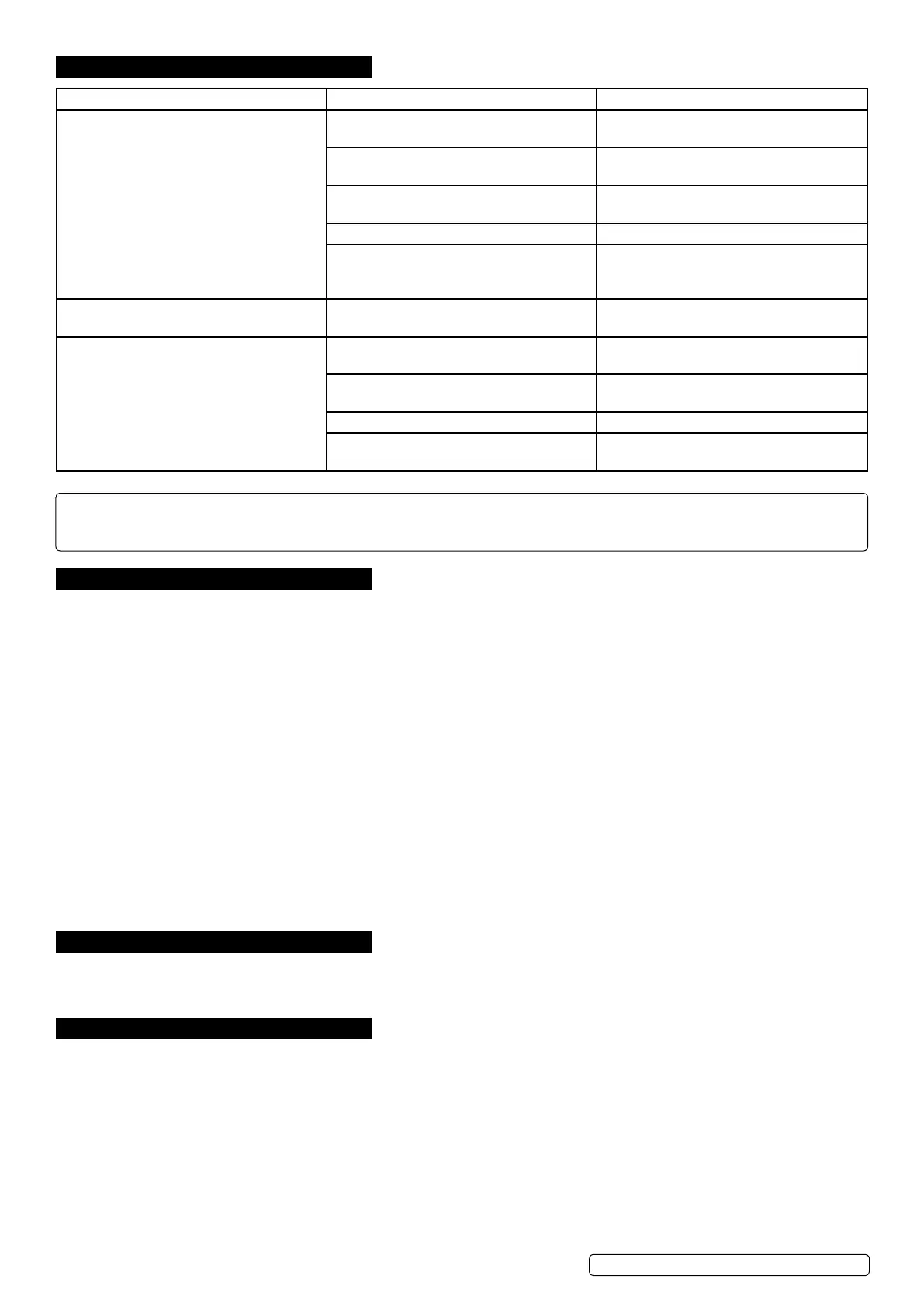

7. TROUBLESHOOTING

PROBLEM PROBABLE CAUSE REMEDY SUGGESTED

Fails to split logs Log is improperly positioned. Refer to “Log Splitter Operation” section for

perfect log loading.

The sizes or hardness of the log exceeds the

capacity of the machine.

Reduce the log sizes before splitting it on the

log splitter.

Wedge cutting edge is blunt. Refer to “Sharpening Wedge” section to

sharpen the cutting edge.

Oil leaks. Locate leak(s) and contact the Stockist.

Unauthorized adjustment was made on Max.

Pressure Limiting Screw. Lower max pressure

rating was set.

Contact the Stockist.

The log pusher moves jerkily, making

unfamiliar noise or vibrating a lot

Lack of hydraulic oil and excessive air in the

hydraulic system.

Check oil level for possible oil relling.

Contact the Stockist.

Oil leaks around cylinder ram or from other

points

Air sealed in hydraulic system while

operating.

Loosen Bleed Screw by 3 ~ 4 rotations before

operating the log splitter.

Bleed Screw is not tightened before moving

the log splitter.

Tighten the Bleed Screw up before moving

the log splitter.

Oil Drain Bolt with Dipstick is not tight. Tighten the Oil Drain Bolt with Dipstick.

Hydraulic Control Valve Assembly and / or

seal(s) worn.

Contact the Stockist

8. STAND SAFETY

9 Familiarise yourself with this product, application and limitations.

9 Maintain the stand in good condition.

9 Replace or repair damaged parts. Use recommended parts only. Non authorised parts may be dangerous and will invalidate the

warranty.

9 Keep the stand clean for best and safest performance.

9 Ensure the wood splitter is correctly secured on the stand before commencing work activity.

9 Ensure the ground is strong enough to withstand the weight of the stand, splitter and logs.

9 Maintain correct balance and footing. Ensure the oor is not slippery and wear non-slip steel toe-capped shoes/boots.

9 Keep children and unauthorised persons away from the working area.

8 DO NOT use the stand for any purpose other than tting log splitter Model No. LS370H.V2 and LS520H.V2.

8 DO NOT make any modications to the stand.

8 DO NOT use the stand if any parts are missing.

8 DO NOT exceed the rated capacity of the wood splitter.

8 DO NOT use as a platform.

9 When not in use, stand or store in a safe, dry location.

WARNING! The warnings, cautions and instructions in this manual cannot cover all possible conditions and situations that may occur.

It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be

applied by the operator.

WARNING! Must only be used correct height. Log Splitter must be securely mounted so that the hold-to-run two-hand control device

shall be located so that the height control actuators shall be between 850 mm to 1650 mm from the ground.

9. INTRODUCTION

Powder coated steel frame for added corrosion resistance. Suitable for attaching Model No. LS520H.V2 and LS370H.V2 Horizontal Log Splitter.

Labour and work time are kept to a minimum by creating a suitable working height. Attaching the wheels from Model No. LS520H and LS370H

enables easy and efcient movement of the stand.

10. SPECIFICATION

Height (with Log Splitter): ......................................... 1250mm

Height (without Log Splitter): ...................................... 740mm

HORIZONTAL LOG SPLITTER STAND FOR LS370H.V2 AND LS520H.V2

MODEL NO: LS520HST.V2

Original Language Version

© Jack Sealey Limited

LS370H.V2 LS520H.V2 Issue 2 (3) 02/10/19

Loading...

Loading...