1. Ensure that the machine is electrically isolated.

2. Select the correct size of chisel and auger, together with chisel bush, spanners and allen key.

3. Check that the chisel and auger have been correctly sharpened and are in good condition,

i.e. that the chisel is free from cracks and damaged points, and that the auger and cutting

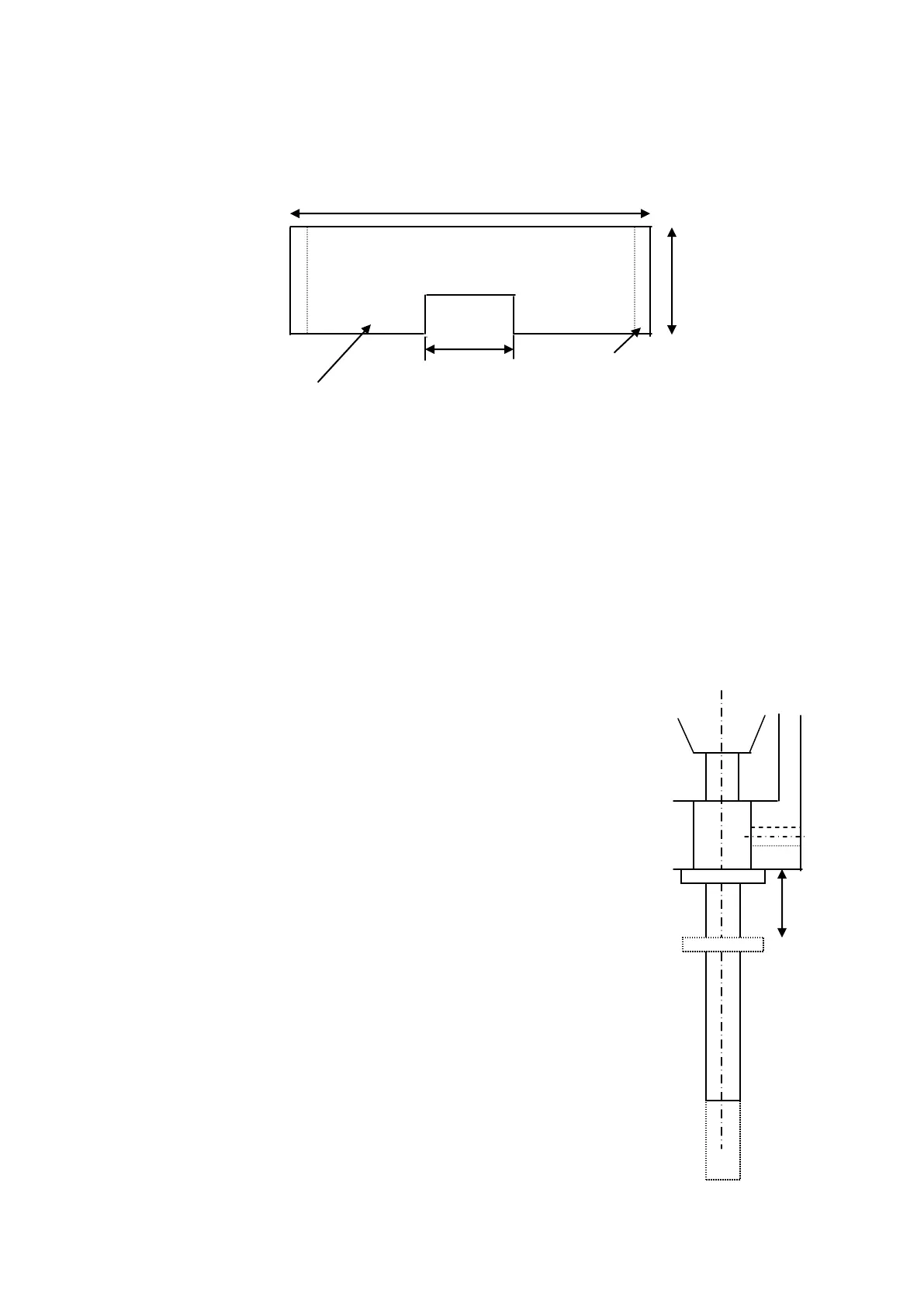

Insert auger (with chisel slotted onto it) into the

adjustable chuck to its uppermost limit and tighten in

place, the chisel will then rest upon the wings of the

auger in position as shown in dotted image.

Measure dimension ‘A’ carefully, then remove the auger

and shorten its shank end by a distance 1mm less than

dimension ‘A’ measured.

Insert chisel into the chisel socket until the chisel

shoulder butts firmly up to the underface of the chisel

socket and lock screw ‘B’.

Insert auger once more to its uppermost limit. Its

scribing wings should be found to clear the chisel

internal cutting bevel by the distance allowed. Finally,

tighten the auger and the machine is then ready for

cutting.

Note: the lower point on the bit must clear the bottom

point of the chisel and not rub against the chamfer. It is

advisable to file a flat on the chisel to enable the

locking screw to grip firmly and not burr the shanks,

making removal difficult. Always ensure the chip relief

in the chisel is left to right and not front to back and

always cut away from the relief to ensure good chip

ejection.

The chisel should be mounted with its chip ejector slots

facing along the workpiece. Rotate the auger by hand to

check that it runs freely without rubbing

Loading...

Loading...