4-4 Adjustment

.

'2'S'v/·.:i111

I •

..,.i

\.:!.

\

Adjustment

I

Adjust-

I

Test

Test

Adjustment procedure Purpose

I Faults due

to

incom-

name

Jment

point

point

·

equipment

plete adjustment

VR403 TP-PLCK

Frequency Shon both terminals of

C410

To

reproduce

•

It

takes

more

time

to

(Connect counter

or

connect TP-D

and

GND.

a reference

search for

the

Adjust variable resistor

clock signal

Small

each track.

1. vco

probe's VR403 so the frequency of during

CD

the signal at test

pin

PLCK is

I

adjustment

ground

to

play.

•No

play

pos-

GND)

4.320 ±

O.OSMHz.

Large

sible.

VR401

TP-X

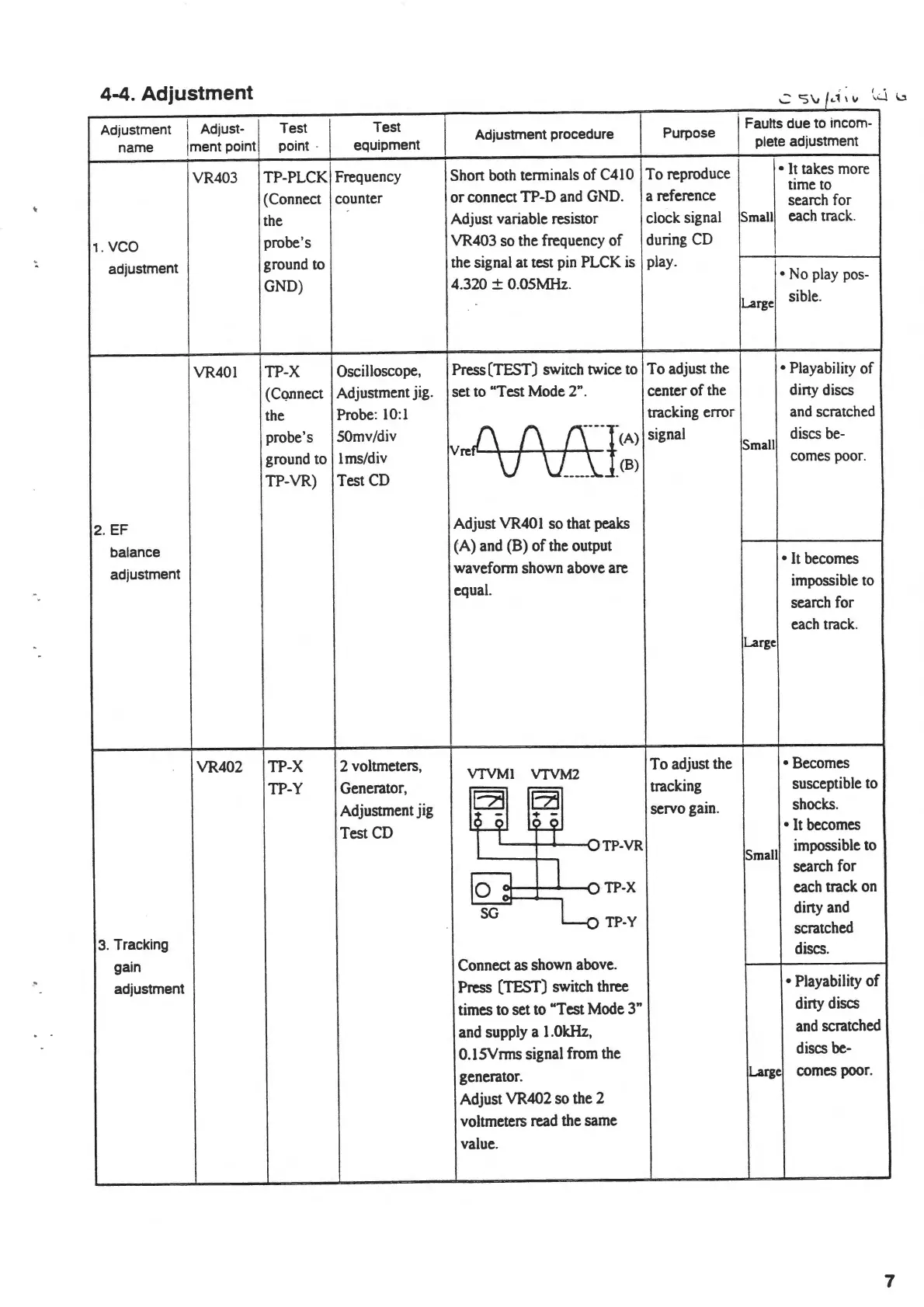

Oscilloscope, Press (TEST) switch twice

to

To adjust the

• Playability

of

(CQllnect

Adjustment jig. set

to

"Test Mode 2".

center of

the

diny discs

the

Probe:

10

:1

tracking error

and

scratched

probe's 50mv/div

v

..

.O

(\

rcy)

signal

discs

be-

Small

ground to I ms/div

vv=i

_(B)

comes

poor.

TP-VR) Test

CD

2.EF

Adjust VR40 I so that peaks

balance

(A) and (B)

of

the

output

adjustment

waveform shown above are

•It

becomes

equal.

impossible

to

search for

each

track.

Large

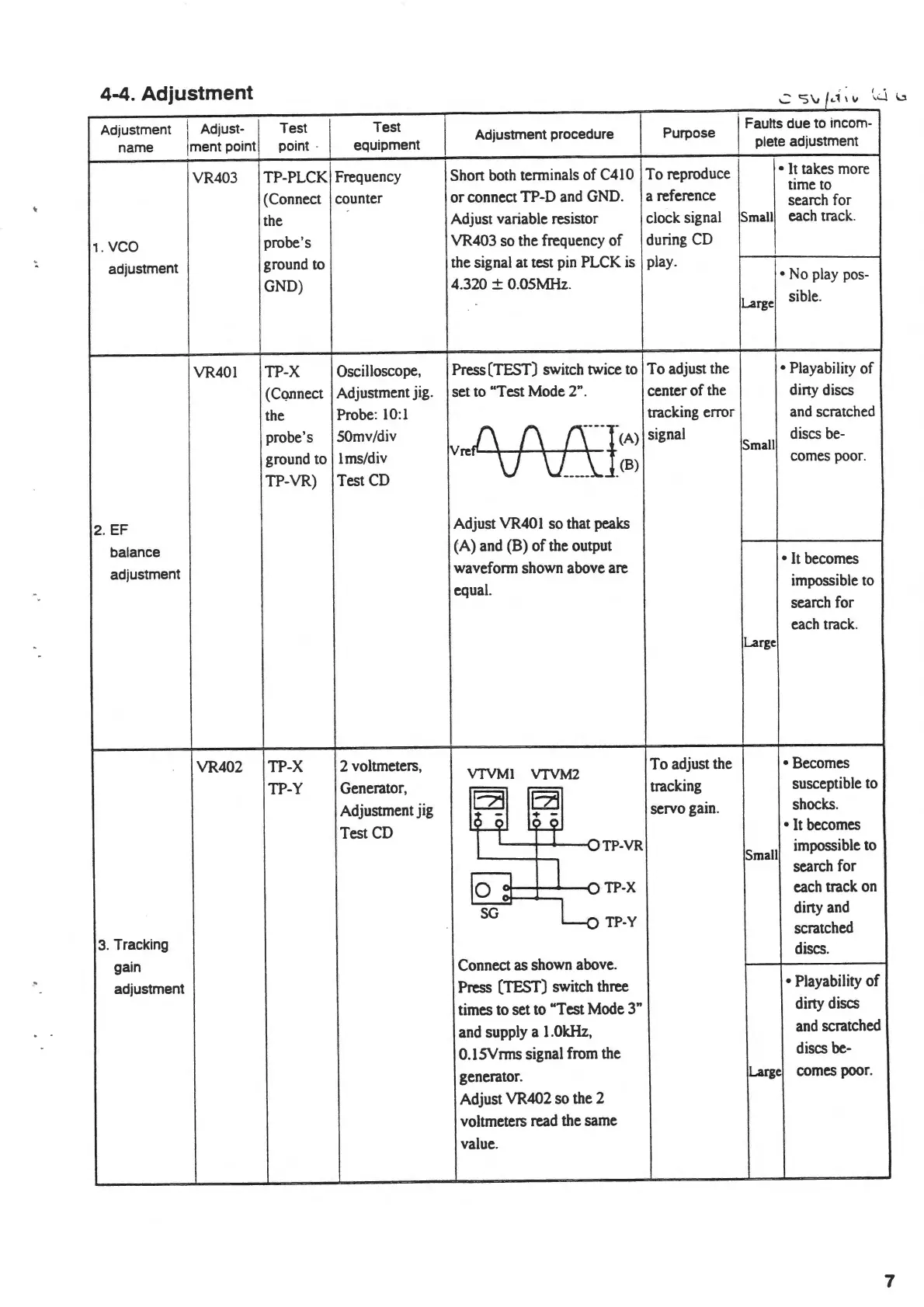

VR402

TP-X

2 voltmeters,

VTVMI

VTVM2

To adjust the •Becomes

TP-Y Generator,

EZI

ai

tracking

susceptible to

Adjustment jig servo gain.

shocks.

-

Test

CD

'O

•It

becomes

)

VTP-VR

Small

impossible to

lo3

I

search for

vTP-X

each track

on

-

diny

and

SG

TP-Y

scratched

3.

Tracking

discs.

gain

Connect as shown above.

adjustment

Press (TEST) switch three

• Playability

of

times to set to "Test Mode 3"

diny discs

and supply a l

.OkHz,

and

scratched

O.lSVnns signal from the

discs be-

generator.

Large

comes

poor.

Adjust VR402 so the 2

voltmeters

read

the same

value.

7

Loading...

Loading...