semshred.com | 508.366.1488

3.2 Electrical Wiring

• The machine includes an appropriate power cord and male plug. The unit is activated by a top

mounted selector switch with indicator light.

• Access to the cutting chamber for service is provided by the main cabinet door. A safety limit

switch activated by the main door prohibits operation when door is open.

Note: Some motors have manual overload reset button on motor, others are automatic.

Each machine will be clearly marked.

• If for any reason the machine is rotating in the wrong direction, remove metal plate on

motor and change leads as shown on plate diagram.

Note: Motors are normally dual voltages, 115/230 but can only be operated at the specific

voltage as wired at the factory. If voltage change is required in the field, contact factory for

proper instructions.

All electrical schematics and diagrams are available as a PDF upon request. Contact SEM for more

details.

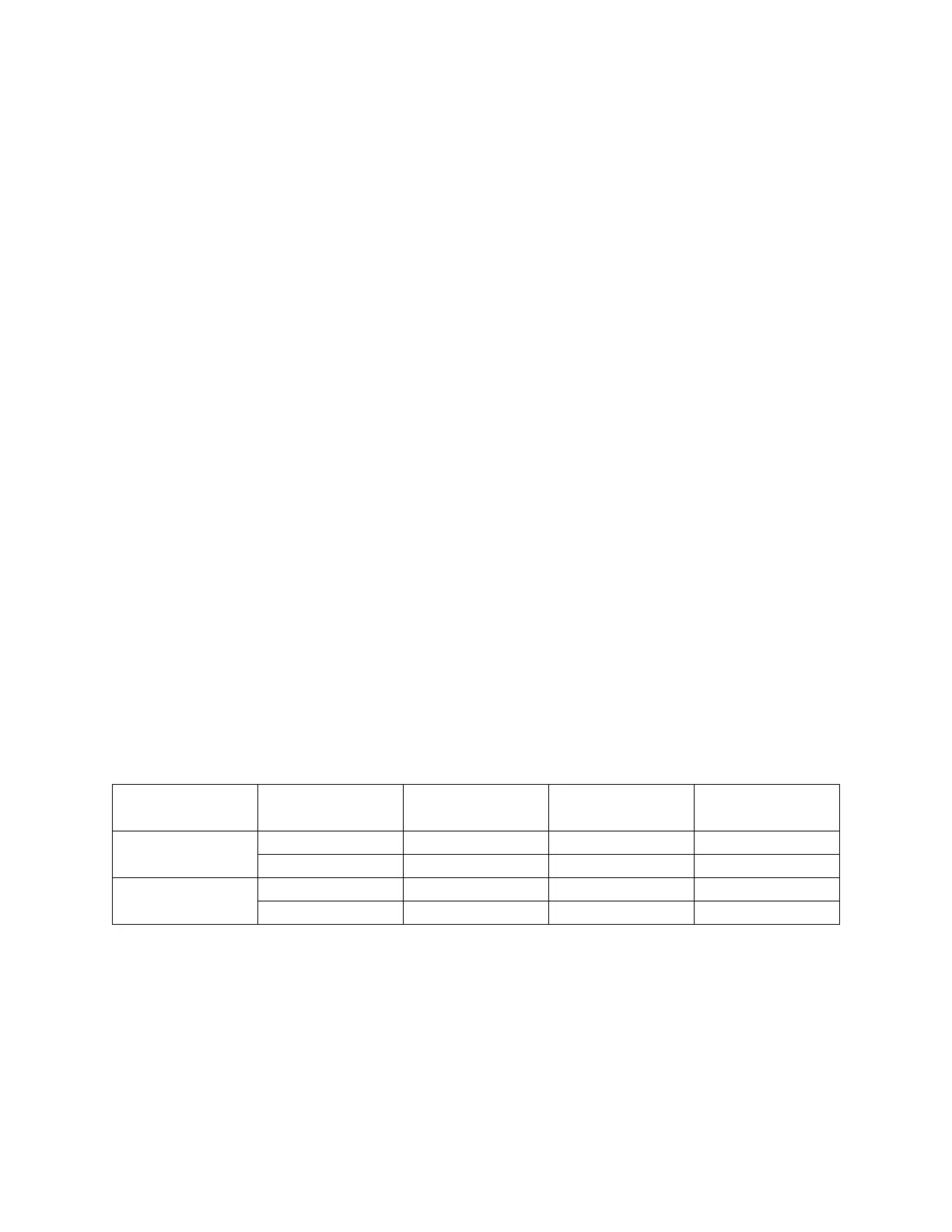

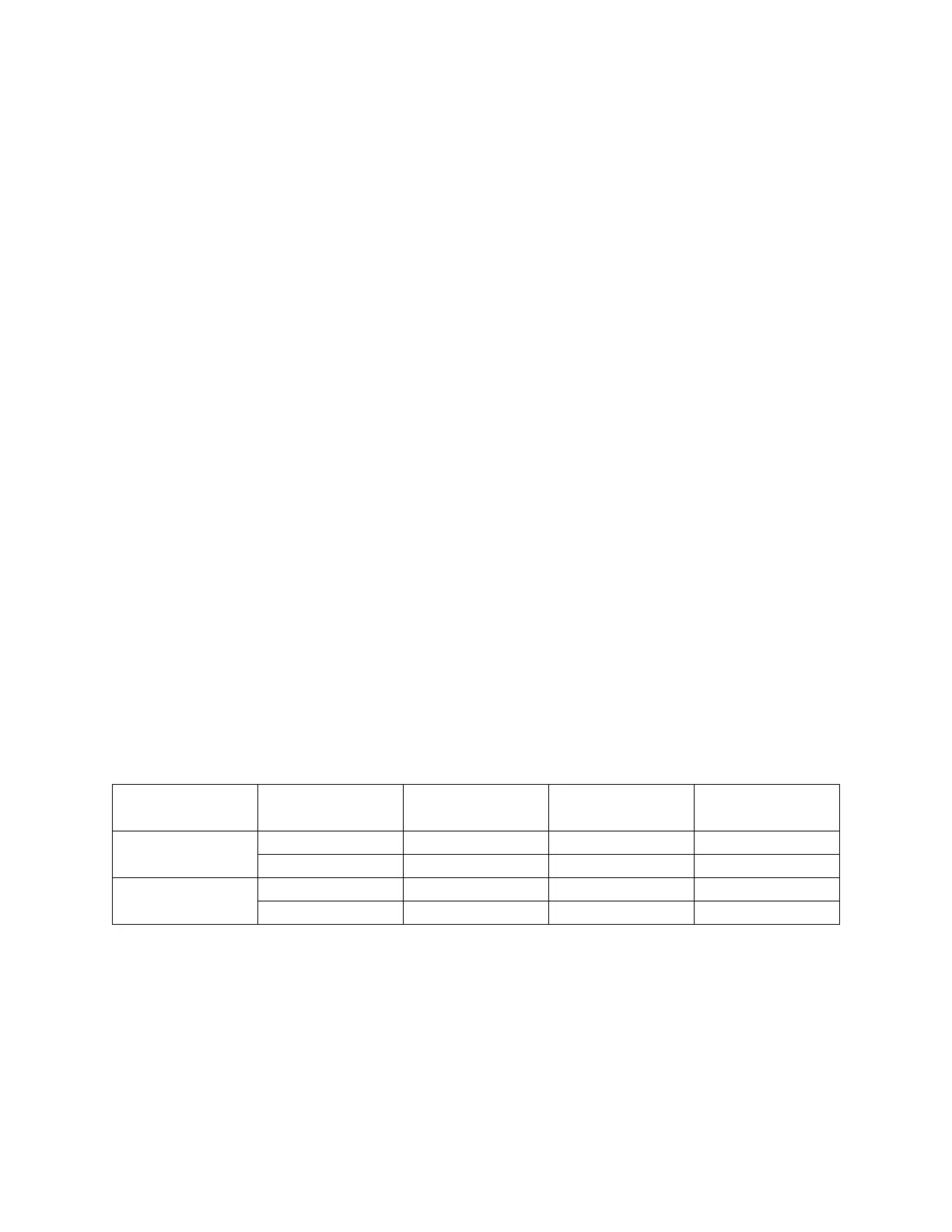

3.3 Electrical Installation Options and Power

• Must be completed be a licensed electrician, see table below for plugs supplied with machine.

• Provide an appropriate receptacle with a cord and hang from a power disconnect switch.

• Provide an appropriate flanged receptacle and mount to a power supply.

• Cut off supplied plug and hardwire the power cord to a power disconnect switch.

Note: For overseas units, the plug must be specified at the time of purchase. These units

typically come with an open-ended cord.

Loading...

Loading...