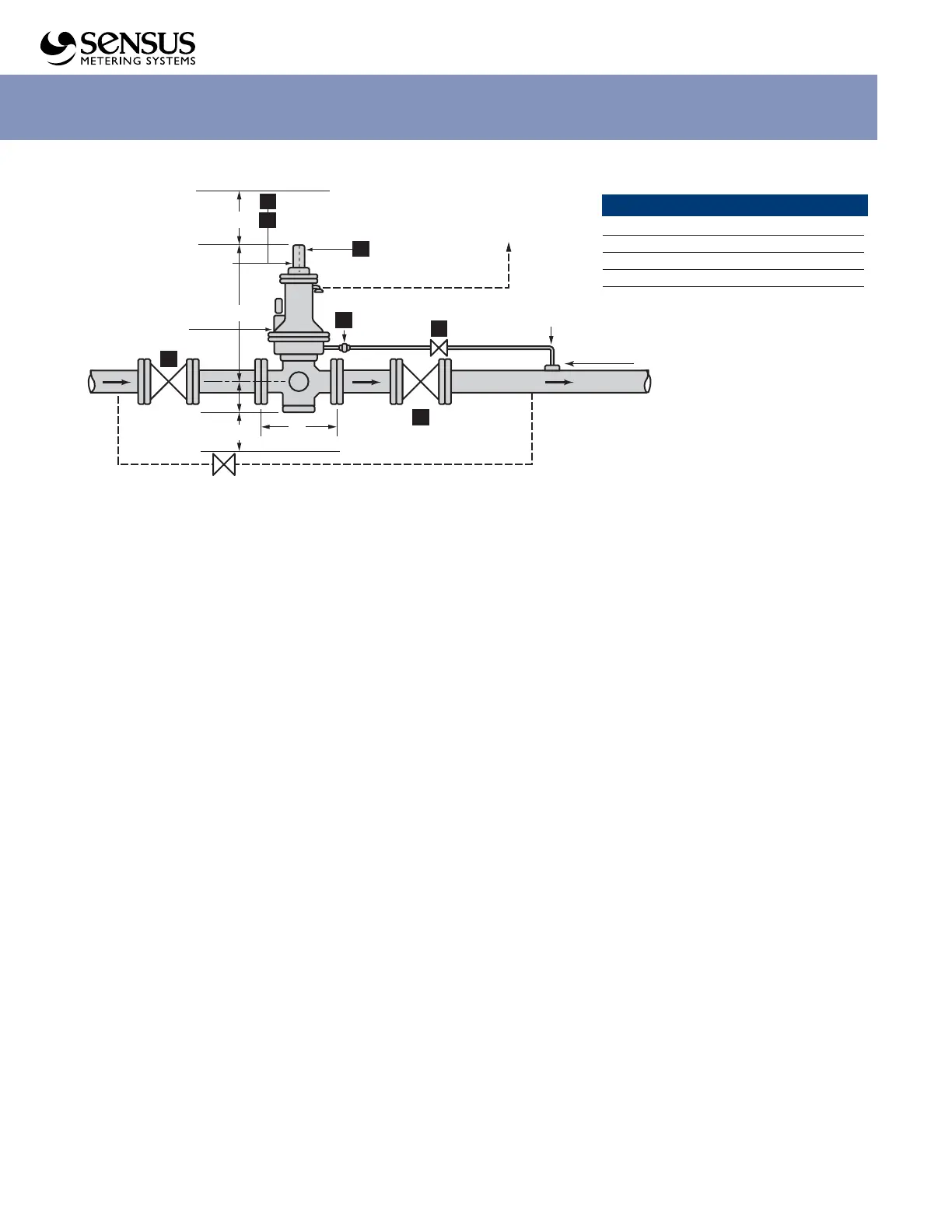

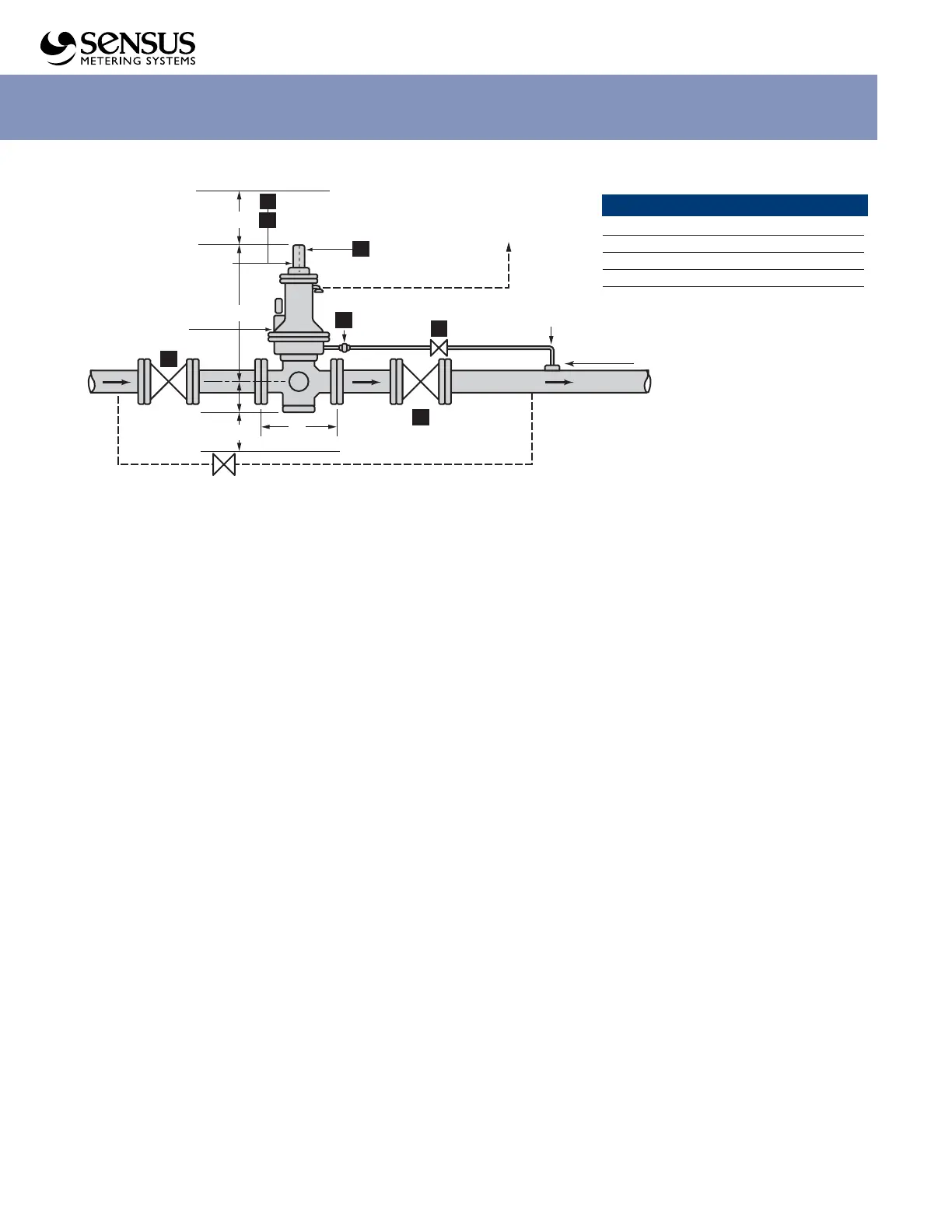

5"

(Minumum Service Space)

Self Adjustment

Screw for Desired

Outlet Pressure

2

3

1

Vent

Remove Vent

(If Required)

461-57S

20.5"

20

A

Downstream

Control Line

Control Line

Connection

B

Outlet

8"

4"

F

Minumum

Service Space

(Bypass (If Required)

Inlet

C

3

Installation and Maintenance Instructions

Model 461-57S Regulator

Servicing and Adjustment

General Notes (see Illustration on page7)

1 Make sure the regulator is entirely depressured before servicing.

2 A quick visual inspection of the valve can be made by

removing inspection plates 33 from the sides of the body.

These also provide greatly improved access to the valve when

servicing or adjusting.

3 The diaphragm 11d, the springs 9, and all other parts from

the diaphragm up (except the 11h stud) are interchangeable

with the Model 441-57S Regulator. Valve and body parts are

interchangeable with other 461 Regulators

(461-S, 461-X57, 1100, 1200, 461-2100).

4 Use lubricants sparingly and with care to avoid exposing tacky

surfaces to the gas stream. Such surfaces could cause dirt

accumulation on close clearance parts.

Use moly or silicone type lubricants. Avoid the use of

petroleum base types.

Lubricate the stem 12b, guide 12j and stem O-rings 12a

& 12n with dry silicon lubricant to help assure free

movement and a tight seal.

An application of lubricant to other O-rings and the tetraseals

in the regulator will also help assure their tightness.

5 When using double seat balanced valve assembly, bushing 13

must be screwed firmly into place. When using single seat

balanced valve assembly, bushing 13 must be removed.

To Service Double Seat Balanced Valve Assembly

1 Remove seal cap 1, back off adjusting screw 2, remove

housing cover 6, and remove spring 9.

2 Remove bottom inspection plate 14, and unscrew valve

assembly intact from diaphragm assembly (12b unscrews

from 11h).

3 Unscrew orifice 18 with socket wrench (1-1/2" hex, deep

socket). Remove orifice 18 and valve assembly intact

through bottom opening.

4 If valve assembly and orifice are alright, screw orifice 18

firmly into place. Replace without disturbing set screw 12g.

Top end of 12b screws into 11h until it bottoms and should

then be backed off 1/2 to 1 full turn.

5 If new parts are needed, disassemble valve assembly by

loosening set screw 12g and unscrewing 12h from 12b, and

then unscrewing nut 12e and part 12j.

6

Replace parts as required, then reassemble upper half valve

assembly (parts 12a, 12b, 12c, 12d, 12e) and lower half

(parts 12f, 12g, 12h, 12c, 12d, 12j).

7 Insert through bottom opening:

a. upper half valve assembly - screw 12b onto 11h until

it bottoms then back off 1/2 to 1 full turn.

b. orifice 18 - screw firmly into place.

c. lower half valve assembly - screw onto upper half

by 3 or 4 turns (12h screws onto 12b).

8 Make the valve lock-up adjustment. Seat the upper valve

against orifice 19 while screwing up the lower half valve

assembly (12h screws onto 12b until the lower valve is

seated against 18). Then, firmly tighten set screw 12g.

a. To seat the upper valve against orifice 19, either reach

it through the body side opening or remove diaphragm

assembly and pull top end of stem 12b upwards.

b. Tighten 12g with screwdriver through body side

opening. If necessary, turn the entire valve assembly

(carefully – do not disturb adjustment to face 12g

toward side opening).

c. 12g must tighten against flat area at top of 12h to

correctly lock the adjustment.

9 Screw entire valve assembly up (top of 12b screws onto

lower end of 11h until it bottoms), then back off 1/2 to 1

full turn - this is important.

10 Complete assembly as per steps 6 thru 10 under

“To Assemble 461-57S”.

Figure 1. Typical Arrangement and Dimensions (indoor and outdoor installation)

Regulator Body Type (Face to Face, in.)

Screwed6-1/2

Flanged ANSI 125 10

Flanged ANSI 250 10-1/2

Flanged ANSI 300 10-1/2

Flanged ANSI 600 11-1/4

Loading...

Loading...