.

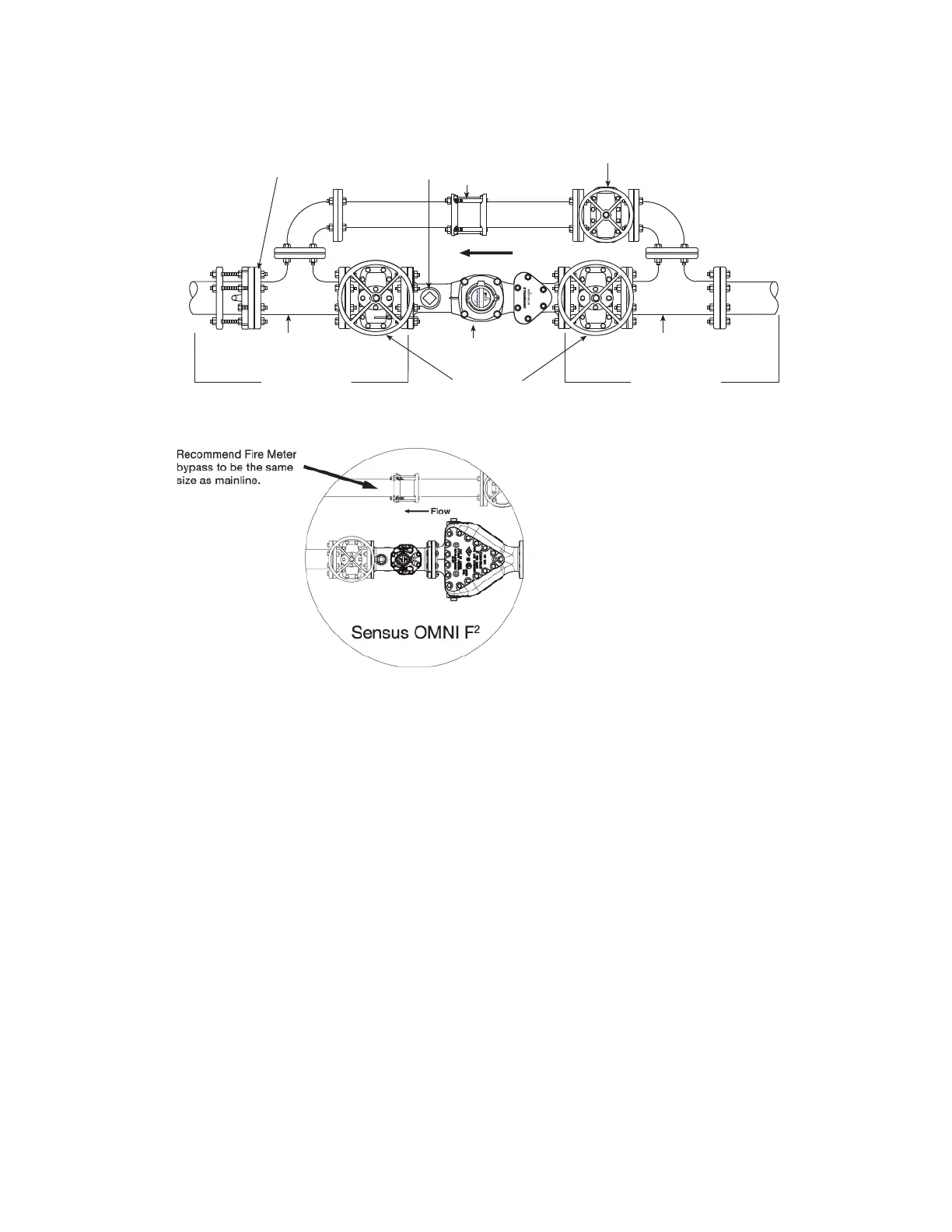

2 Dia. Minimum

Straight Pipe

Recommended

Bypass Tee

Full-Open

Gate Valve

Sensus OMNI Meter

(Shown)

2 Dia. Minimum

Straight Pipe

Recommended

Bypass Tee

Test Outlet

w/Locking

Ball Valve

Smith-Blair Coupling

Bypass Valve Closed

During Meter Use

Upstream

Downstream

Smith-Blair Flange Coupling

Adaptor w/Anchor Studs

(Optional Flexibility)

Flow

1

/

2

1

/

2

OMNI Installation 7

5. No mechanical stresses should be exerted on the meter when installed in the

pipeline. The pipeline flanges must align with the meter flanges, the distance

between the flanges must match the meter body length, and the weight of the

meter must be supported evenly. Mis-alignment stresses can cause the meter

body or flanges to crack; thus, when the pipeline is under pressure, flooding can

occur.

6. The meter must not be subjected to pressures higher than the pressure rating

pr

inted on the data sheet. Too high pressure can cause leaks or burst the meter

body.

7. Gaskets must not protrude into the pipeline or be misaligned.

8. The pipeline must be thoroughly flushed before ins

talling the meter to prevent

damage from debris.

9. The flow direction of the meter (arrow on the meter body) must correspond with

t

he flow direction in the pipeline.

10. After installation of the meter, the

pipeline must be filled with water very slowly to

prevent the meter being damaged by surges. Filling the pipe too rapidly can cause

air/water surges, which can destroy the meter insert.

11. The installation site should be chosen to

prevent air bubbles collecting in the

meter and the pipeline must always be completely filled with water. Installation of

a meter at the highest point in a pipeline must be avoided.

Loading...

Loading...