8 Sentry Equipment Corp

Service

Before servicing, ensure that the sample line is isolated and cannot be opened during this

service. This is necessary to prevent exposure to high pressure and/or hot materials. Allow the

VREL valve to cool to a comfortable touch prior to commencing service.

No normal maintenance is required. Replacement parts available are listed below.

Replacement Parts

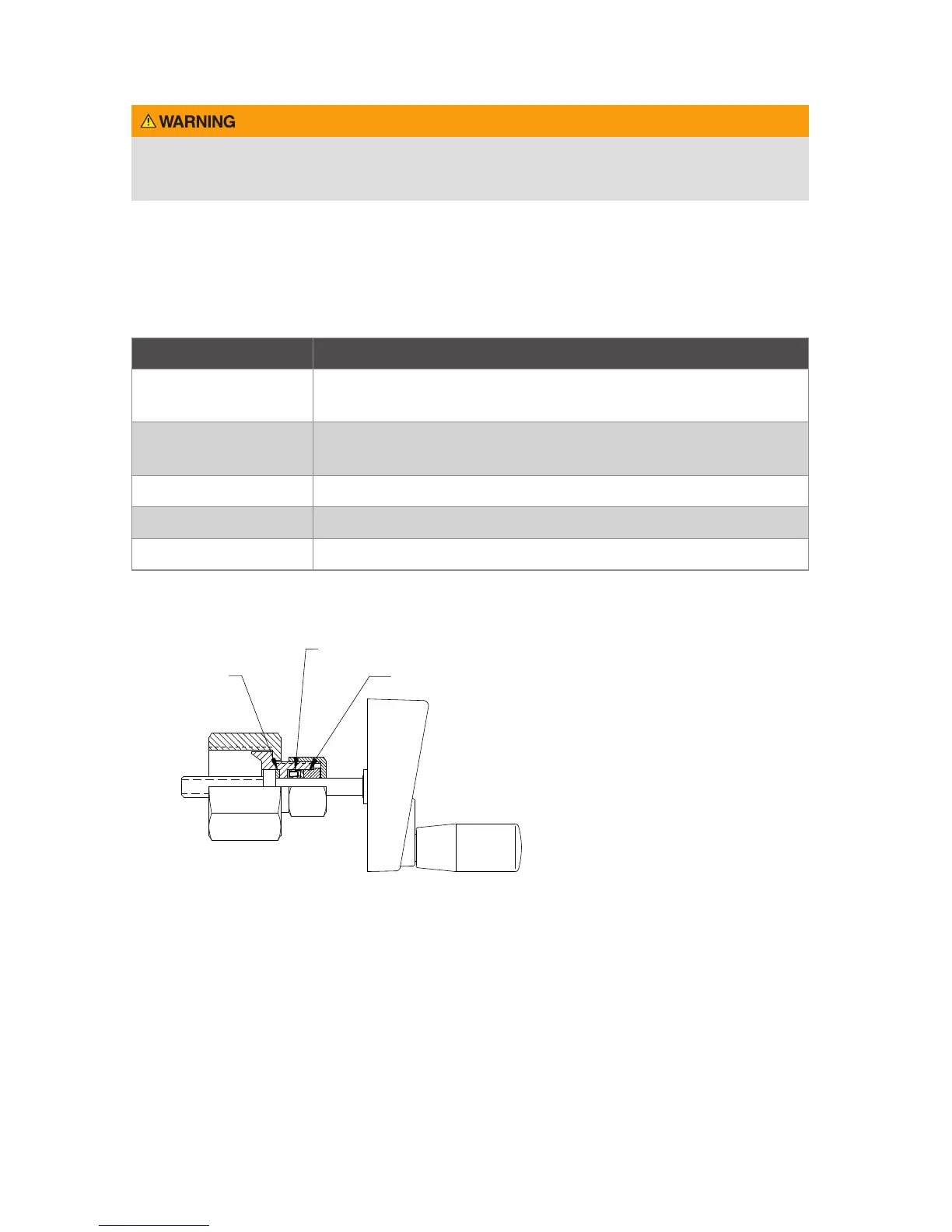

Part Number Item

6-02302C VREL Valve Seal Kit (Figure 2) (includes thrust washer, spring

seal & backup washer)

6-02302E Valve Handle & Rod Assembly (Figure 3)

– includes both 6-02302A and 6-02303A

6-02302A Valve Handle Assembly Only (Figure 3)

6-02303A Tapered Rod & Nut Assembly Only (Figure 3)

6-04605A VREL Swivel Handle

Figure 2. 6-02302C – VREL Seal Kit

Thrust Washer

Spring Seal & Backup

Bushing

Ratings

Wetted materials: 316 Stainless Steel

Weight: 4 lbs

Pressure: 5000 psig at 300°F

(345 barg at 149°C)

Loading...

Loading...