5 – 4

AY-XPC12PU

“ “ mark

[7].DETACHING THE UNIT FROM THE MOUNTING PLATE

Push the “ “ marks at the bottom of the indoor unit to

release the hooks from the mounting plate, and pull the

unit toward you.

Flaring the pipe end

(1) Cutting with a pipe cutter

Cut at a right angle.

(2) Deburring

Allow no cuttings in the pipe.

5

CONNECTING THE REFRIGERANT PIPES

90°

Connecting the pipes

-

door unit.

(1)

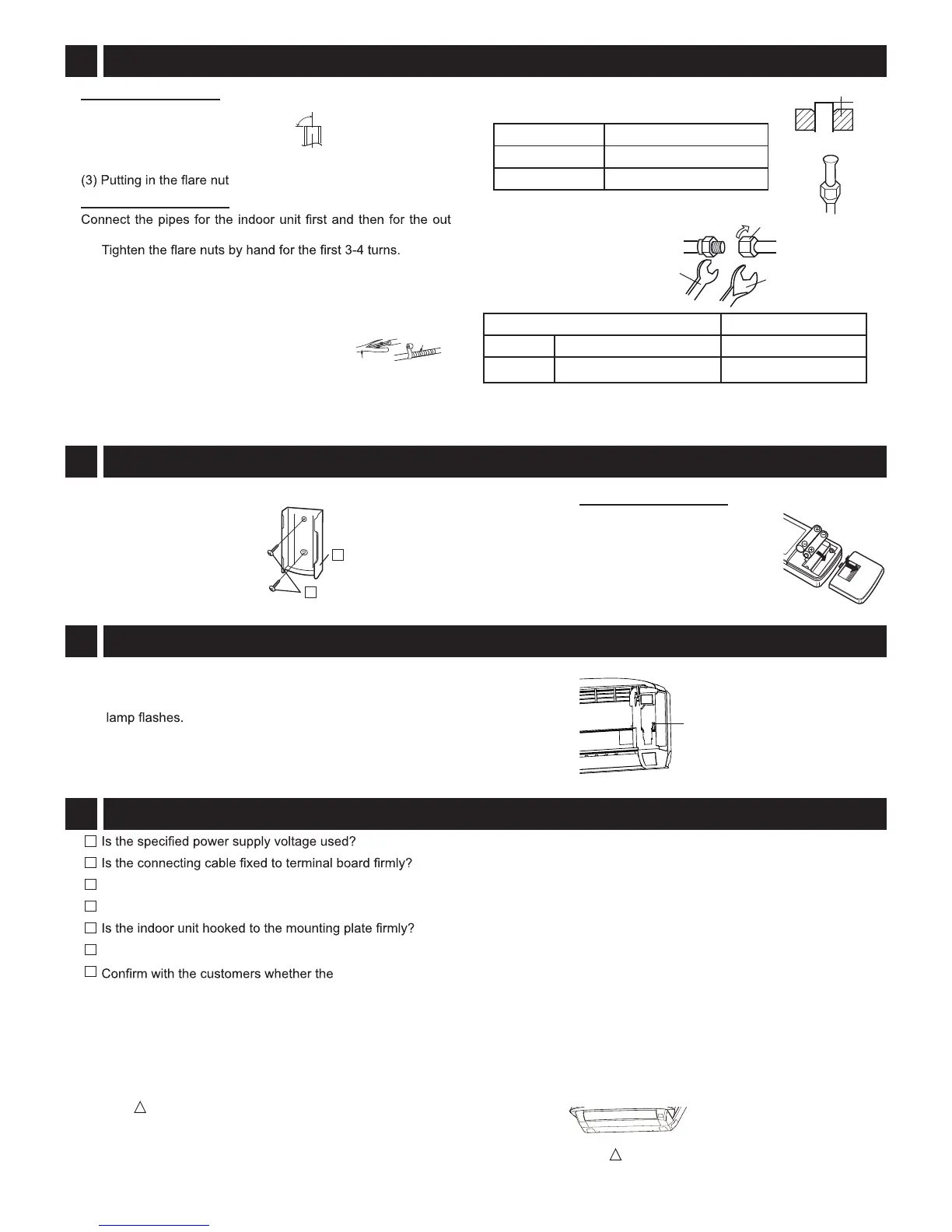

(2) Use a wrench and torque wrench to tighten up the pipes.

Do not over tighten the pipes. It may be deformed or damaged.

(3) Wind coating tape around refrigerant pipes together with

drain hose and cable for general.

Lay the drain hose below the pipes.

The thermal insulation should cover both

the gas and liquid pipe. As insulation, use

polyethylene foam 6 mm or thicker.

7

TEST RUN

(1) Start the operation with the remote control.

(2) To start test run in cooling, hold down the AUX button on the unit

for over 5 seconds until a beep sound is heard and an operation

(3) Make sure the system runs well.

To stop the operation, press the AUX button again.

8 ITEMS TO CHECK

Is the earth wire connected properly arranged?

Is the drainage properly?

Is there any gas leakage at the pipe connection?

5°F/-15°C AUTO OFF function will be used or not.

EXPLANATION TO CUSTOMER

Ask the customer to carefully read the operation manual.

.

F the remote control holder

to the wall with the short

screws.

6L

5 SHORT

Loading the batteries

(1) Slide and open the cover.

(2) Insert the batteries.

(3) Replace the cover.

(4) T button

using a thin stick.

6

HANGING THE REMOTE CONTROL

Liquid pipe

Gas pipe

Insulation

Drain hose

Cable

A

(4) Flaring

Flare processing dimensions(A)

AlooT

R410A tool 0-0.02 in (0 - 0.5 mm)

Conventional tool 0.04-0.06 in (1.0 - 1.5 mm)

(5) Checking

To be ared perfectly circular.

Flare nut not missing.

Flare nut

Wrench

Torque wrench

Flare nut tightening torque

euqroTezis epiP

Liquid side

1/4" (ø 6.35 mm) 11.8±2 ft·lbs·m)

Gas side

3/8" (ø 9.52 mm)

28±3 ft·lbs (·m)

AUX

Loading...

Loading...