3-2. Mounting

(1) Machine the mounting hole by referring to the panel-cut illustration in Section 3-3.

(2) Applicable thickness of the mounting panel is 1.2 ~ 2.8mm.

(3) As this product provides mounting fixture, insert the product into the panel.

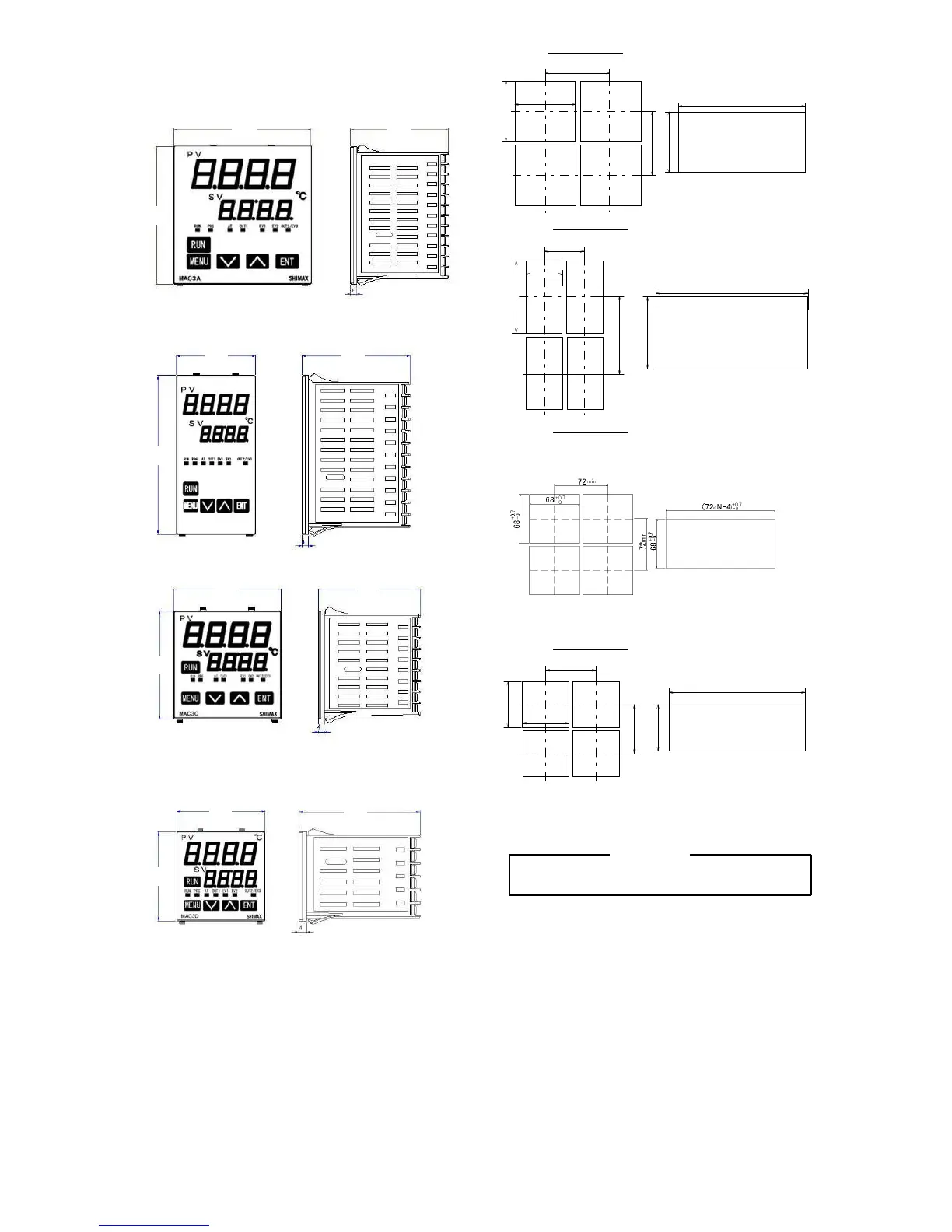

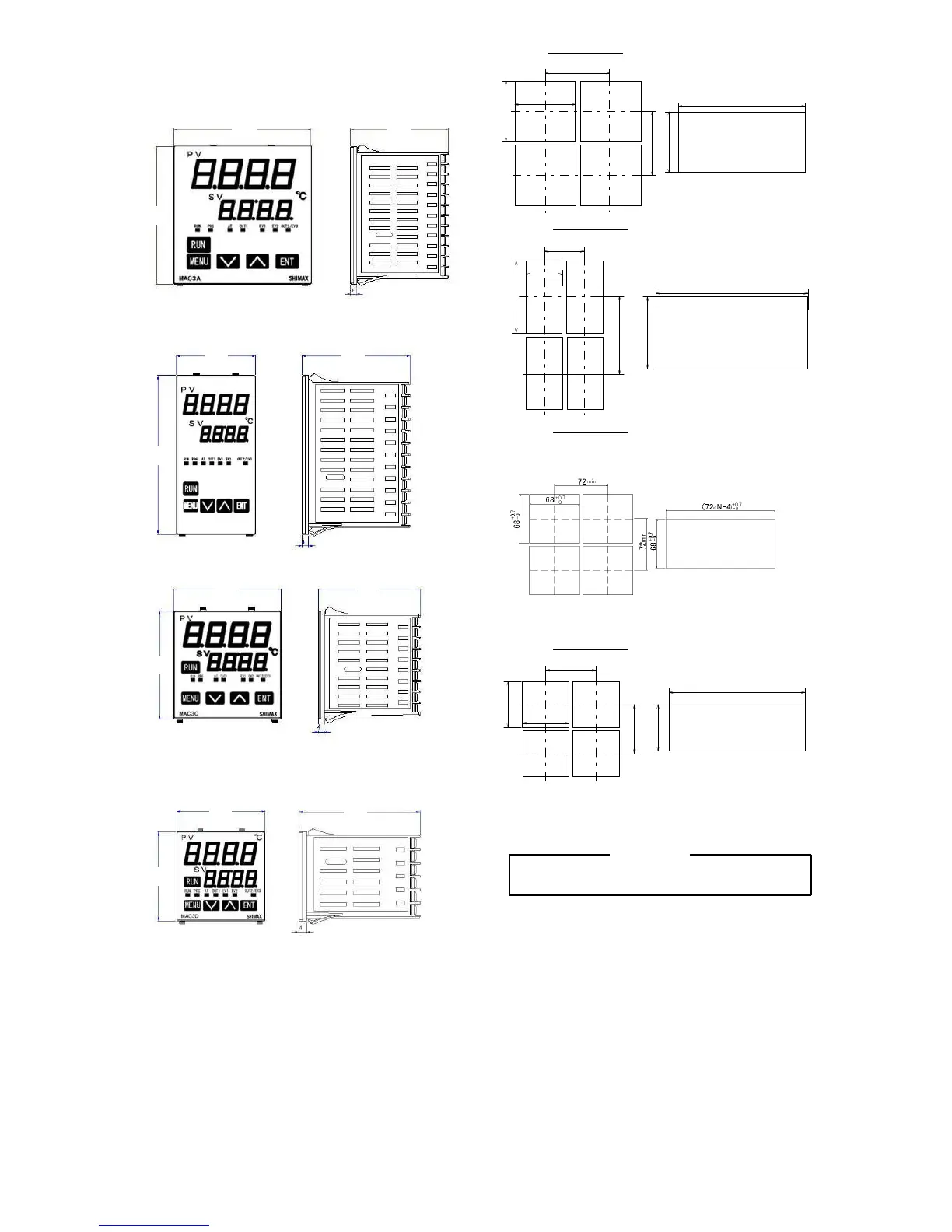

3-3. External dimension and panel cutout

MAC3 external dimensions (unit: mm)

MAC3 panel cutout (unit: mm)

MAC3A 96×96size

92

+0 .8

-0

92

+0 . 8

-0

(9 6 ×N-4)

+0 . 8

-0

96 以 上

92

+0 . 8

-0

96 以 上

In the case ofhorizontal proximityattachment by asingle hole

N:

Number

MAC3B 48×96size

48 以 上

96 以 上

9 2

+0. 8

-0

45

+0. 6

-0

(48 ×N -3)

+0. 6

-0

92

+0 .8

-0

In thecaseof horizontal proximity attachment by asinglehole

N:

Number

MAC3C 72×72size

MAC3D 48×48size

45

+0 .6

-0

45

+0 .6

-0

4 8 以 上

( 4 8 ×N -3)

+0 .6

-0

45

+ 0. 6

- 0

48 以 上

Inthecase of horizontalproximityattachment by asinglehole

N:

Number

Note: Proximity attachment by a single hole is possible only in the case of horizontal direction.

When an apparatus that was attached in vertical direction is removed, a dedicated detachment

tool is required.

3-4.

3-4.3-4.

3-4.Wiring

「

「「

「

WARNING」

」」

」

◎Do not turn on electricity while wiring to avoid an electric shock.

◎Do not touch a terminal or live part while turning on electricity.

(1) Make sure that wiring operation is properly done in line with a terminal wire diagram of section 3-5.

(2) Choose a suitable compensation lead wire in the case of thermocouple input.

(3) In the case of resistance bulb input, resistance value of each lead wire must be less than

5Ω and that of three lead wires must be equal.

(4) Do not wires an input signal line inside of an electric wire pipe or a duct same with the

high voltage line.

(5) Shield wiring (single point grounding) is effective against static induction noise.

(6) Wiring twisted at equal short intervals is effective against electromagnetic induction noise.

Loading...

Loading...