MAGNA 10ER Owner’s Guide v1.01 restored by Everett L. Davis – 2016 - Donated without cost to the worldwide Shopsmith Community

9

The headstock spindle is supported by ball bearings at

either end of the quill, which is a movable steel sleeve.

When the feed lever is turned, a simple rack-and-pinion

gearing moves the quill and the spindle it supports.

When pressure on the feed lever is released, a coil spring

returns the quill and spindle to their normal, retracted

position. This spring is enclosed in a metal case on one side

of the head-stock. Spring tension is adjusted at the factory;

if a different tension is required, adjust as follows:

Remove nut from depth stop-rod; turn feed lever until quill

rack disengages from pinion gear. Keep turning feed lever

until desired tension is obtained. Remember that the

external spline on the spindle and internal spline on the

pulley shaft must mate; hold the pulley and turn spindle

slightly when reinserting the quill and spindle.

LUBRICATION - To maintain quiet and smooth spindle

and quill operation, regularly place a few drops of

medium-weight machine oil on the outside of the quill.

Extend the quill its full length and force a small amount

of cup grease into the splined section of the spindle

and drive shaft.

Release the quill and work it back and forth to distribute the

lubricant evenly. Headstock "chatter" can nearly always be

eliminated by greasing the spline.

CARRIAGE - The precision-bored carriage (Fig. 5) is locked at any

position on the ways by the carriage lever, which applies soft

metal wedges against the tubes. Carriage knobs on either side

secure the table or lathe tool-rest at desired height.

CAUTION: Be sure that both carriage lever and knobs are

tightened before starting any operation.

The stud extending from side of the carriage facing the head-

stock automatically (after initial adjustment) stops the carriage in

the correct position in relation to the headstock for using the

circular saw.

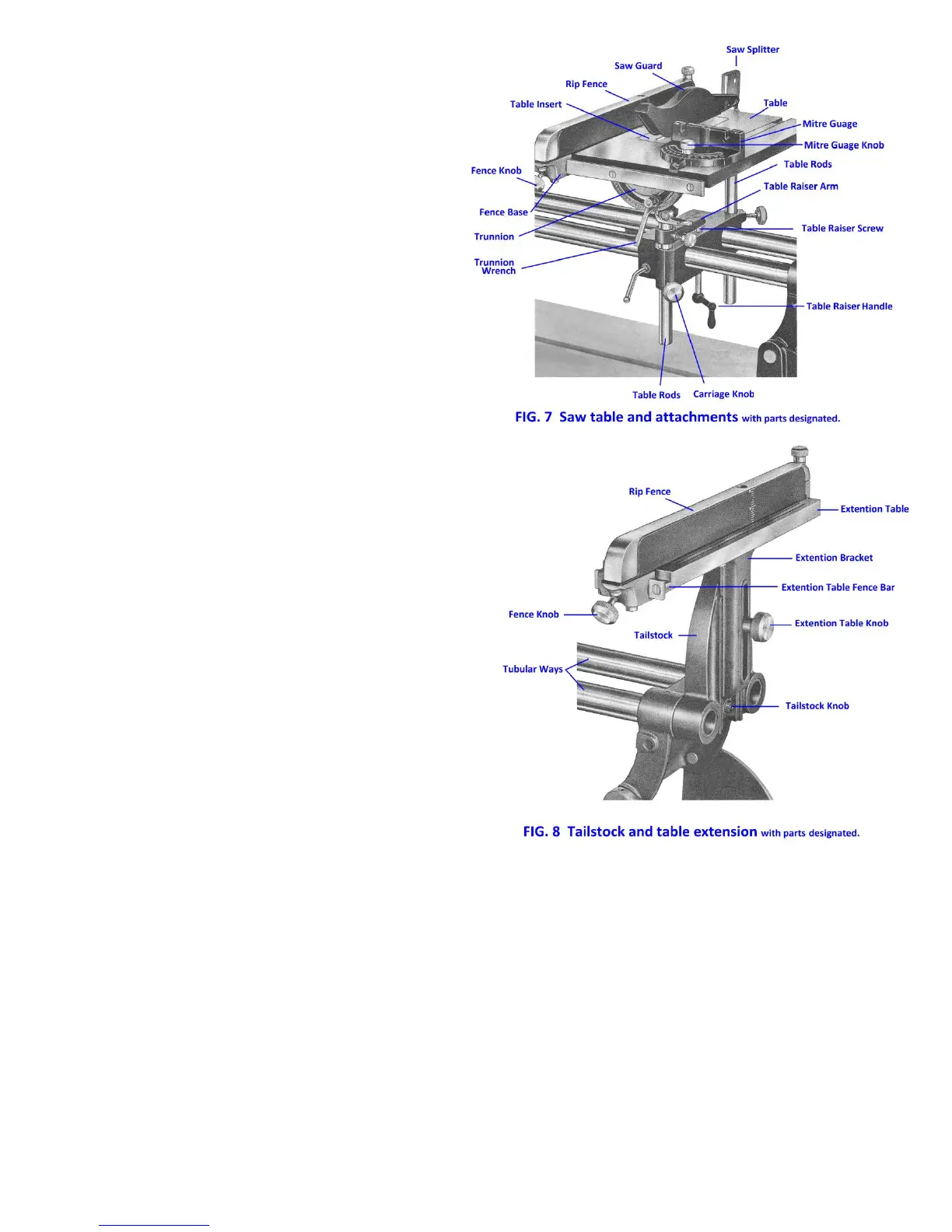

TABLE - Shopsmith's precision finished aluminum table (Fig. 6) is

supported on the carriage by two steel rods, and the adjustment

is held by the carriage knobs. The table can be tilted from 45

degrees in one direction to 90 degrees in the opposite direction.

Shopsmith table can be rapidly raised or lowered, with precision

adjustment by using the table raising screw.

Table trunnion (Fig. 6) permits the table to be tilted and locked at any desired angle. To tilt the table, loosen the trunnion nut with

the trunnion wrench. Then depress the trunnion lever and tilt the table to the desired position. Automatic stops are provided at

the most frequently used positions.

The table insert can be removed to accommodate dado heads and formed cutters if desired. Insert is leveled flush with surface

of the saw table by adjusting Allen screws on under side. Two table slots allow the miter gauge to be used on either side of the

saw blade. The Shopsmith exclusive miter gauge design permits rapid attachment or removal of a miter gauge face extension.

The saw guard and splitter (Fig. 7) combine for a clear view of the work with utmost safety; it can be adjusted to conform to any

position of the table by releasing screw on back of table.

CAUTION: Use the saw guard and splitter for all sawing operations.

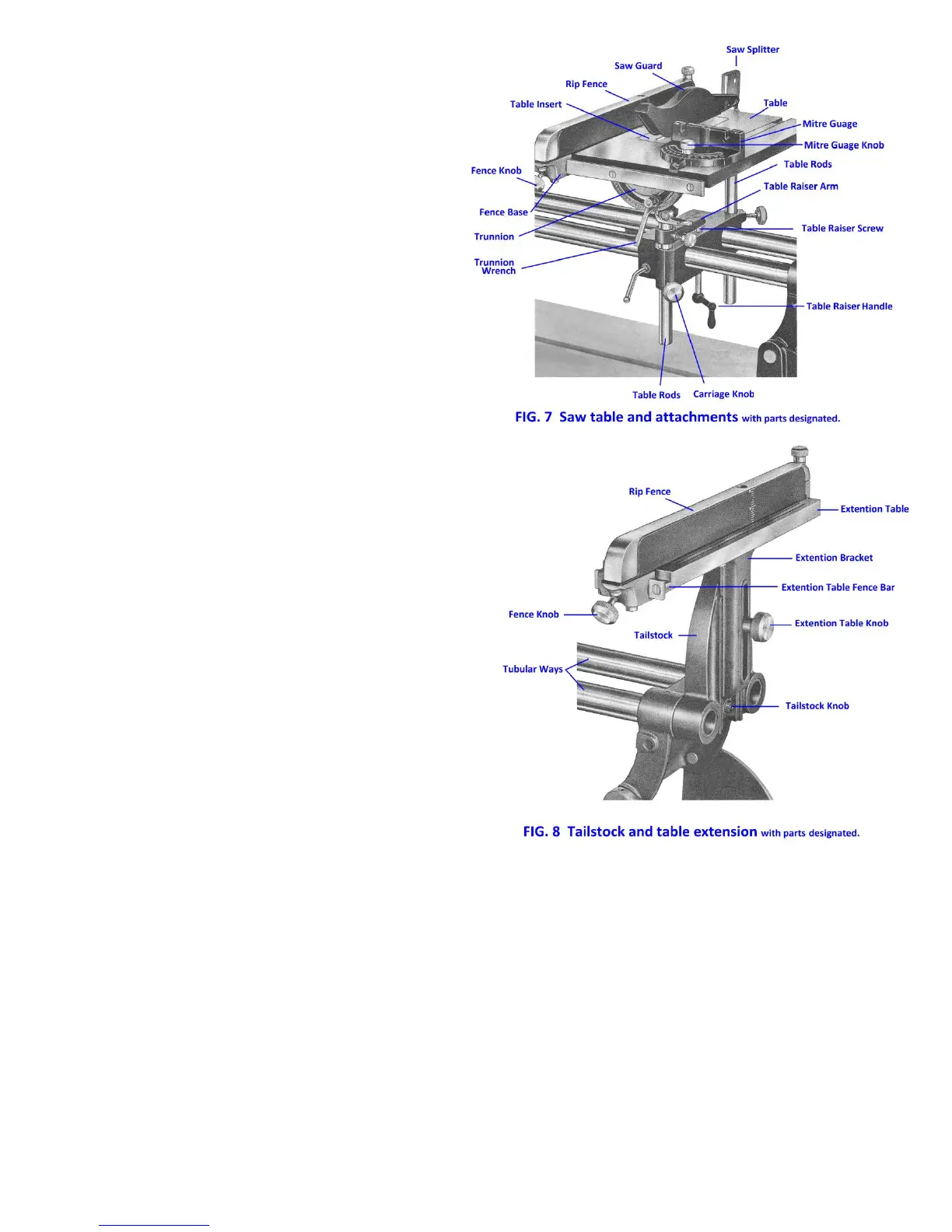

TABLE EXTENSION - The table bracket knob and studscrew holds the table bracket to the tailstock (Fig. 8). The bracket slides up

and down in the machined channel on the back of the tailstock.

Loading...

Loading...