S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 25 of

25

NORMAL MAINTENANCE OPERATIONS

Problem Cause Corrective action

1) Drain leaking

while in service or

on stand-by

Pilot leakage Disconnect alternately connections 2 and 4, see page 15.

If water is leaking from one of the two pressure connections, this means that the relative

pilot has leaks and should be replaced.

If the leakage does not come from the pilot, the cause should be sought, possibly

originating from the head of the V360 piston.

Valve leakage through

the piston system

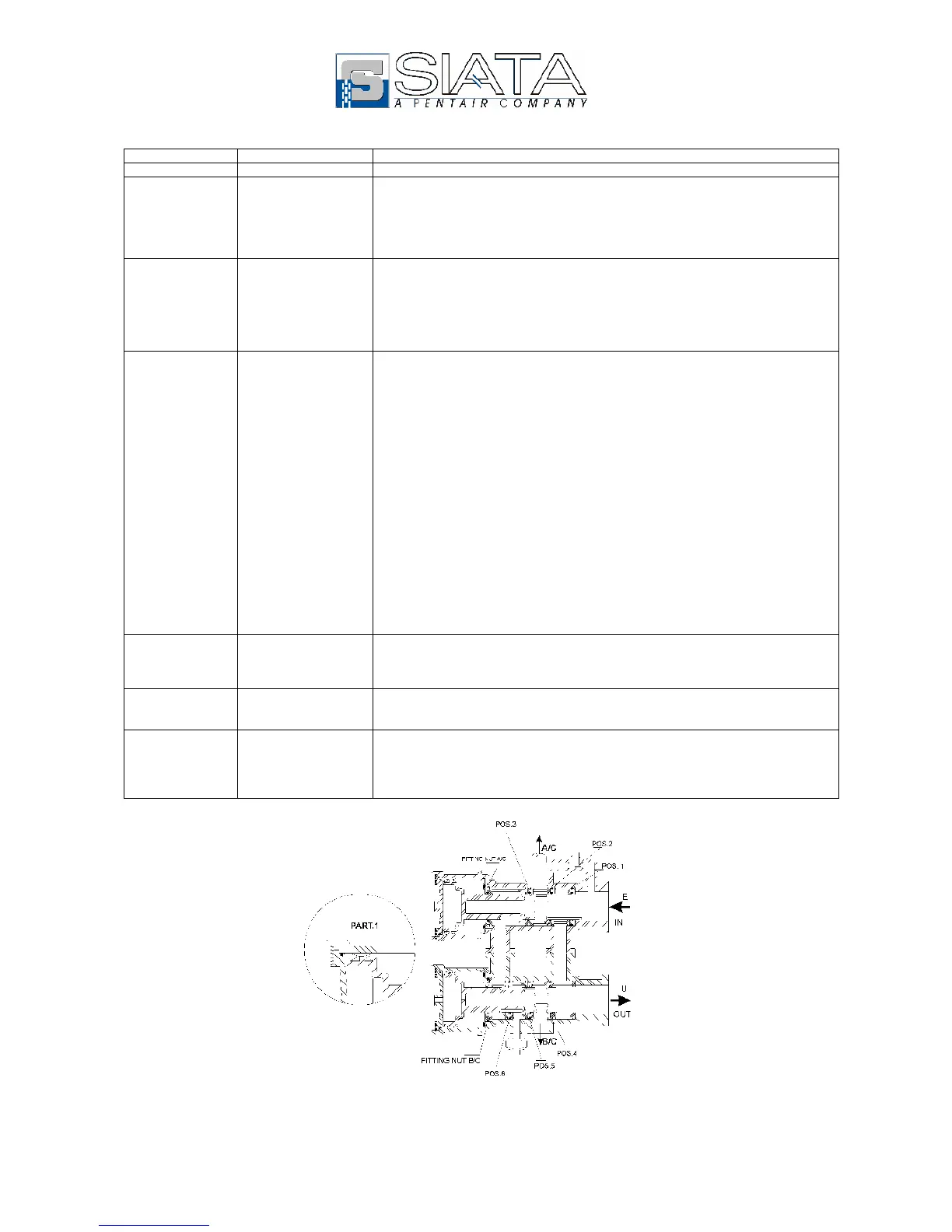

1. Disconnect one by one the connections 1 and 3, see page 15, if the leaking

stops, inspect and if necessary replace the OR of the plastic screw or the

piston if it is ridged

2. Check that the pistons and following Or are undamaged and replace them:

a) First OR after the plastic screw for A/C pos. 3

b) Second OR after the plastic screw for B/C pos. 5

2) Assembly and

disassembly of 2

chambers

Check the internal

surfaces of the

chambers

For all the operations regarding the inside of chambers A/C and B/C the following

procedure should be respected:

A. Turn off the entry water

B. Disconnect the control pipes of the piston movement

C. Remove the seeger ring from the stopper, using a suitable tool

D. Remove the stopper or the relative OR

E. Extract the piston pressing on the internal pin; if it is difficult to extract, loosen the

back flange, to allow air to enter without depressing the piston chamber

F. Remove the ring-nut holding seeger ring

G. Remove the plastic screw and the whole set of distancers and Ors taking care to

reinsert them in the upended piston so as not to lose the correct consequence

H. Check that the inside of the chamber is undamaged

I. Reassemble everything, paying attention to the following:

1) Check that the piston is not scratched and above all that the two DE of the head are

undamaged and positioned correctly (not upended) see PART. 1

2) Check that the two seeger rings are not too out of the shape and when the

seeger is reinserted check that the tool used to insert the seeger is used to support the

expansion of the ring into its position. The seeger stopper should be replaced every

time maintenance is carried out.

See page 22

Hardness leak at

exit

Probable leak between

entry and exit or on

ac/bc seal

Take the piston out of the entry, checking that there is no damage to the surface. If the

piston is damaged, replace it. Otherwise, replace the Ors (pos. 1 and pos. 2) of the

entry chamber. To carry out this operation, proceed as indicated in point 2, paragraphs

“a,b,c,d,e,f”.

Suction failure Injector Disconnect the injector pipe between the injector and the brine. In case of air suction,

the reason of a suction failure have to be searched in the measurement system of the

brine valve.

In case the injector does not suck verify if:

(a) The filter inside the injector body is obstructed

(b) The internal OR are defective or the two injector body are defective (in that case

we suggest to contact SIATA)

(c) The drain conditions do not match with the choosen injector

Loading...

Loading...