Maintenance

9229 9862 176 0D 55

2013-08-28

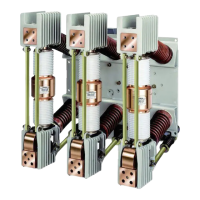

Fig. 68 Maintenance plan

Notes on the maintenance plan:

1) If the vacuum circuit-breaker is operated under unfavourable conditions indoors

(heavy and frequent condensation, dusty air, etc.), we recommend cleaning the

insulating parts and possibly the outer parts of the circuit-breaker at shorter

intervals.

The insulating parts must be clean if their insulating capacity is to be guaran-

teed. Rub insulating parts with a moist cloth.

As a cleaning agent, use only warm water with a mild, liquid household deter-

gent added and leave to dry.

2) Joints and bearings that cannot be disassembled have to be washed out with

detergent prior to work.

3) Lubricant:

No. Work to be done Operating and auxil-

iary materials

Frequency Remarks

annually

every 10,000*

)

every 30,000*

)

after 60,000*

)

*

)

mechanical operating

cycles

3. Operating mechanism

3.1 Exchange motor M1 x Note 4)

3.2 Exchange closing spring x Note 4)

3.3 Replace closing solenoid Y9 x Note 4)

3.4 Replace opening solenoid Y1 x Note 4)

3.5 Replace opening solenoid Y2 x If available,

Note 4)

3.6 Replace undervoltage release Y7 x If available,

Note 4)

3.7 Replace auxiliary switch S1 x

3.8 Replace position switches S3 to S42 x Note 4), note 5)

3.9 Replace closing block x Only for 3AH4305-7,

3AH4305-8, 3AH4306-7,

3AH4306-8,

Note 4)

3.10 Replace opening block x Only for 3AH4305-7,

3AH4305-8, 3AH4306-7,

3AH4306-8,

Note 4)

Bearings, sliding surfaces: Isoflex Topas L32

Bearings and bearings of the auxiliary

switch S1 that are inaccessible in terms of

greasing:

SHELL Tellus Oil 32

Loading...

Loading...