Maintenance

54 9229 9862 176 0D

2013-08-28

Maintenance plan

continued on next page

No. Work to be done Operating and auxil-

iary materials

Frequency Remarks

annually

every 10,000*

)

every 30,000*

)

after 60,000*

)

*

)

mechanical operating

cycles

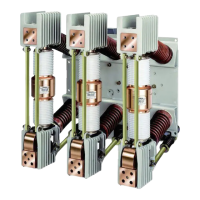

1. Vacuum circuit-breaker

1.1 Clean insulating parts and outer

parts

Warm water, house-

hold cleaners

x Note 1)

1.2 Grease all bearing points and sliding

surfaces as per Fig. 70 and Fig. 69.

Perform 3 to 5 mechanical test

switching operations after greasing

Isoflex Topas L32

Shell Tellus Oil 32

x See Fig. 70 and Fig. 69

Note 2), 3), 6)

1.3 Check all electrical operating materi-

als in the drive for correct functioning

x

1.4 Check line connections for tight seat x

1.5 Check all screw connections and

locking elements for tight fit and

check for completeness

x

2. Pole assembly

2.1 Exchange vacuum interrupters x Possibly depending on the

electrical operating cycle

number as per “Interrupter

service life”,

Note 4)

x Only for 3AH4305-7,

3AH4305-8, 3AH4306-7,

3AH4306-8 maintenance at

the Siemens plant

2.2 Exchange spring guide and insulat-

ing operating rod

x Note 4)

2.3 Angle lever x Only for 3AH4305-7,

3AH4305-8, 3AH4306-7,

3AH4306-8,

Note 4)

Loading...

Loading...