7/11

Siemens Building Technologies CC1N7418en

HVAC Products 08.04.2004

Function

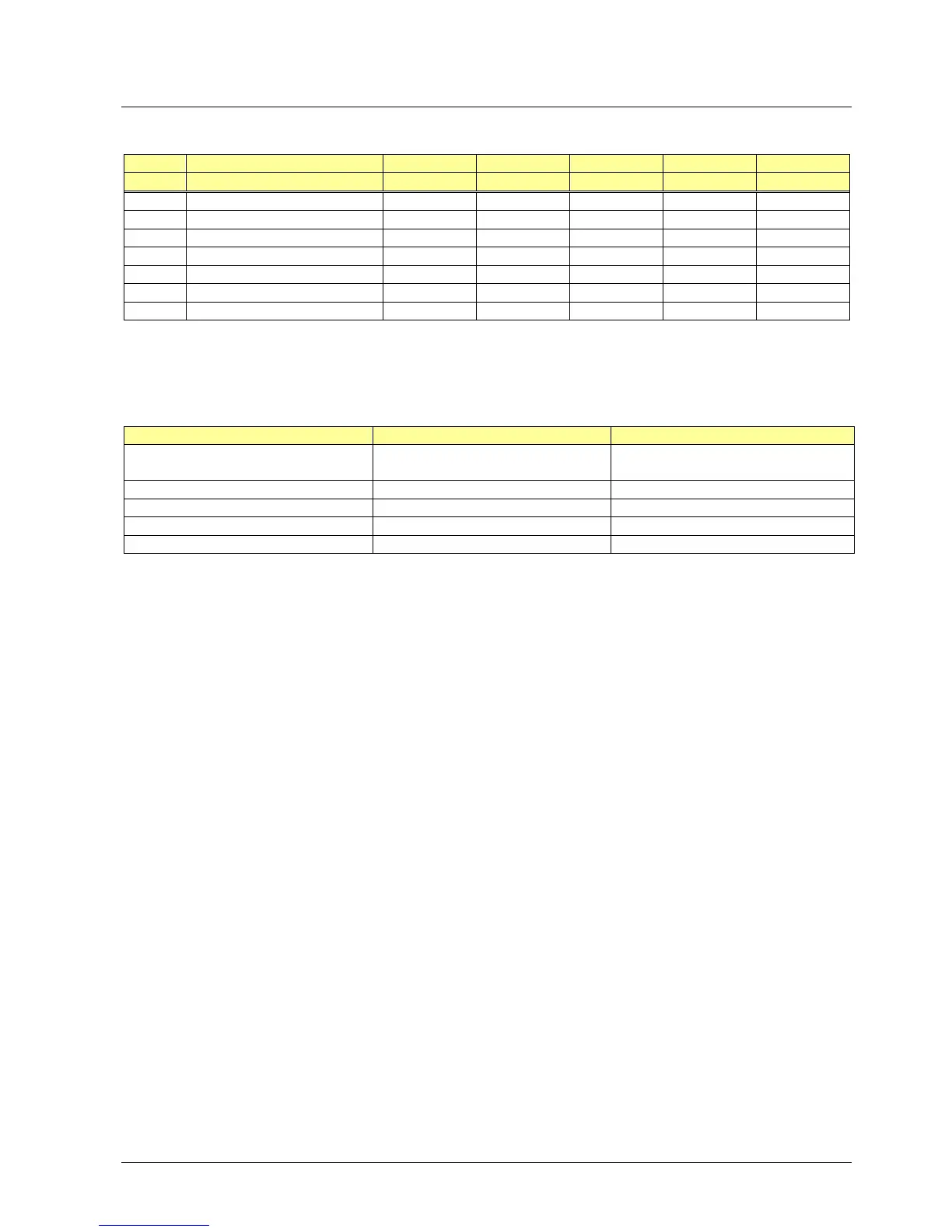

(times in seconds)

1

)

AC 220...240 V LGA41.153A27 LGA41.173A27 LGA52.150B27 LGA52.171B27 LGA63.191A27

AC 100...110 V --- --- LGA52.150B17 --- ---

t1 Prepurge time --- --- approx. 13 approx. 13 approx. 13

t3 Preignition time 15 15 --- --- ---

t3´ Preignition time from start of «TSA» --- --- max. 5 4.5...7.5 max. 10

TSA Ignition safety time 5 10 5 4.5...7.5 10

TSAmax. Max. ignition safety time 10 20 10 20 20

t3n Postignition time max. 2 max. 2 --- --- ---

t4 Interval «BV1 – BV2» approx. 18 approx. 13 approx. 18 approx. 13 approx. 23

¹) All times specified apply to AC 220 V and AC 110 V respectively

For AC 240 V operation, above times are to be multiplied by 0.7

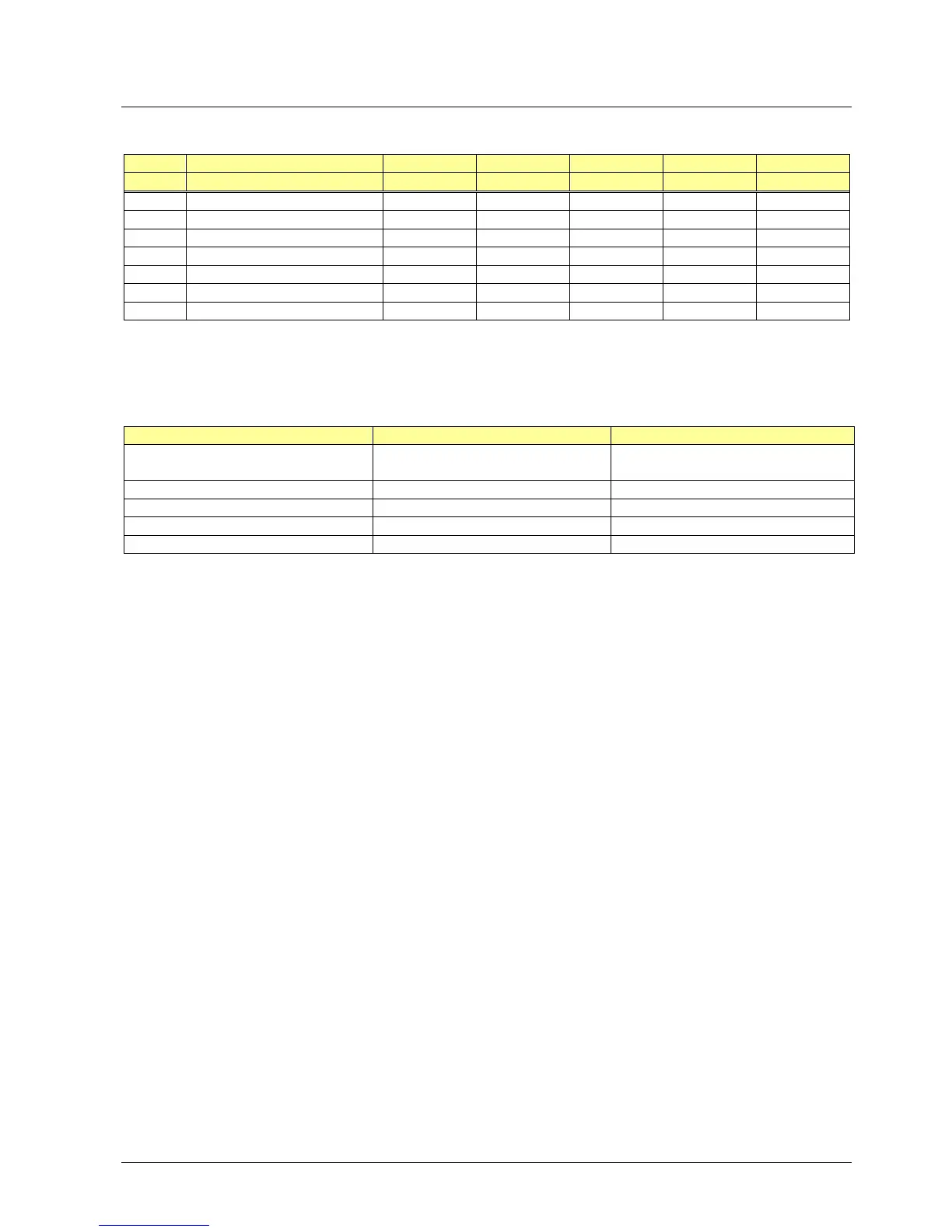

Fault Response of LGA41... Response of LGA52... / LGA63...

Erroneous flame signal during «t1»

or «t3»

Lockout ²) prior to the release of gas Lockout ²) prior to ignition and the re-

lease of gas

No flame on completion of «TSA» Lockout ²) Lockout ²)

Loss of flame during operation Repetition Repetition

No air pressure signal during «t1» --- No start

Air pressure failure during operation --- Shutdown

²)

After lockout, the burner control can be reset after about 60...90 seconds

The conductivity and rectifying effect of hot flame gases are used for flame supervision.

For that purpose, AC voltage is applied to the ionization probe which projects into the

flame.

The current that flows in the presence of a flame (ionization current) generates the

flame signal which is then fed to the input of the flame signal amplifier.

The amplifier is designed such that it only responds to the DC current component of the

flame signal, thus ensuring that a short-circuit between ionization probe and ground

cannot simulate a flame signal (since in that case, AC current would flow).

Control sequence

Control sequence in the

event of fault

Flame supervision with

ionization probe

Loading...

Loading...