Installation

When the test is performed with the

circuit breaker open, the integrity of

the vacuum interrupter will also be

verified. If these levels cannot be

sustained and there is no other source

for the failure, the vacuum interrupter

must be replaced.

Note: The dc test voltage is given as a

reference only. It represents values

believed to be appropriate and

approximately equivalent to the

corresponding power-frequency withstand

test values specified for each voltage

rating. The presence of this column in no

way implies any requirement for a dc

withstand test on ac equipment or that a

dc withstand test represents an acceptable

alternative to ac withstand tests. When

performing dc tests, the voltage should be

raised to the test value in discrete steps

and held for a period of one minute.

Note: Do not use dc high-potential

testers incorporating half-wave

rectification. Such devices produce high

peak voltages.

These high voltages will produce X-ray

radiation. Such devices also show

erroneous readings of leakage current

when testing vacuum circuit breakers.

Field dielectric tests are recommended

when new units are installed, or after

major field modifications. The

equipment should be put in good

condition prior to the field test. It is not

expected that equipment shall be

subjected to these tests after it has

been stored for long periods of time or

has accumulated a large amount of

dust, moisture or other contaminants

without being first restored to good

condition.

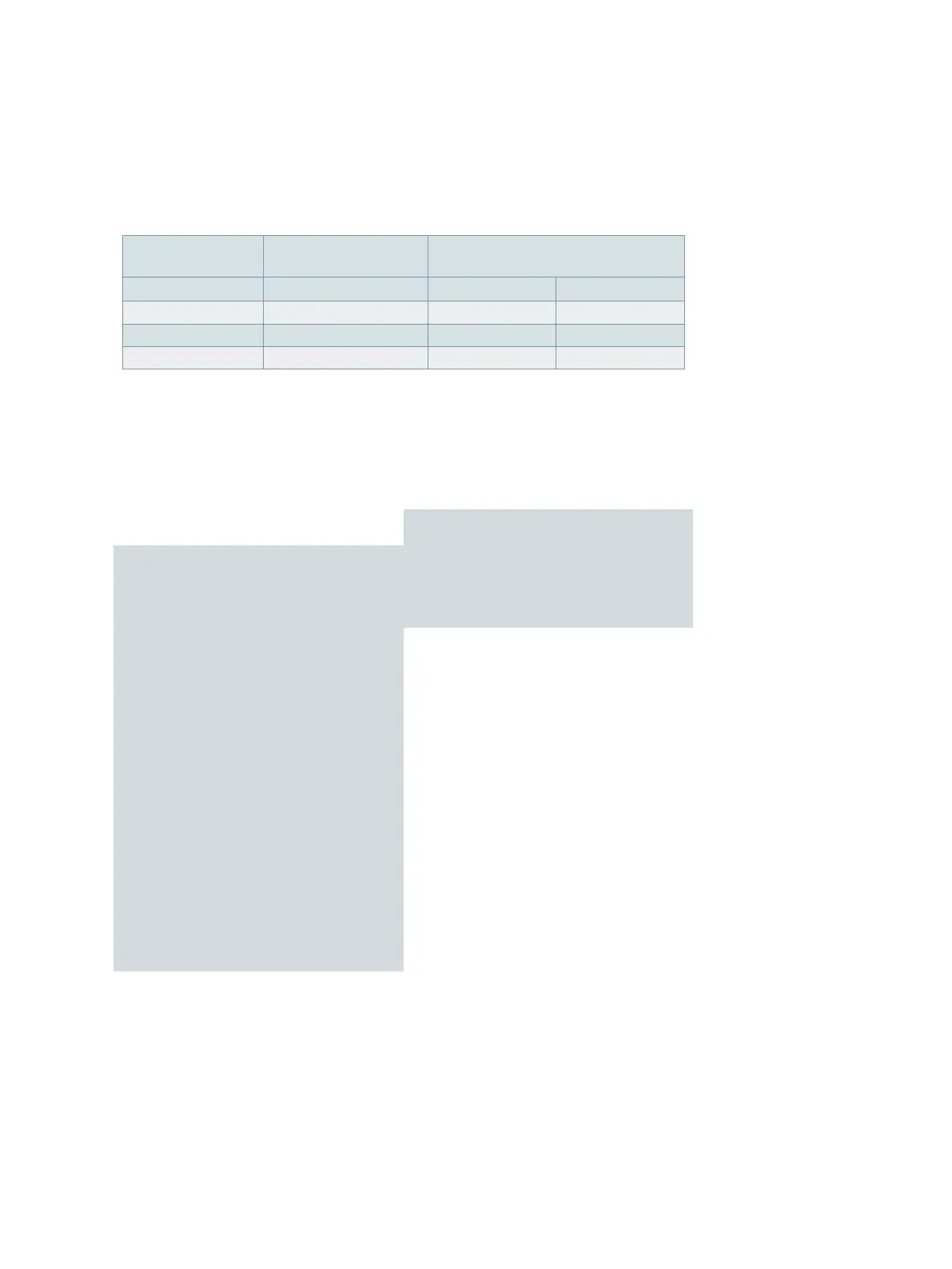

Rated maximum

voltage

Rated power-

frequency withstand

Field-test voltage

kV (rms) kV (rms) kV (rms) kV dc

15.5 50 37.5 53

27.6 60 45 64

38.0 80 60 85

Table 2: High-potential test voltages

A dielectric test on secondary and

control circuits should be made for one

minute at 1,125 volts ac or 1,590 volts

dc. The above voltages are in

accordance with NEMA Standards.

Note: Certain control devices, such as

motors and motor circuits, should be

tested at 675 volts ac. Electronic devices

should be tested at the voltages specified

in the instruction manual for the electronic

device.

3. Charge the closing springs manually

and push the close pushbutton to close

the circuit breaker.

4. Verify main contact status indicator

shows CLOSE. Press the trip

pushbutton and verify the main

contact status indicator shows OPEN.

The spring condition indicator should

also show DISCHARGED.

5. Energize the control circuits. The motor

should run to charge the closing

springs, and then automatically turn

off.

6. Close the circuit breaker electrically

(locally and remotely as applicable)

and verify the circuit breaker shows

CLOSE and remains closed by checking

the main contact status indicator. Note

that the motor will immediately run to

recharge the closing springs.

7. Trip the circuit breaker electrically

(locally and remotely as applicable).

8. Trip the circuit breaker by passing

sufficient current (or voltage if

applicable) through the coils of

protective relays.

23

Loading...

Loading...