62

Definition Boxes and The High-Speed Counter Definition (HDEF) instruction assigns

High-Speed Counters the operating mode to a specific high-speed counter (HSCx).

The mode selection defines the clock, direction, start, and

reset functions of the high-speed counter. High-speed counters

can be defined by the definition box to operate in any of the

12 available modes. Not all counters can operate in all of the

available modes, however. Refer to the S7-200 System Manual

for definitions available for each counter.

The High-Speed Counter (HSC) instruction configures and

controls a specific high-speed counter based upon the state of

the special HSC bits. The N parameter specifies the high-speed

counter number. Each counter has dedicated inputs for clocks,

direction control, reset, and start, where these functions are

supported.

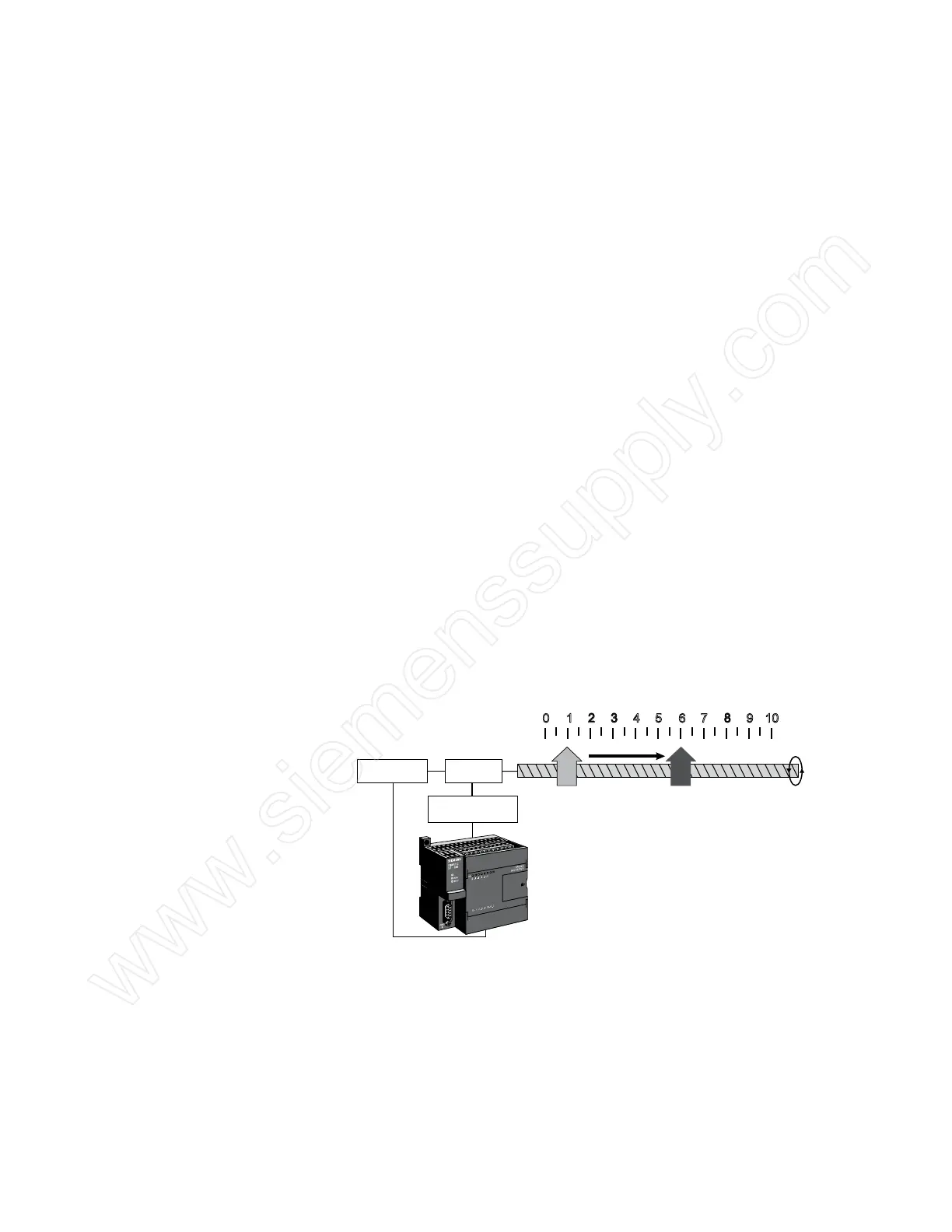

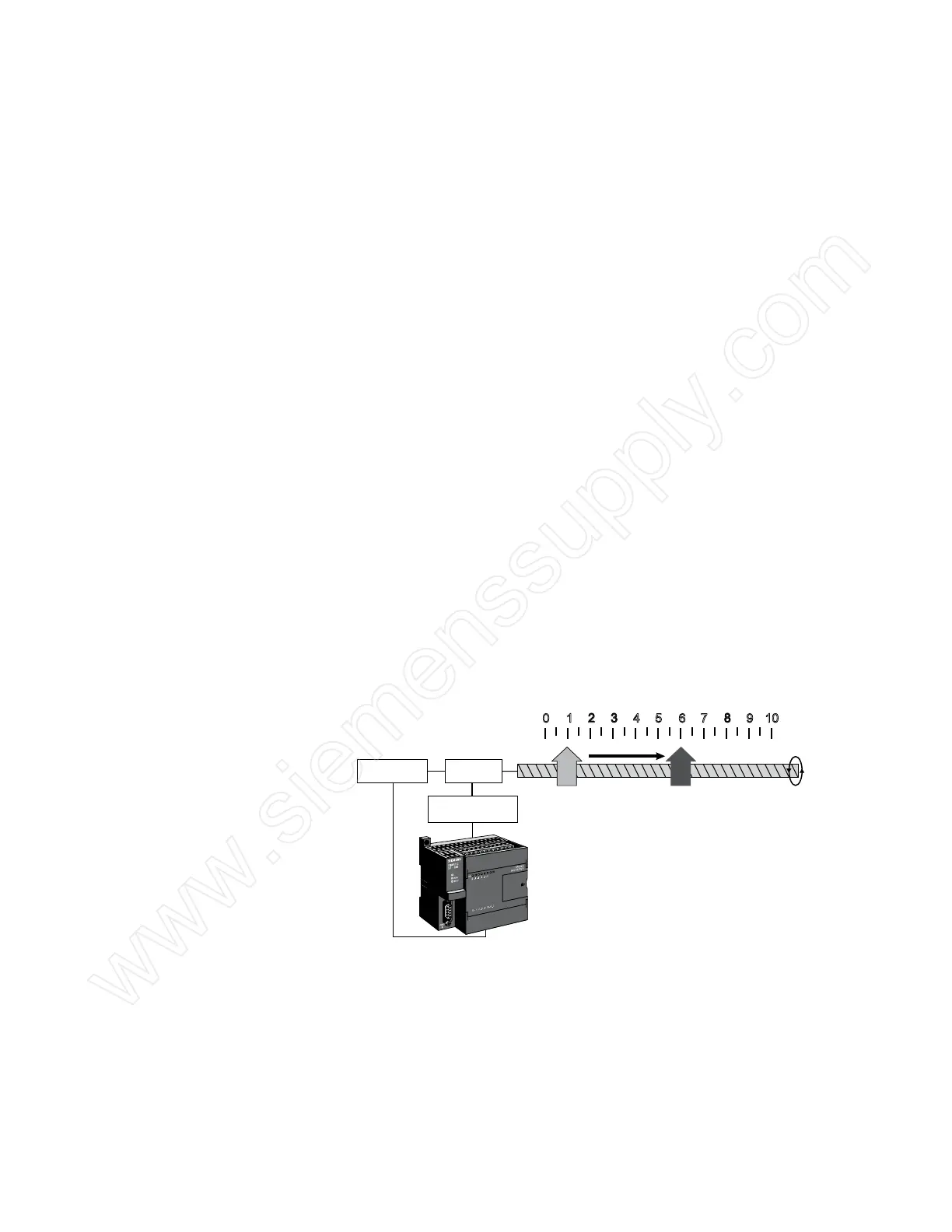

Positioning Example Positioning is one example of an application that may require

use of a high-speed counter. In the following illustration, two

PLC discrete outputs (one for forward and one for reverse)

control a reversing motor starter, which, in turn, controls a

motor.

The motor shaft is connected to an encoder and to a positioning

screw. A platform mounted on the positioning screw moves

away from position 0 as the motor turns in the forward direction

and towards position 0 as the motor turns in the reverse

direction. Pulses from the encoder are connected to PLC inputs

associated with a high speed counter.

1 2 3 4 5 6 7 8 9 100

Encoder

Motor

Reversing

Motor Starter

SF/DIAG

212-1BB

23-0XB0

In this example, the high-speed counter is programmed to

move the platform from position 1 to position 6 and later to

return to position 1. These positions could be associated with

manufacturing operations performed on a part mounted on the

platform.

Loading...

Loading...