6

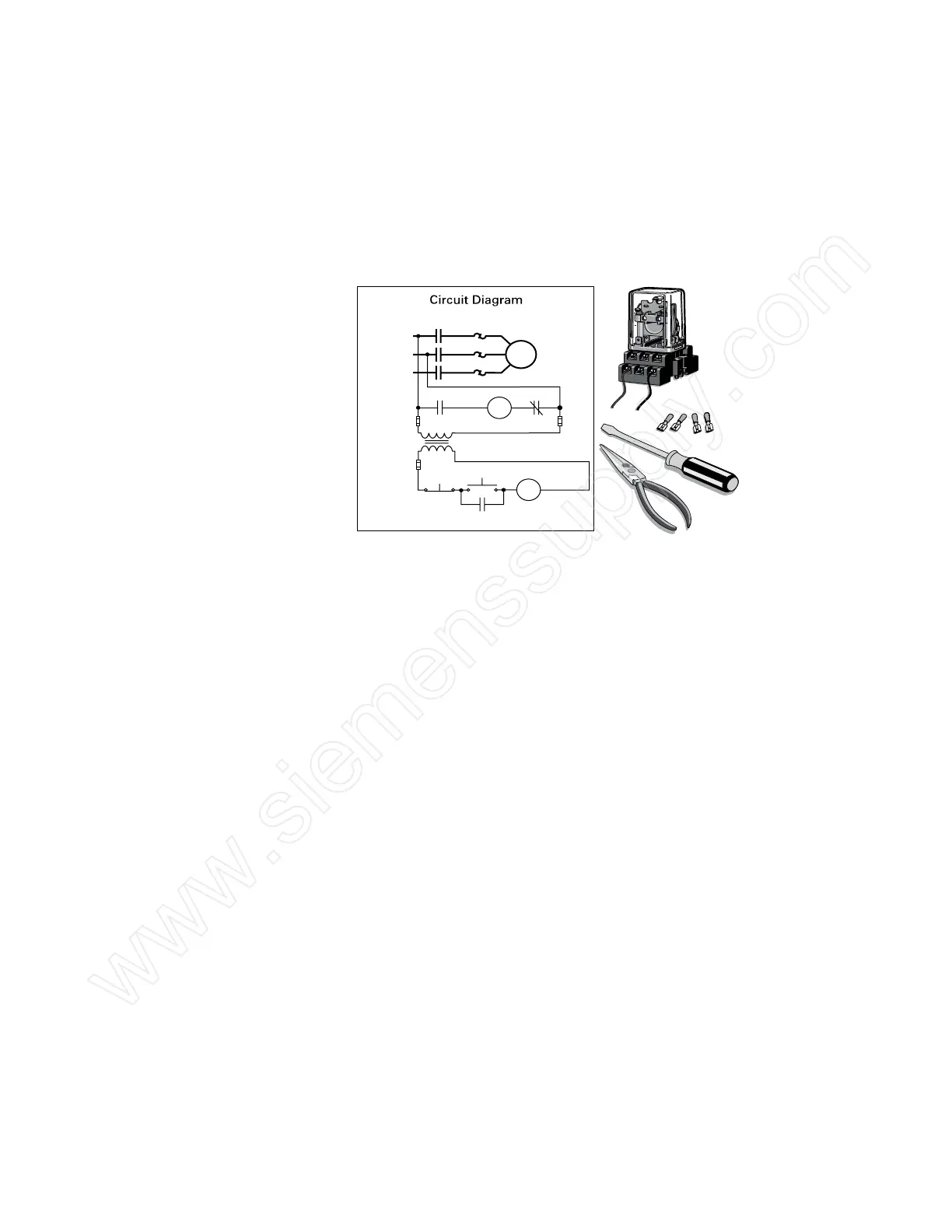

Hard-Wired Control Prior to PLCs, many control tasks were performed by

contactors, control relays, and other electromechanical devices.

This is often referred to as

hard-wired control. Circuit

diagrams had to be designed, electrical components specified

and installed, and wiring lists created. Electricians would then

wire the components necessary to perform a specific task. If

an error was made, the wires had to be reconnected correctly.

A change in function or system expansion required extensive

component changes and rewiring.

OL

M

CR

CR

L1

T1

T2

T3

L2

L3

OL

OL

OL

M

M

CR

M

Motor

Start

Stop

460 VAC

24 VAC

1

2

Advantages of PLCs PLCs not only are capable of performing the same tasks as

hard-wired control, but are also capable of many more complex

applications. In addition, the PLC program and electronic

communication lines replace much of the interconnecting wires

required by hard-wired control. Therefore, hard-wiring, though

still required to connect field devices, is less intensive. This also

makes correcting errors and modifying the application easier.

Some of the additional advantages of PLCs are as follows:

• Smaller physical size than hard-wire solutions.

• Easier and faster to make changes.

• PLCs have integrated diagnostics and override functions.

• Diagnostics are centrally available.

• Applications can be immediately documented.

• Applications can be duplicated faster and less expensively.

Siemens Modular PLCs Siemens SIMATIC PLCs are the foundation upon which our

Totally Integrated Automation (TIA) concept is based.

Because the needs of end users and machine builders vary

widely, SIMATIC PLCs are available as conventional modular

controllers, embedded automation products, or as PC-based

controllers.

Loading...

Loading...