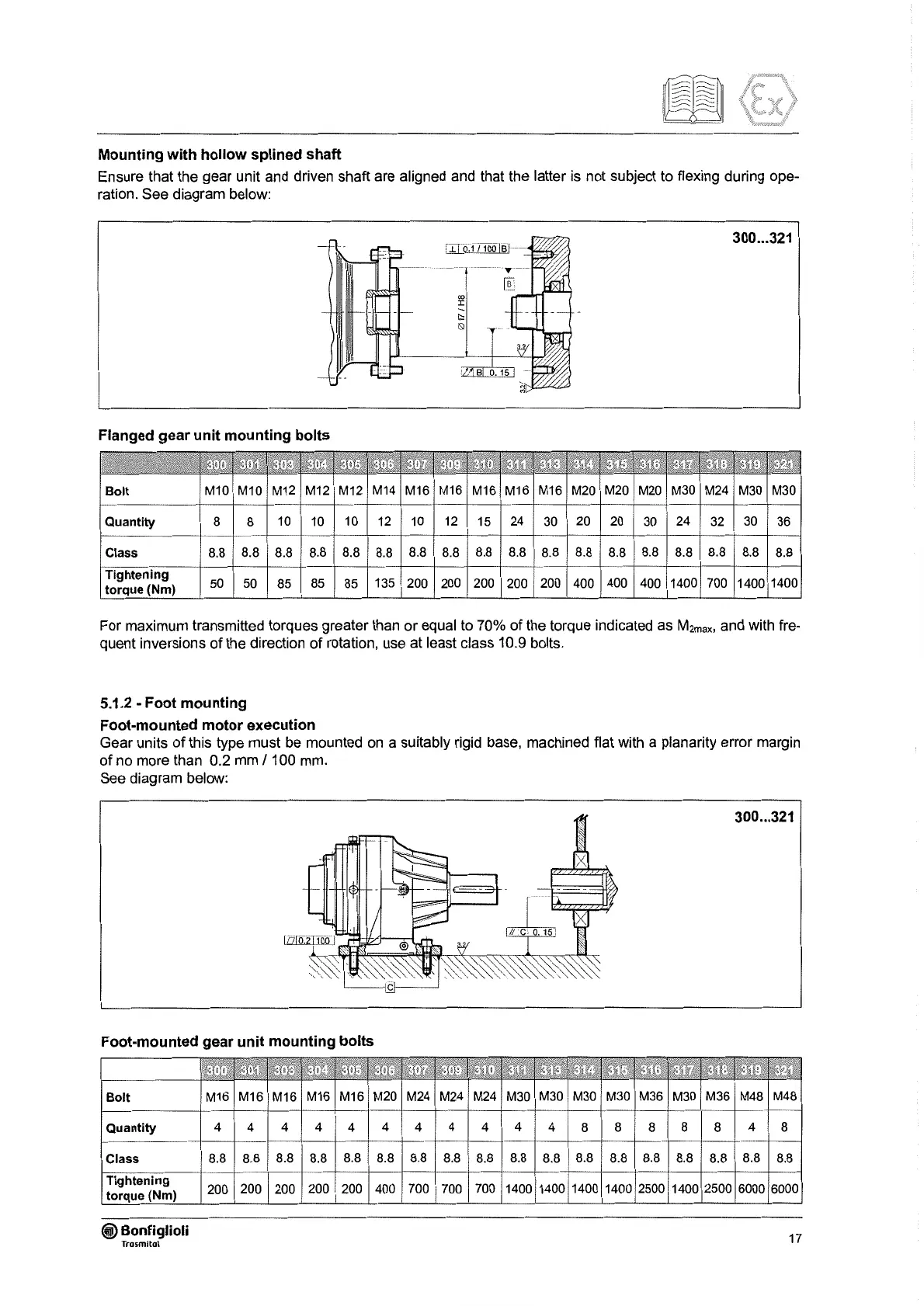

Mounting

with

hollow

splined

shaft

Ensure that the gear unit and driven shaft are aligned and that the latter

is

not subject to flexing during ope-

ration. See diagram below:

Flanged

gear

unit

mounting

bolts

Bolt

M10 M10 M12 M12

M12

Quantity 8 8

10

10 10

Class 8.8 8.8

8.8 8.8 8.8

Tightening

50 50 85

85 85

torque (Nm)

M14 M16

12

10

8.8

8.8

135

200

>J:Jo.1

TToolBI--

ro

I:

I:::

0

M16

12

8.8

200

M16 M16

15 24

8.8 8.8

200 200

300 ...

321

M16 M20 M20 M20 M30 M24 M30

M30

30 20 20 30

24 32

30 36

8.8 8.8

8.8 8.8 8.8

8.8 8.8 8.8

200

400 400 400

1400

700

1400 1400

For maximum transmitted torques greater than or equal to 70% of the torque indicated as M2max. and with fre-

quent inversions of the direction of rotation, use at least class 10.9 bolts.

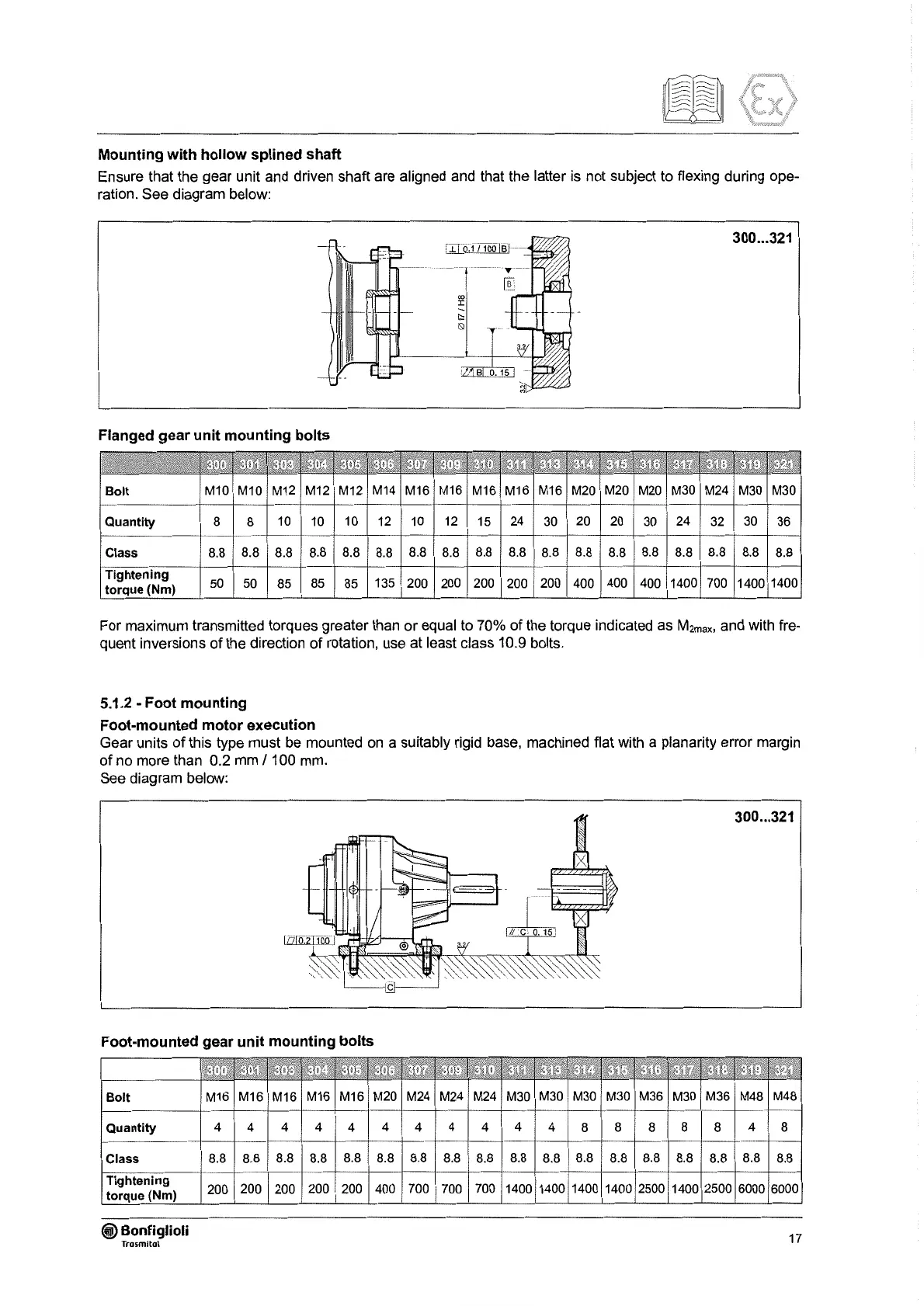

5.1.2 -

Foot

mounting

Foot-mounted

motor

execution

Gear units of this type must be mounted

on

a suitably rigid base, machined flat with a planarity error margin

of no more than 0.2 mm

I 100

mm.

See diagram below:

300".321

Foot-mounted gear

unit

mounting

bolts

Bolt

M16 M16 M16 M16

M16 M20 M24 M24 M24 M30 M30 M30 M30 M36 M30 M36 M48 M48

Quantity

4 4 4

4 4

4 4

4 4 4 4 8 8 8 8

8

4 8

Class

8.8 8.8

8.8 8.8 8.8

8.8 8.8 8.8

8.8 8.8 8.8

8.8 8.8 8.8 8.8 8.8

8.8 8.8

Tightening

200

200

200 200

200 400 700 700 700 1400 1400 1400 1400 2500 1400 2500 6000 6000

torque (Nm)

@ Bonfiglioli

17

Trosmitol

Loading...

Loading...