5.1.3 - Shaft mounting

Mount the torque

arm

with bolts

of

at least class 8.8 tightened to a torque of 70% of their failure stress. Clean

and

degrease both the internal coupling surface of the gear unit shaft

and

the external coupling surface of

the machine's driven shaft.

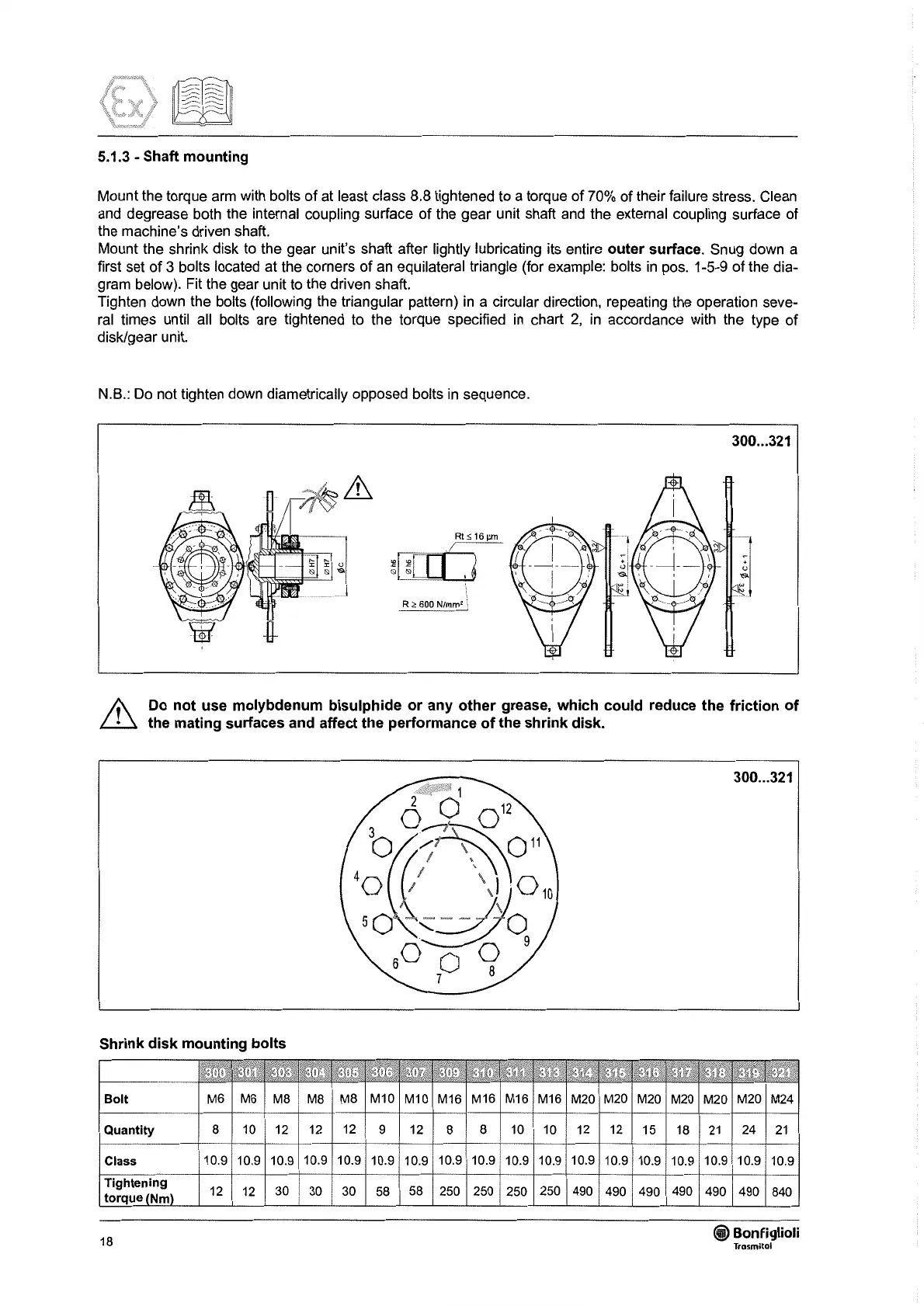

Mount the shrink disk to the gear unit's shaft atter lightly lubricating its entire

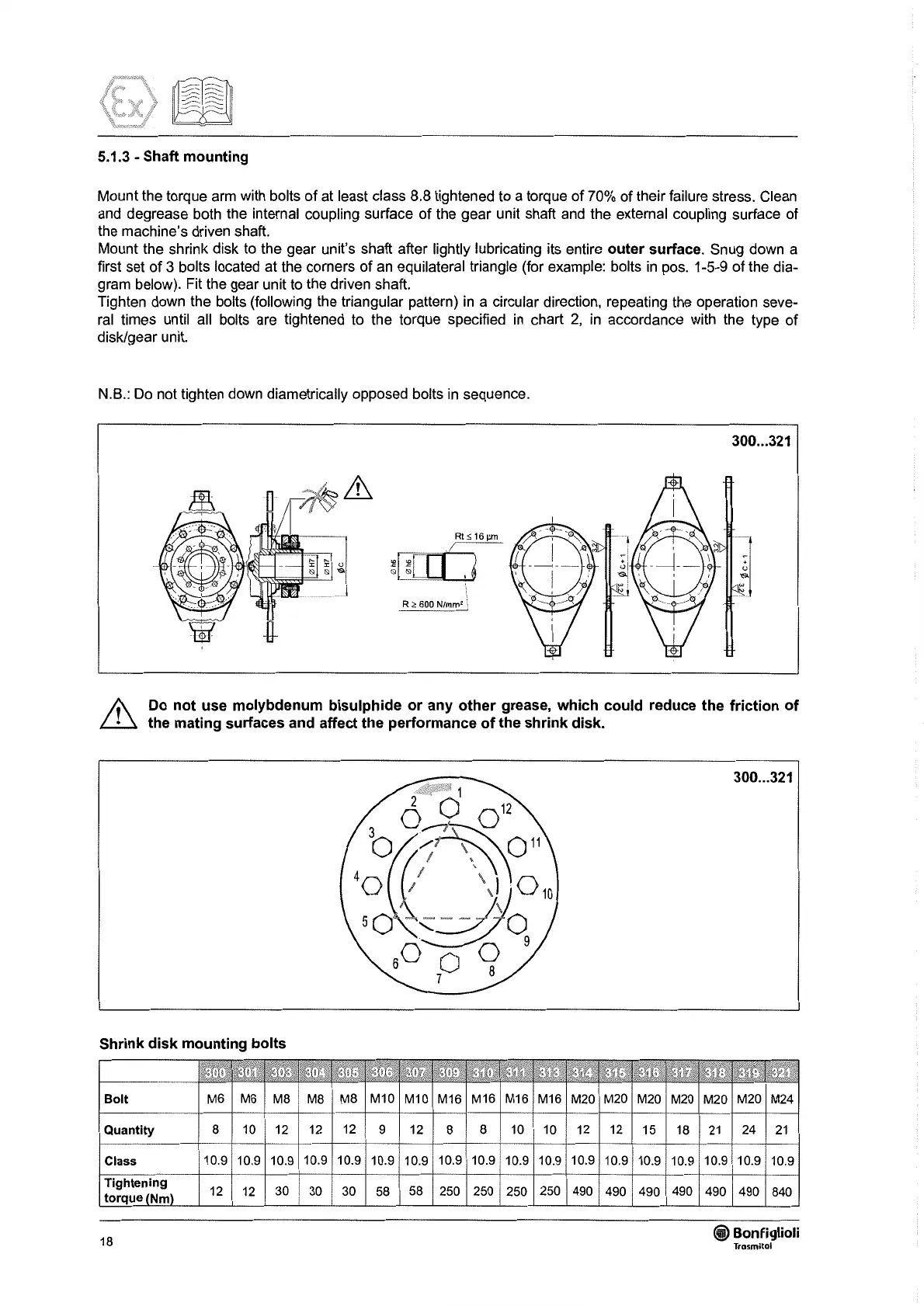

outer surface. Snug down a

first set of 3 bolts located at the corners of

an

equilateral triangle (for example: bolts

in

pos. 1-5-9

of

the dia-

gram below). Fit the gear unit to the driven shaft.

Tighten down the bolts (foliowing the triangular pattern)

in

a circular direction, repeating the operation seve-

ral

times until

all

bolts are tightened to the torque specified in chart

2,

in

accordance with the type of

disk/gear unit.

N.B.: Do not tighten down diametrically opposed bolts

in

sequence.

300

...

321

Rt516

µm

~[ ~l

I I J

R;,

600 N/mm

2

:

Do

not

use molybdenum bisulphide

or

any

other

grease, which could reduce the friction

of

the mating surfaces and affect the performance

of

the shrink disk.

300

...

321

Shrink

disk

mounting bolts

Bolt

M6 M6

MS MS MS

M10

M10

M16

M16

M16

M16 M20 M20 M20

M20 M20 M20 M24

Quantity s

10 12 12 12 9 12 s

s

10 10 12

12

15

1S

21

24

21

Class

10.9 10.9 10.9 10.9 10.9 10.9 10.9 10.9 10.9 10.9 10.9 10.9

10.9

10.9

10.9

10.9

10.9 10.9

Tightening

12

12

30 30 30

5S

5S

250

250 250 250 490 490 490

490 490 490

S40

torque

Nm

1S

@ Bonfiglioli

Trosmitol

Loading...

Loading...