6/26

Building Technologies Division CC1N7817en

24.02.2015

Mechanical design

Lower housing part made of die-cast aluminum

Housing cover made of impact-proof and heat-resistant plastic

Synchronous motor

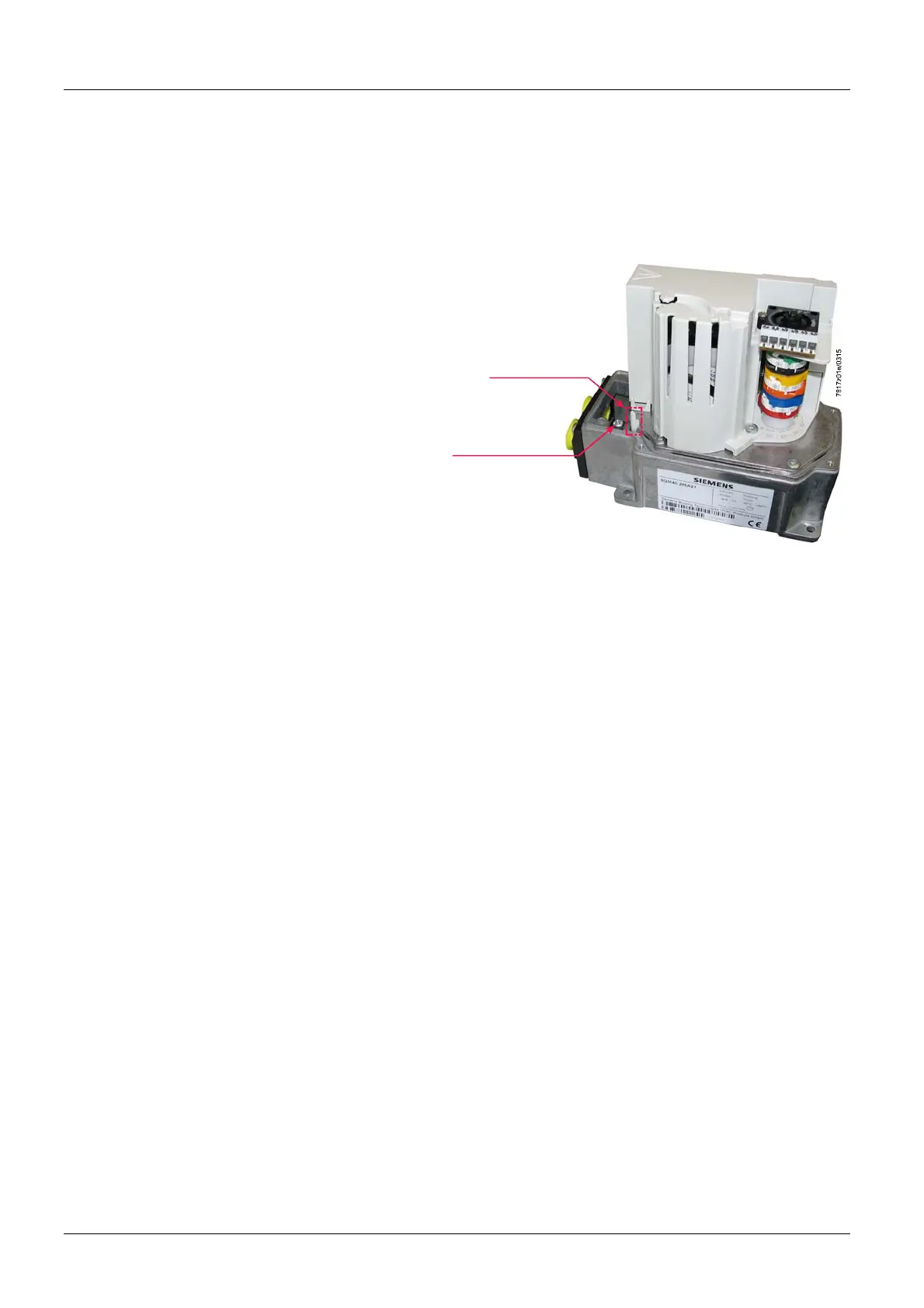

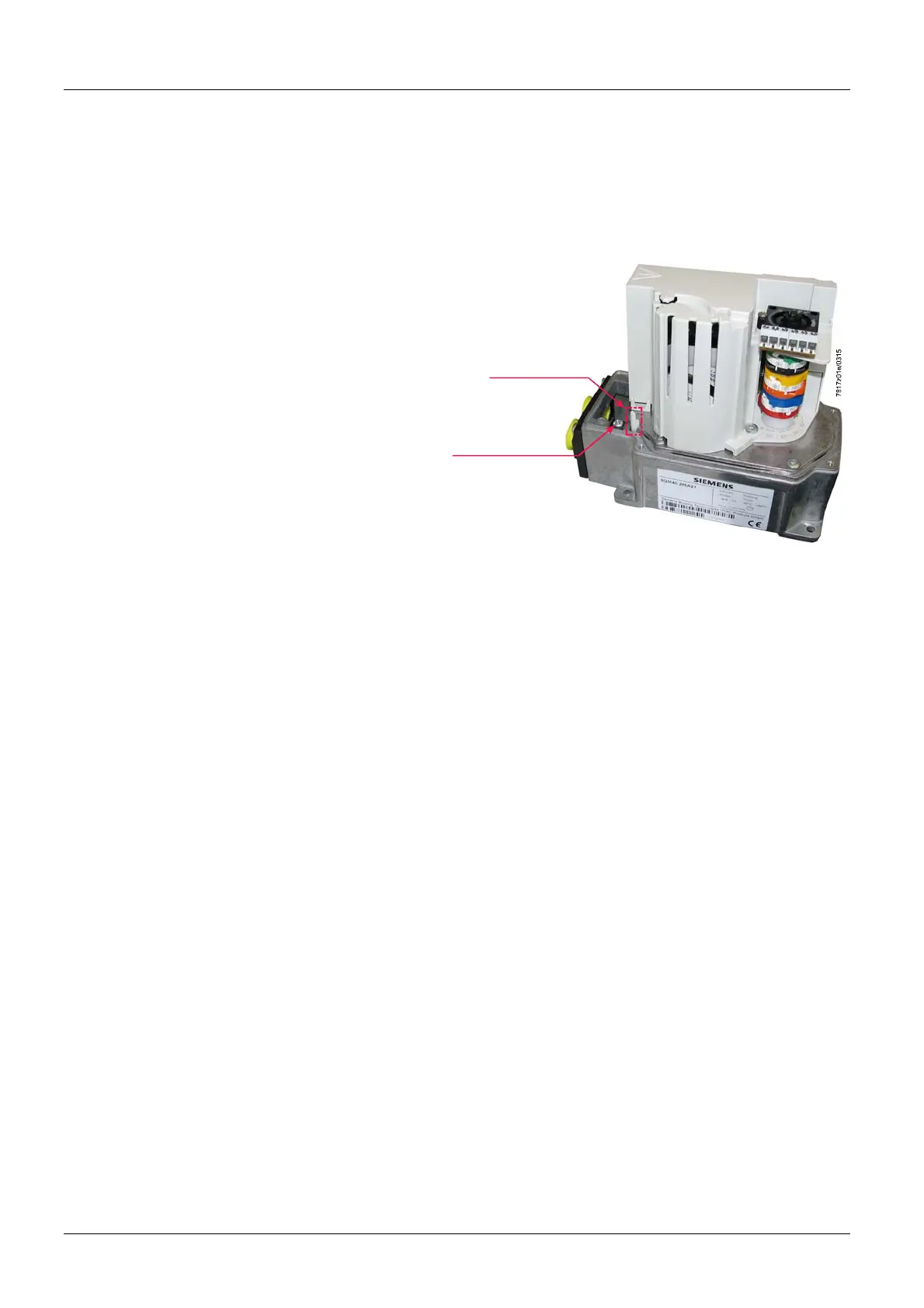

Shaft can be manually disengaged from the motor by operating the coupling

(coupling pin (K1))

Automatic reengagement

Disengagement of drive shaft / motor by pressing coupling pin «K1»

Coupling pin "K1"

Earth terminal „PE“

Earth terminal (PE) with screw fitting

Non-reactive gear

With adjustable cams

Scales beside the cams indicate the angle of the switching point

Internally

– Scale 0...135° at the end of the cam assembly

– Scale range to direction of rotation with arrow marking for SQM41 or with marking

in slot die for SQM40

RAST3.5 screw terminals are factory supplied, depending on the PCB variant

RAST5 screw terminals are factory supplied, depending on the PCB variant

Optional: Insulation displacement connectors

Cable entry by means of 2 openings in the connector cover supplied.

The cable glands are not included in the scope of delivery

Large openings in the housing allow easy cable installation

Maintenance-free gearwheels and bearings.

Different shaft versions available, shafts are supplied assembled

Drive shaft is not replaceable

Mounting holes on the lower side of the housing (shaft side), such as actuators

SQM45... / SQM48... using M5 screws, or alternatively as actuators SQM10... / SQM20...

front mounting using M5 self-tapping screws (see chapter Dimensions).

Housing

Drive motor

Coupling

Earthing connection

Cam shaft drive

djustment of

switching points

Position indicator

Electrical

connections

Gear train

Drive shaft

ctuator fixing

Loading...

Loading...