8 MSK5000+MB500+MR500 Datum 21.09.2010 Art.Nr. 83109 Änd. Stand 318/10

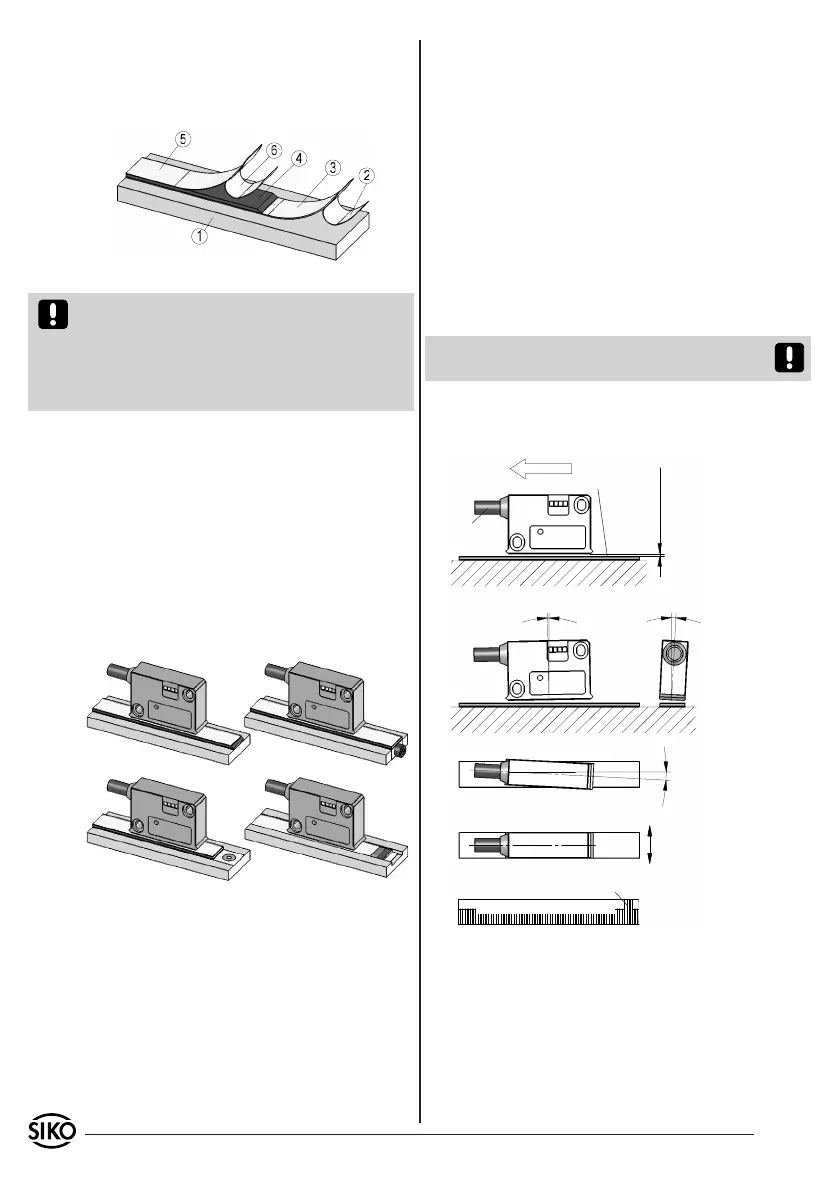

Fig. 1: Mounting of the magnetic strip

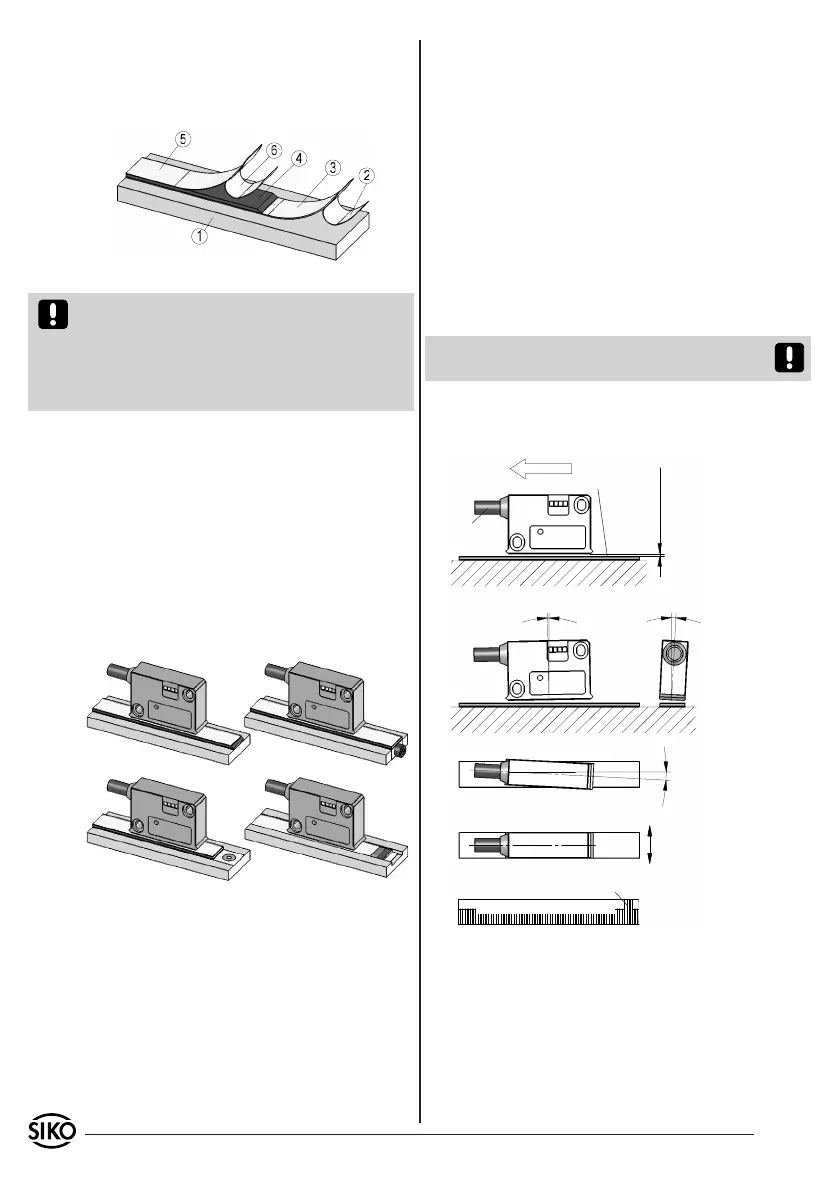

Fig. 2 Fig. 3

Fig. 4 Fig. 5

0.1mm ... 2.0mm wit-

hout reference point

0.1mm ... 1.5mm with

reference point

Gap sensor/magnetic strip

Maximum alignment error

active side

Direction of

outgoing cable

Travel direction

Signal

A before B

Position of the reference point relating

to the marking on the magnetic strip.

Admissable deviatoion

middle of tape/sensor:

without ref. point ±2mm

with ref. point ±0.5mm

< 1°

< 3°

< 3°

MBxxxx GEK WT RP NNNNNN

Fix cover strip (both ends should slightly over-

lap).

Also fix cover strip's ends to avoid unintenti-

onal peeling.

•

•

3.3 Mounting of the magnetic sensor MSK5000

The magnetic sensor MSK5000 can be fastened by

using two bolts M3 over the elongated holes. We

recommend to use the enclosed fixing screws and

washer springs (fastening torque design K=0,25Nm,

design M+AM=1Nm).

Cables should be layed in such a way that there

is no danger of damaging. Provide tension relief

and drag chain or casing, if necessary.

Observe the correct alignment with regard

to the counting direction (fig. 6 and 7). This

does not apply if the counting direction can be

reversed in the electronic interpretation (e.g. in

SIKO's magnetic-strip displays).

Attention! The tolerance and gap measures must

be observed over the whole measuring length.

LINEAR application MSK5000 with MB500:

•

•

Attention! Do not expose the system to magne-

tic fields. Any direct contact of the magnetic strip

with magnetic fields (e.g. adhesive magnets or

other permanent magnets) is to be avoided. Sen-

sor movements during power loss are not captured

by the follower electronics.

Mounting examples

Mounting with chamfered ends (fig. 2) is not re-

commended unless the strip is installed in a safe

and protected place without environmental influ-

ences. In less protected mounting places the strip

may peel. There we recommend mounting accord.

to fig. 3 and 4.

Mounting in a groove (fig. 5) best protects the

magnetic strip. The groove should be deep enough

to totally embed the magnetic strip.

3.2 Mounting of the magnetic ring MR500

Slide magnetic ring MR500 onto the shaft and

then tighten grub screw M6 to fix it to the shaft.

Ensure sliding fit between shaft and MR500.

Mount MR500 without force and without strain.

Possible forces should go to the metal flange.

Avoid knocks on the magnetic ring.

Provide for a relief groove in the solid shaft

(see fig. 7).

•

•

•

Loading...

Loading...