MSK5000+MB500+MR500 Datum 21.09.2010 Art.Nr. 83109 Änd. Stand 318/10 7

MSK5000

MB500

MR500

ENGLISH

Exemplary sensor illustrations are valid for all sen-

sor types unless described separately.

1. Warranty information

In order to carry out installation correctly, we

strongly recommend this document is read very

carefully. This will ensure your own safety and

the operating reliability of the device.

Your device has been quality controlled, tested

and is ready for use. Please observe all warnings

and information which are marked either directly

on the device or specified in this document.

Warranty can only be claimed for components

supplied by SIKO GmbH. If the system is used

together with other products, there is no warranty

for the complete system.

Repairs should be carried out only at our works.

If any information is missing or unclear, please

contact the SIKO sales staff.

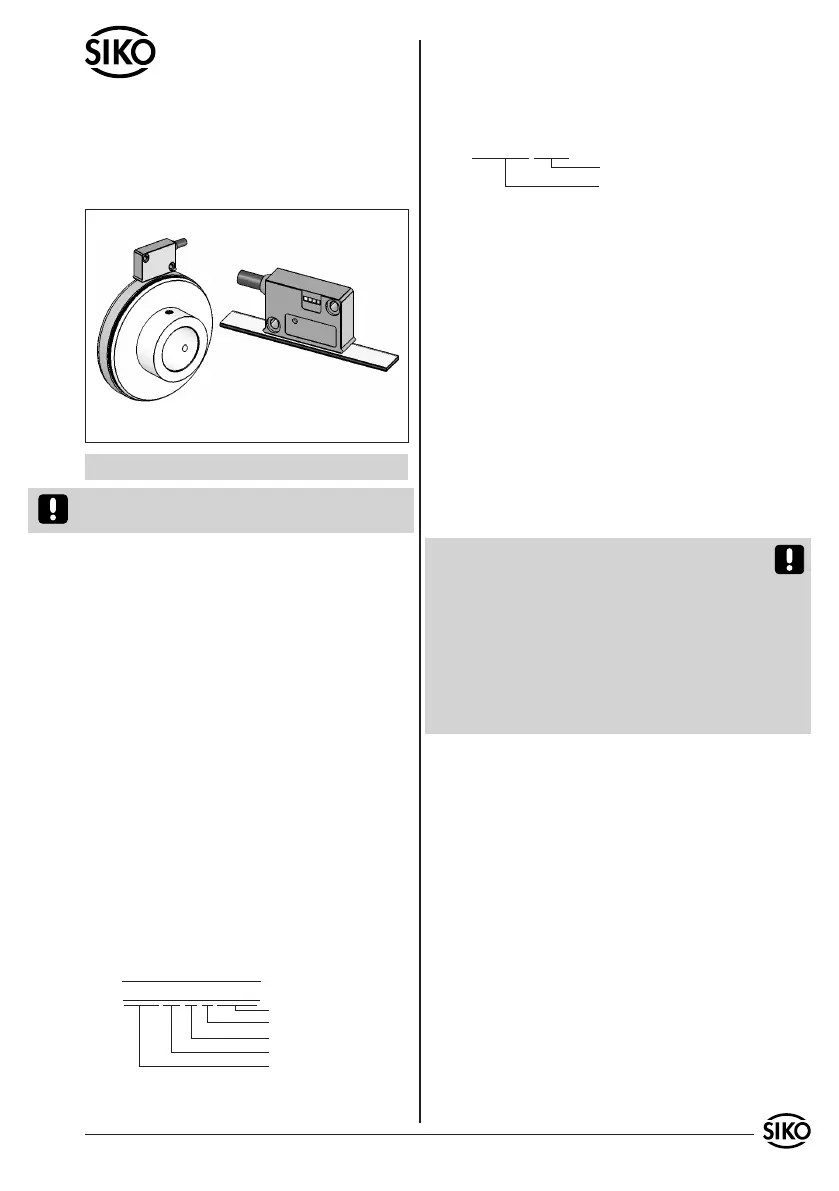

2. Identification

Magnetic strip: identification by printing on the

strip.

•

•

•

•

Magnetic sensor, magnetic ring: Please check

the particular type of unit and type number from

the identification plate. Type number and the cor-

responding version are indicated in the delivery

documentation.

e.g. XXXXXXX-0023

version number

type of unit

3. Installation

For mounting, the degree of protection specified

must be observed. If necessary, protect the unit

against environmental influences such as sprayed

water, dust, knocks, extreme temperatures.

3.1 Mounting the magnetic strip

The mounting surface / measuring track must be

flat. Buckles or bumps will lead to measuring in-

accuracies.

For applications which do not allow properly glueing of the mag-

netic strip, it can be inserted into a profile rail (accessory) - e.g.

rail type PS or PS1 thus forming a compact mounting unit.

For technical reasons the strip should be min.

56mm longer than the actual measuring distance.

Attention! To guarantee optimal adhesion oil,

grease dust etc. must be removed by using clean-

sing agents which evaporate without leaving resi-

dues. Suitable cleansing agents are e.g. ketones

(acetone) or alcohols; Messrs. Loctite and 3M can

both supply such cleansing liquid. Make sure that

the surface to be glued is dry and apply the strip

with maximum pressure. Glueing should preferably

be undertaken at temperatures between 20°C to

30°C and in dry atmosphere.

Advice! When applying long pieces of magnetic

strip do not immediately remove the complete

protective foil, but rather peel back a short part

from the end sufficient to fix the strip. Now align

the strip. As the protective strip is then peeled

back and out press the tape firmly onto the moun-

ting surface. A wall paper roller wheel could be

used to assist in applying pressure onto the mag-

netic strip when fixing it in position.

Mounting steps (see fig. 1)

Clean mounting surface (1) carefully.

Remove protective foil (2) from the adhesive

side of the magnetic strip (3).

Stick down the magnetic strip (4).

Clean surface of magnetic strip carefully.

Remove protective foil (6) from adhesive tape on

the cover strip (5).

•

•

•

•

•

User Information

MSK5000 Magnetic sensor

MB500 Magnetic strip

MR500 Magnetic ring

batch number

reference point

carrier strip

accuracy

MB type

MBxxxx GEK WT RP NNNNNN

Loading...

Loading...