MSK5000+MB500+MR500 Datum 21.09.2010 Art.Nr. 83109 Änd. Stand 318/10 9

Fig. 6: Definition of the counting direction with

magnetic strip and assemblage sensor/magnetic ring,

gap measure, tolerances

Position of the reference point R = as

stated in the delivery documentation

Position of the reference point E = as stated

in the delivery documentation; min. 0,05m

Magnetic poles -

schema

Unique reference point

Periodical reference point

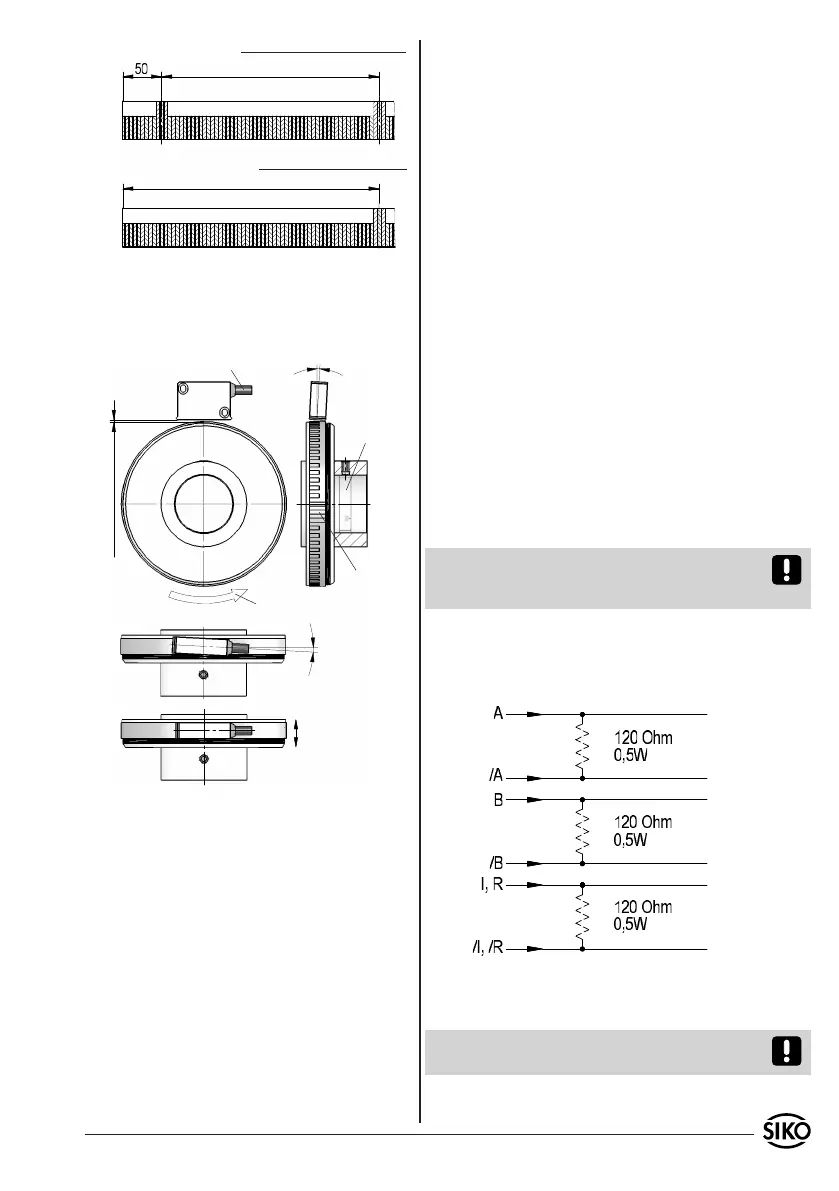

Fig.7: Definition of the counting direction with ma-

gnetic ring and assemblage sensor/magnetic ring,

gap measure, tolerances

Und e rc ut

at the solid

shaft for

tread plug

is recom-

mended

Signal

A before B

Direction of rotation

of magnetic ring

0.1mm ... 2.0mm without reference point

0.1mm ... 1.5mm with reference point

reference

point

Direction of outgoing cable

Admissable deviatoion

middle of tape/sensor:

without ref. point ±2mm

with ref. point ±0.5mm

< 3°

< 3°

RADIAL application MSK5000 with MR500:

(e.g. interference caused by SMPS, motors, cyclic

controls and contactors).

Necessary measures:

Only screened cable should be used. Wire cross sec-

tion is to be at least 0,14mm², max. 0,5mm².

Wiring to the screen and ground (0V) must

be secured to a good point. Ensure that the

connection of the screen and earth is made to

a large surface area with a sound connection to

minimise impedance.

The system should be positioned well away from

cables with interference; if necessary a protective

screen or metal housing must be provided. The

running of wiring parallel to the mains supply

should be avoided.

Contactor coils must be linked with spark sup-

pression.

Supply voltage

The voltages depend on the sensor designs; they

are to be taken from the delivery documentation

and the identification plate.

e.g.: 6,5VDC ... 30VDC

Attention! When connecting sensor and follower

electronics, please do not exceed the max. admis-

sable cable length.

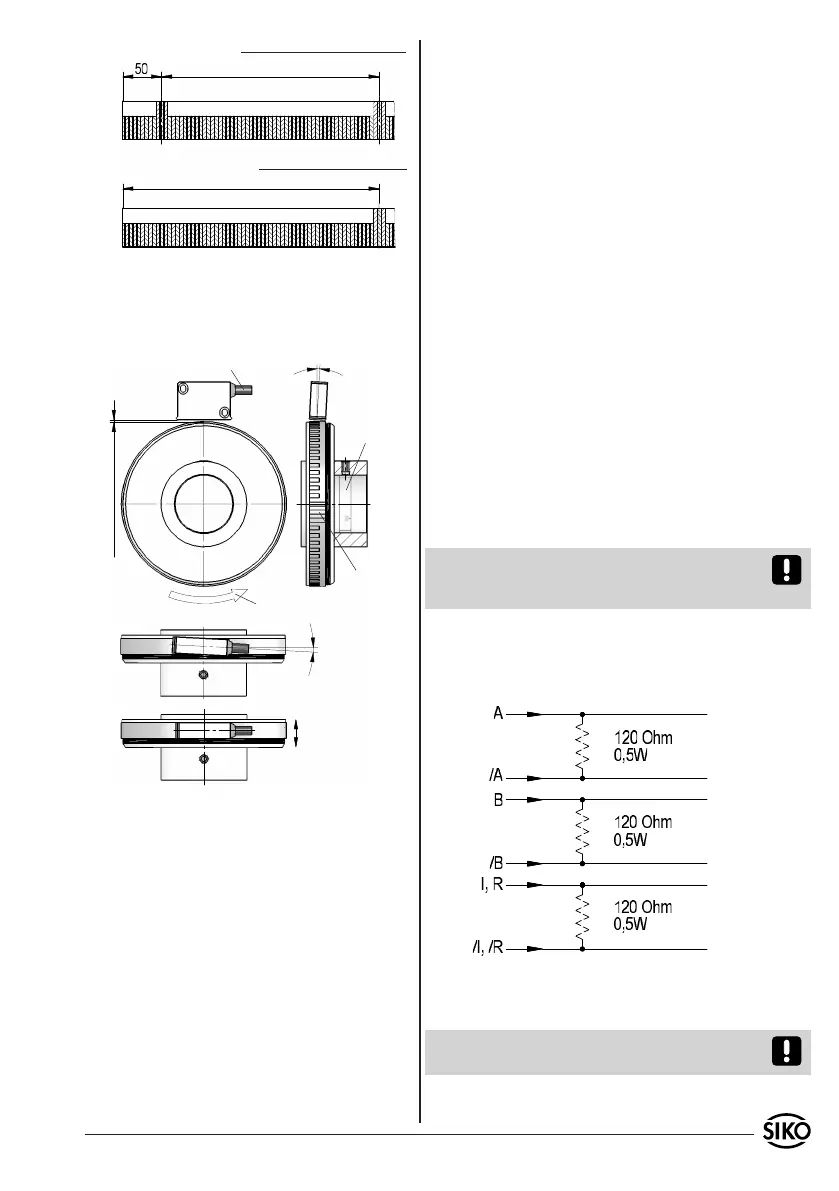

4.1 Connection note acc. to RS422 standard

Please provide the channels with a 120 Ohm ter-

minating resistor.

•

•

•

•

4. Electrical connection

Wiring must only be carried out with power off!

Check all lines and connections before switching

on the equipment!

Interference and distortion

All connections are protected against the effects

of interference. The location should be selected

to ensure that no capacitive or inductive in-

terferences can affect the sensor or the con-

nection lines! Suitable wiring layout and choice

of cable can minimise the effects of interference

•

•

4.2 Connection type

E1: Flying leads.

Attention! Tinned strands must not used in com-

bination with screw/clamp connections.

Loading...

Loading...