4.1 D.H.W. PRODUCTION

The preparation of hot water is guaranteed

by the tank unit in glass enamelled steel

with magnesium anode for the protection of

the tank unit and inspection flange for its

control and cleaning.

The magnesium anode must be checked

annually and substituted when it is worn.

If the boiler does not produce hot water,

make sure that the air has been released

by pressing on the manual outlets after

having switched off the main switch.

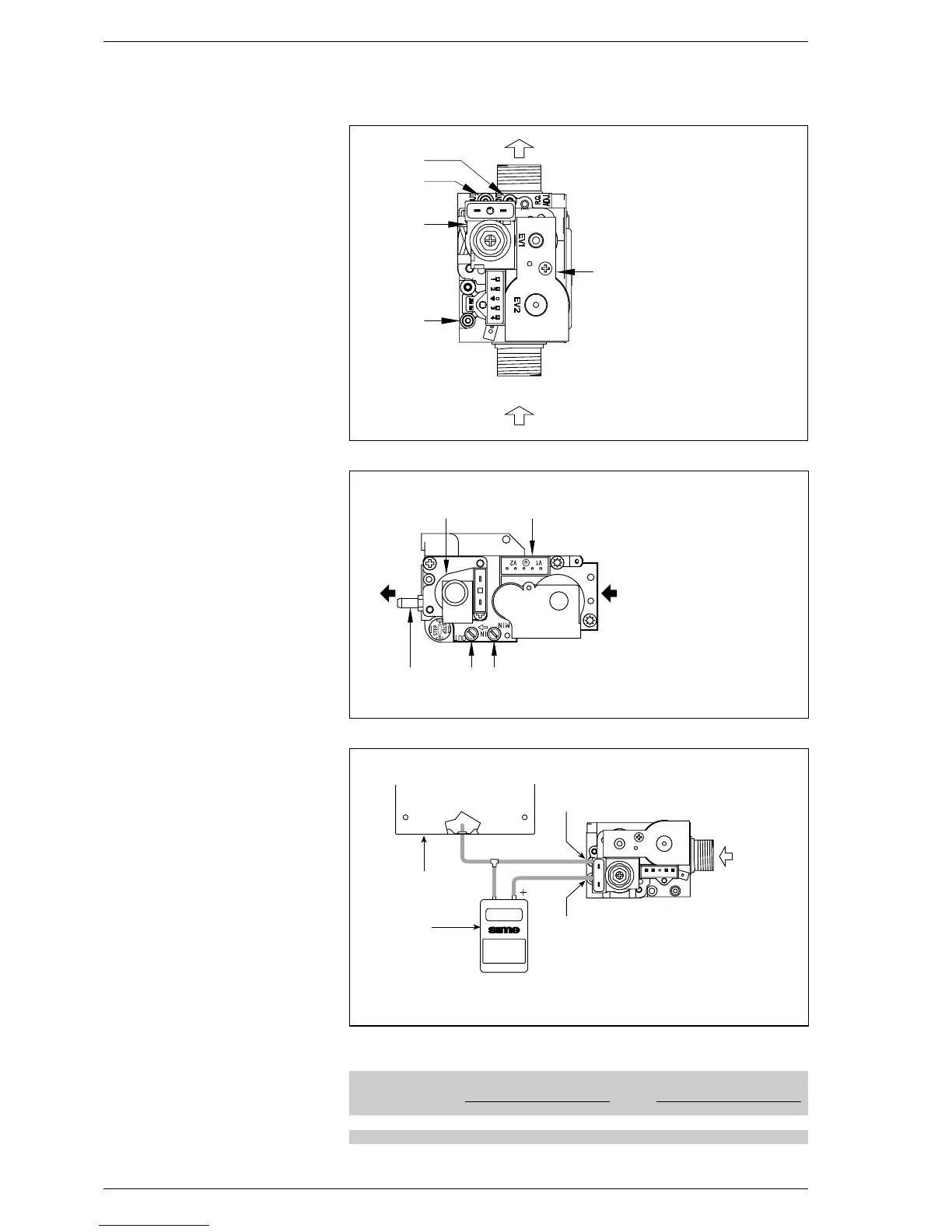

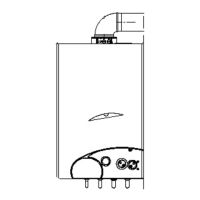

4.2 GAS VALVE

The boiler is produced with gas valve model

SIT 845 SIGMA (fig. 26) and gas valve

model HONEYWELL VK 4105M (fig. 27).

The gas valve is set at two pressure values:

maximum and minimum, that correspond,

according to the type of gas, to the values

indicated in Table 4.

The setting of the gas pressure at minimum

and maximum values is carried out by SIME:

variations are discouraged. Only in the pas-

sing from one type of gas supply (methane)

to another (propane) is a change in the

working pressure allowed.

Such an operation must be carried out by

authorised personnel, or the guarantee

will lose validity. Once the change in

working pressure has been carried out,

seal the regulators.

When the gas pressures are to be reset,

this must be done following a set order

first

setting the MAXIMUM and then the MINI-

MUM.

4.2.1 Maximum and minimum

pressure adjustment

SIT 845 SIGMA (fig. 29):

In order to carry out the setting of the maxi-

mum pressure proceed in the following way:

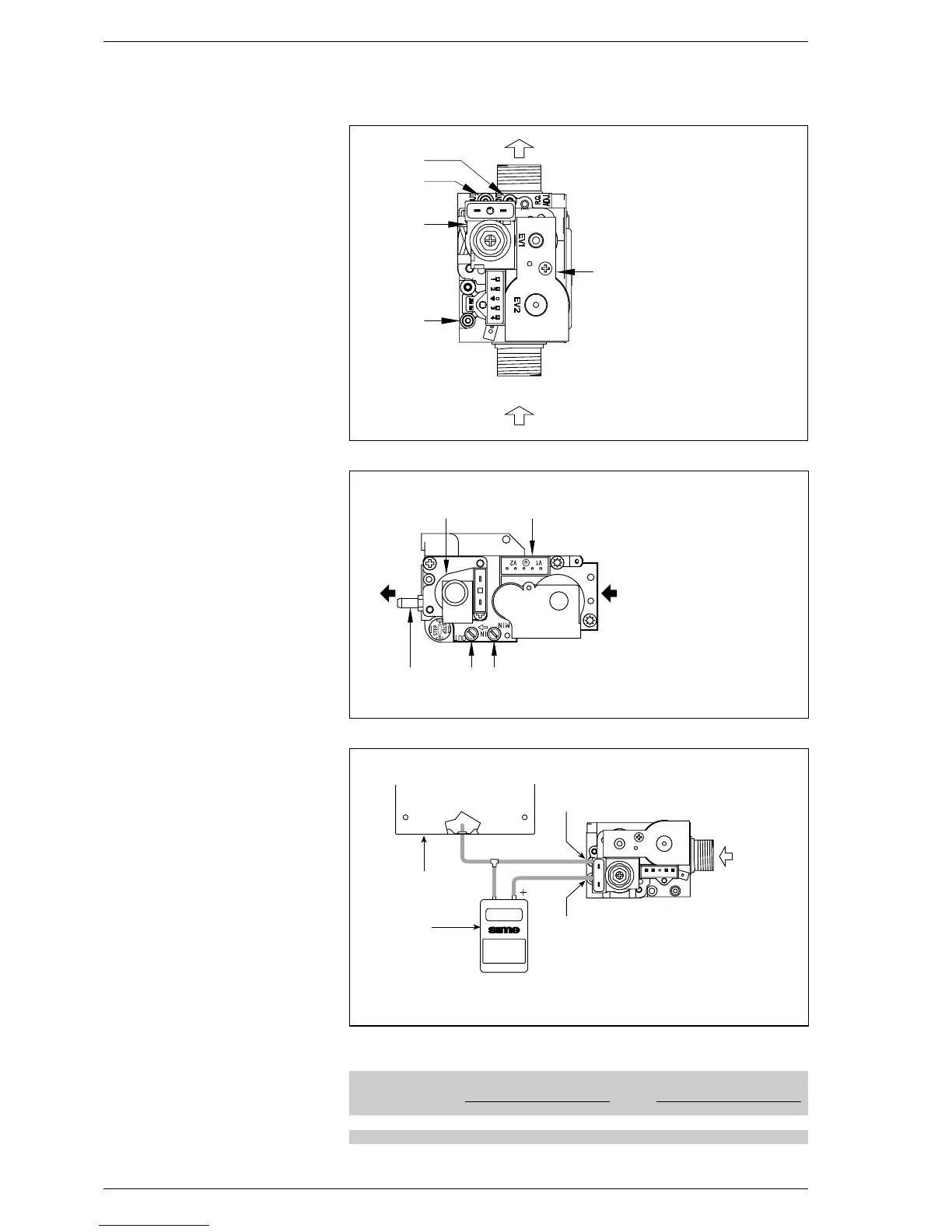

– Connect the manometer to the down-

stream pressure plug of the gas valve.

In the “BF” versions, instead, connect

the manometer as shown in fig. 28.

–

Remove the plastic cap of the modulator (1).

– Place the heating potentiometer knob on

the maximum value.

– Start the boiler by pressing on the four

way switch and the hot water cock.

– Using a ø 10 wrench turn the nut (3) to

find the maximum pressure as shown in

Table 4: to reduce the pressure turn the

nut anti-clockwise, to increase the pres-

sure turn the nut clockwise.

– Turn off and turn on the burner a few

times whilst keeping the hot water tap

constantly open to verify that the pressu-

re corresponds to the values given in

Table 4.

After having regulated the maximum pres-

sure, proceed with the setting of the mini-

mum pressure:

87

4 USE AND MAINTENANCE

Loading...

Loading...