51

EN

2.11 ELECTRICAL WIRING

If you must replace the electric power cable

supplied with the boiler, order it exclusively

from Sime. The power supply must be

single-phase 230V - 50 Hz through a main

switch protected by a fuse with a distance of

at least 3 mm between contacts.

The boiler must be connected with an effi-

cient grounding system. SIME shall not be

held liable for injury or damage resulting

from failure to ground the boiler.

ATTENTION: Before every intervention on

the boiler, cut off the electricity supply by

means of the main switch of the system,

since even if the boiler is “OFF”, the elec-

trical panel remains connected to the

electricity.

2.11.1 Chronothermostat connection

Connect the chronothermostat as indica-

ted in the boiler electrical diagram (see

paragraph 2.12) after having removed the

existing bridge.

The chronothermostat to be used must be

of a class conforming to the standard EN

607301 (clean electrical contact).

2.11.3 Remote control SIME HOME

connection (optional)

The boiler is designed for connection to a

remote control unit, supplied on request

(code 8092280/81).

The remote control unit SIME HOME allows

for complete remote control of the boiler.

The boiler display will show the following

message:

For installation and use of the remote con-

trol, follow the instructions in the package.

NOTE: Ensure PAR 10 set to 1

(PAR 10 = 1).

2.11.4 External sensor connection

The boiler is designed for connection to an

external temperature sensor, supplied on

request (code 8094101), which can auto-

matically regulate the temperature value of

the boiler output according to the external

temperature.

For installation, follow the instruction in the

package.

For installation, follow the instruction in the

package.

It is possible to make corrections

to the values read by the drill acting on the

PAR 11.

2.11.5 D.H.W. sensor connection in vers.

“20-25 BFT”

The “20-25 BFT” version is provided with

D.H.W. sensor (SB) linked to the connector

CN5. When the boiler is coupled to D.H.W.

storage tank, introduce the sensor into the

special sleeve in the D.H.W. storage tank.

ATTENTION: The “BFT” version is designed

for connection to D.H.W. storage tank, for

use ONLY FOR HEATING it is necessary:

- to disconnect the D.H.W. sensor (SB);

- set PAR 2=4.

All modules are designed to be used by

qualified technical personnel.

1. Visualizzazione temperatura esterna

solo con sonda esterna collegata

2. Visualizzazione temperatura sonda

riscaldamento (SM)

3. Visualizzazione temperatura sonda

sanitario (SS) solo per caldaie istantanee

4. Visualizzazione temperatura sonda

ausiliaria o sonda bollitore (SB)

6. Visualizzazione temperatura

riscaldamento riferita al primo circuito

7. Visualizzazione temperatura

riscaldamento riferita al secondo circuito

13. Visualizzazione codice errore

penultima anomalia

14. Visualizzazione numero totale

delle anomalie

10. Visualizzazione ore di funzionamento del bruciatore in h x 100 (es. 14.000 e 10)

11. Visualizzazione numero di accensioni del bruciatore x 1.000 (es. 97.000 e 500)

12. Visualizzazione codice errore

ultima anomalia

15. Contatore accessi parametri

installatore (es. 140 accessi)

5. Visualizzazione temperatura sonda

fumi

8. Visualizzazione corrente

di ionizzazione in µA

16. Contatore accessi parametri

OEM (es. 48 accessi)

9. Visualizzazione corrente al

modulatore in mA

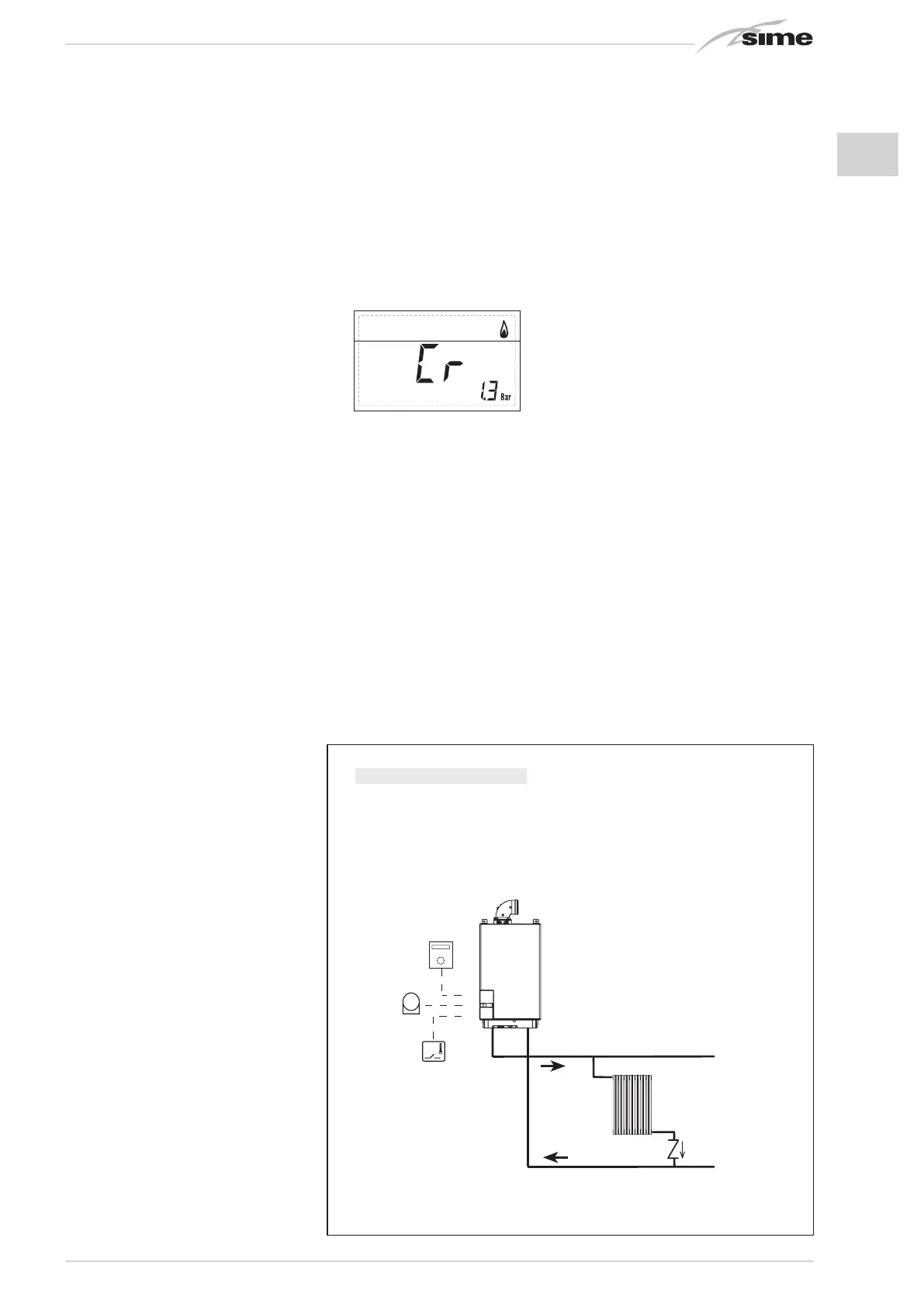

2.11.6 Use with different

electronic systems

Some examples are given below of boiler

systems combined with different electronic

systems. Where necessary, the parame-

ters to be set in the boiler are given. The

electrical connections to the boiler refer

to the wording on the diagrams (figs. 13 -

13/a - 13/b).

The zone valve control starts at every

demand for heating of the zone 1 (it is from

part of the TA1 or the CR).

Description of the letters indicating the

components shown on the system dia-

grams from 1 to 14:

M System output

R System return

CR Remote control SIME HOME

SE External temperature sensor

TA 1-2-3-4 Zone room thermostat

CT 1-2 Zone c

hronothermostat

VZ 1-2 Zone valve

RL 1-2-3-4 Zone relay

Sl Hydraulic separator

P 1-2-3-4 Zone pump

SB D.H.W. sensor

PB D.H.W. pump

IP Floor system

EXP Expansion card ZONA MIX (code

8092234)/INSOL (code 8092235)

VM Three-way mixer valve

RM

SE

TA3

TA1

SE

SI

RL3

P3

P2

TA2

IP

EXP

VM

EXP

IP

P4

TA4

RL4

TA1

TA2

SI

RM

SE

TA1

TA2

TA2

SE

TA

P2

RL

RL1

RL2

P1

P

CR

CR

RM

SE

CT2

TA1

SE

CT1

TA2

VZ1

VZ2

ZONA

GIORNO

(70¡C)

ZONA

NOTTE

(50¡C)

RM

SE

CT2

TA1

SE

CT1

SI

RL2

P2

P1

TA2

RL1

ZONA

GIORNO

(70¡C)

ZONA

NOTTE

(50¡C)

RM

SE

TA2

TA1

SE

TA1

SI

RL2

P2

P1

TA2

CR

CR

EXP

VM

EXP

RM

SE

TA2

TA1

SE

TA1

SI

RL2

P2

P1

PB

RL1

BOLLITORE

PB

SB

SB

IP

RM

SE

TA1

TA2

TA1

SE

TA

P2

RL

SI

RL1

RL2

P1

P

TA2

SE

RM

SE

VZ

VZ1

TA2

VZ2

CR

CR

VZ1

TA1

TA2

SE

RM

SE

TA

VZ

TA1

VZ1

TA2

VZ2

CR

CR

TA1

SE

RM

SE

TA

VZ

TA1

VZ1

TA2

VZ2

R

M

SE

TA

CR

TA1

CR

SE

R

M

SE

CR

CR

SE

SB

M2

R2

SB

BOLLITORE

S1

SB

S2

R

M

SE

TA1

SE

SI

P1

TA2

EXP

VM

EXP

IP

TA1

TA2

P2

VM

IP

EXP

EXP (INSOL)

Vers. BFT / T

RM

SE

TA1

SE

SI

P1

TA2

EXP

VM

EXP

IP

TA1

TA2

P2

VM

IP

EXP

1 BASIC SYSTEM

SYSTEM WITH A DIRECT ZONE AND ROOM THERMOSTAT, OR

WITH REMOTE CONTROL SIME HOME (Code 8092280/81)

AND EXTERNAL SENSOR (Code 8094101)

Loading...

Loading...